A1000 6-Phase/12-Pulse Input

Flange Mount and Non-Flange Mount

Installation Manual

Type: CIMR-AU4T

Models:

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

400 V Class: 30 to 355 kW (40 to 550 HP ND)

A and CIMR-AU4T U

MANUAL NO. TOEP YAIA1U 02A

Copyright © 2015 YASKAWA AMERICA, INC. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent

liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly

striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Preface

1 PREFACE…………………………………………………………………………………………………..4

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

3

1 Preface

1 Preface

Yaskawa manufactures products used as components in a wide variety of industrial systems and equipment. The selection and

application of Yaskawa products remain the responsibility of the equipment manufacturer or end user. Yaskawa accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All systems or equipment

designed to incorporate a product manufactured by Yaskawa must be supplied to the end user with appropriate warnings and

instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa must be promptly provided to

the end user. Yaskawa offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

Yaskawa assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

This manual is designed to ensure correct and suitable application of A1000-Series Drives with 6-Phase/12-Pulse rectification.

Read this manual before attempting to install or operate a drive and keep it in a safe, convenient location for future reference.

Be sure you understand all precautions and safety information before attempting application.

Use this manual as the primary reference to install and wire A1000 drives with 6-Phase/12-Pulse rectification together with

the A1000 Quick Start Guide and Technical Manual.

u

Product Overview

The A1000 6-Phase/12-Pulse drive design matches an isolation transformer with a tuned input reactor to provide a phase shift

that reduces harmonic distortion for cleaner power.

u

Applicable Documentation

The following manuals are available for A1000 series drives:

A1000 Series AC Drive 6-Phase/12-Pulse Input Installation Manual (TOEPYAIA1U02)

This guide is packaged together with the product and contains information required to install and wire the

drive with 6-Phase/12-Pulse rectification. This manual is available for download on our documentation

website, www.yaskawa.com.

A1000 Series AC Drive Quick Start Guide (TOEPC71061641)

This guide contains basic information required to install and wire the 3-Phase/6-Pulse drive and gives an

overview of fault diagnostics, maintenance, and parameter settings for 3-Phase/6-Pulse and 6-Phase/12Pulse drives. The purpose of this guide is to prepare the drive for a trial run with an application and for

basic operation. This manual is available for download on our documentation website,

www.yaskawa.com.

A1000 Series AC Drive Technical Manual (SIEPC71061641)

This manual provides detailed information on 3-Phase/6-Pulse and 6-Phase/12-Pulse parameter settings,

drive functions, and MEMOBUS/Modbus specifications. Use this manual to expand drive functionality

and to take advantage of higher performance features. This manual is available for download on our

documentation website, www.yaskawa.com.

u

Supplemental Safety Information

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details. Replace the covers or shields before

operating the drive and run the drive according to the instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and may not apply to all products to

which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be changed without notice

to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representative or the nearest Yaskawa sales

office and provide the manual number shown on the front cover.

• If nameplate becomes worn or damaged, order a replacement from your Yaskawa representative or the nearest Yaskawa sales office.

WARNING

Read and understand this manual before installing, operating or servicing this drive. The drive must be installed according

to this manual and local codes.

4

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

1 Preface

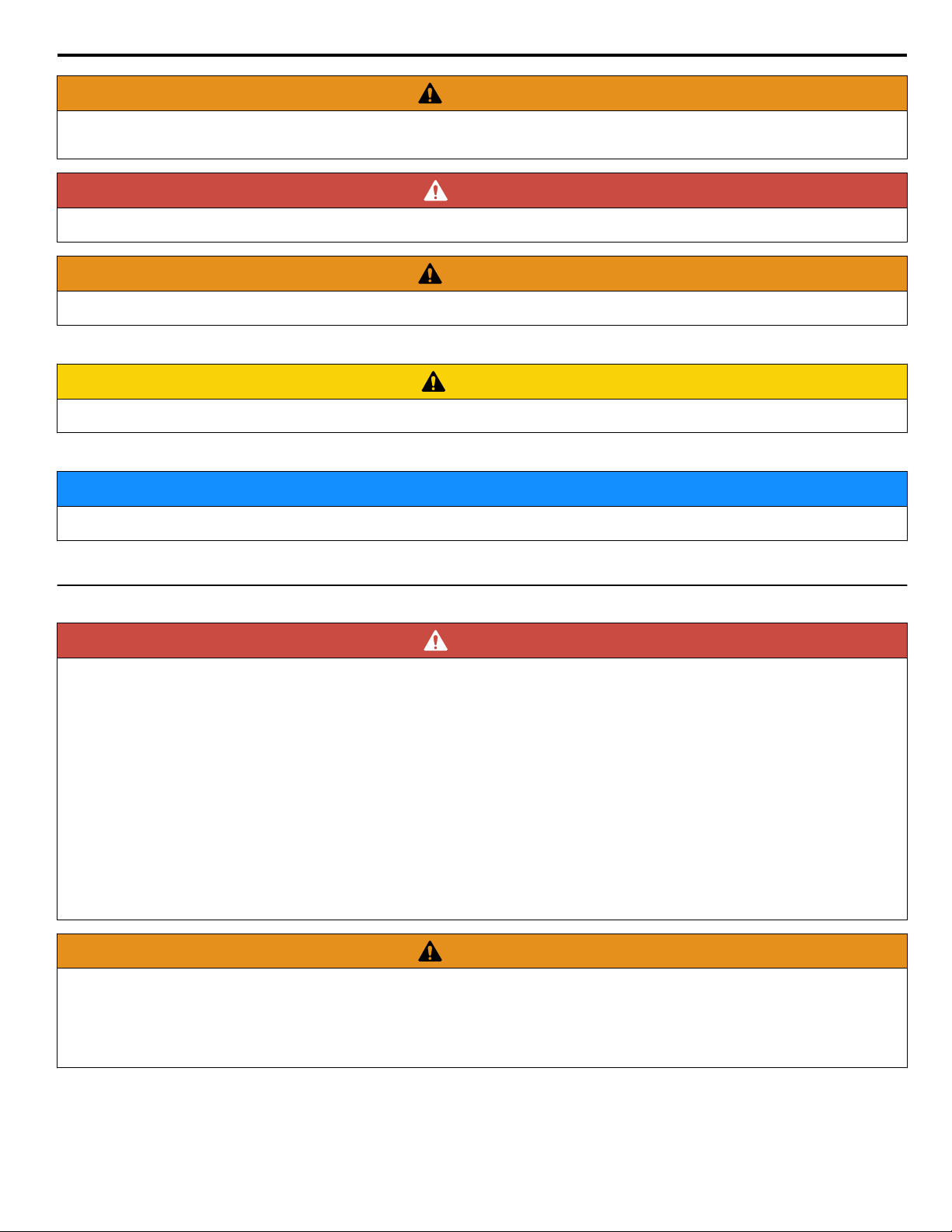

WARNING

The following conventions are used to indicate safety messages in this manual. Failure to heed these messages could result

in serious or fatal injury or damage to the products or to related equipment and systems.

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

WARNING! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

CAUTION! may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

NOTICE

Indicates a property damage message.

NOTICE: may also be indicated by a bold key word embedded in the text followed by an italicized safety message.

u

Safety Messages

DANGER

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operating company is responsible for any injuries or equipment damage resulting from failure to heed the warnings in

this manual.

Electrical Shock Hazard

Before servicing, disconnect all power to the equipment.

The capacitor for the control power supply remains charged even after the power supply is turned off. The charge indicator

LED will extinguish when the control power supply voltage is below 50 Vdc. To prevent electric shock, wait for at least the

time specified on the warning label, once all indicators are OFF, measure for unsafe voltages to confirm the drive is safe

prior to servicing.

Failure to comply will result in death or serious injury.

WARNING

Sudden Movement Hazard

System may start unexpectedly upon application of power, resulting in death or serious injury.

Clear all personnel from the drive, motor and machine area before applying power. Secure covers, couplings, shaft keys and

machine loads before applying power to the drive.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

5

1 Preface

WARNING

Electrical Shock Hazard

Do not attempt to modify or alter the drive in any way not explained in this manual.

Failure to comply could result in death or serious injury.

Yaskawa is not responsible for any modification of the product made by the user. This product must not be modified.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Installation, maintenance, inspection, and service must be performed only by authorized personnel familiar with installation,

adjustment and maintenance of AC drives.

Do not remove covers or touch circuit boards while the power is on.

Failure to comply could result in death or serious injury.

Make sure the protective earthing conductor complies with technical standards and local safety regulations.

Because the leakage current exceeds 3.5 mA in models 4o0302 and larger, IEC/EN 61800-5-1 states that either the power

supply must be automatically disconnected in case of discontinuity of the protective earthing conductor or a protective

earthing conductor with a cross-section of at least 10 mm2 (Cu) or 16 mm2 (Al) must be used. Failure to comply may result

in death or serious injury.

Always use appropriate equipment for Ground Fault Circuit Interrupters (GFCIs).

The drive can cause a residual current with a DC component in the protective earthing conductor. Where a residual current

operated protective or monitoring device is used for protection in case of direct or indirect contact, always use a type B GFCI

according to IEC/EN 60755.

Fire Hazard

Do not use an improper voltage source.

Failure to comply could result in death or serious injury by fire.

Verify that the rated voltage of the drive matches the voltage of the incoming power supply before applying power.

Install adequate branch circuit protection according to applicable local codes and this Installation Manual. Failure

to comply could result in fire and damage to the drive or injury to personnel.

The device is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 480 Vac

maximum (400 V class), when protected by branch circuit protection devices specified in this manual.

Crush Hazard

Do not use this drive in lifting applications without installing external safety circuitry to prevent accidental dropping

of the load.

The drive does not possess built-in load drop protection for lifting applications.

Failure to comply could result in death or serious injury from falling loads.

Install electrical and/or mechanical safety circuit mechanisms independent of drive circuitry.

CAUTION

Crush Hazard

Do not carry the drive by the front cover.

Failure to comply may result in minor or moderate injury from the main body of the drive falling.

6

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

1 Preface

NOTICE

Observe proper electrostatic discharge procedures (ESD) when handling the drive and circuit boards. Failure to

comply may result in ESD damage to the drive circuitry.

Do not perform a withstand voltage test on any part of the drive.

Failure to comply could result in damage to the sensitive devices within the drive.

Do not operate damaged equipment.

Failure to comply could result in further damage to the equipment. Do not connect or operate any equipment with visible

damage or missing parts.

If a fuse is blown or a Ground Fault Circuit Interrupter (GFCI) is tripped, check the wiring and the selection of the

peripheral devices.

Contact your supplier if the cause cannot be identified after checking the above.

Do not restart the drive immediately operate the peripheral devices if a fuse is blown or a GFCI is tripped.

Check the wiring and the selection of peripheral devices to identify the cause. Contact your supplier before restarting the

drive or the peripheral devices if the cause cannot be identified.

Do not expose the drive to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the drive.

Do not pack the drive in wooden materials that have been fumigated or sterilized. Do not sterilize the entire package after

the product is packed.

General Application Precautions

n

Selection

Installing a Transformer

Install a 6-Phase/12-Pulse isolation transformer with each of the output windings phase shifted by 30 electrical degrees or

install a Hybrid 6-Phase topology on the power supply.

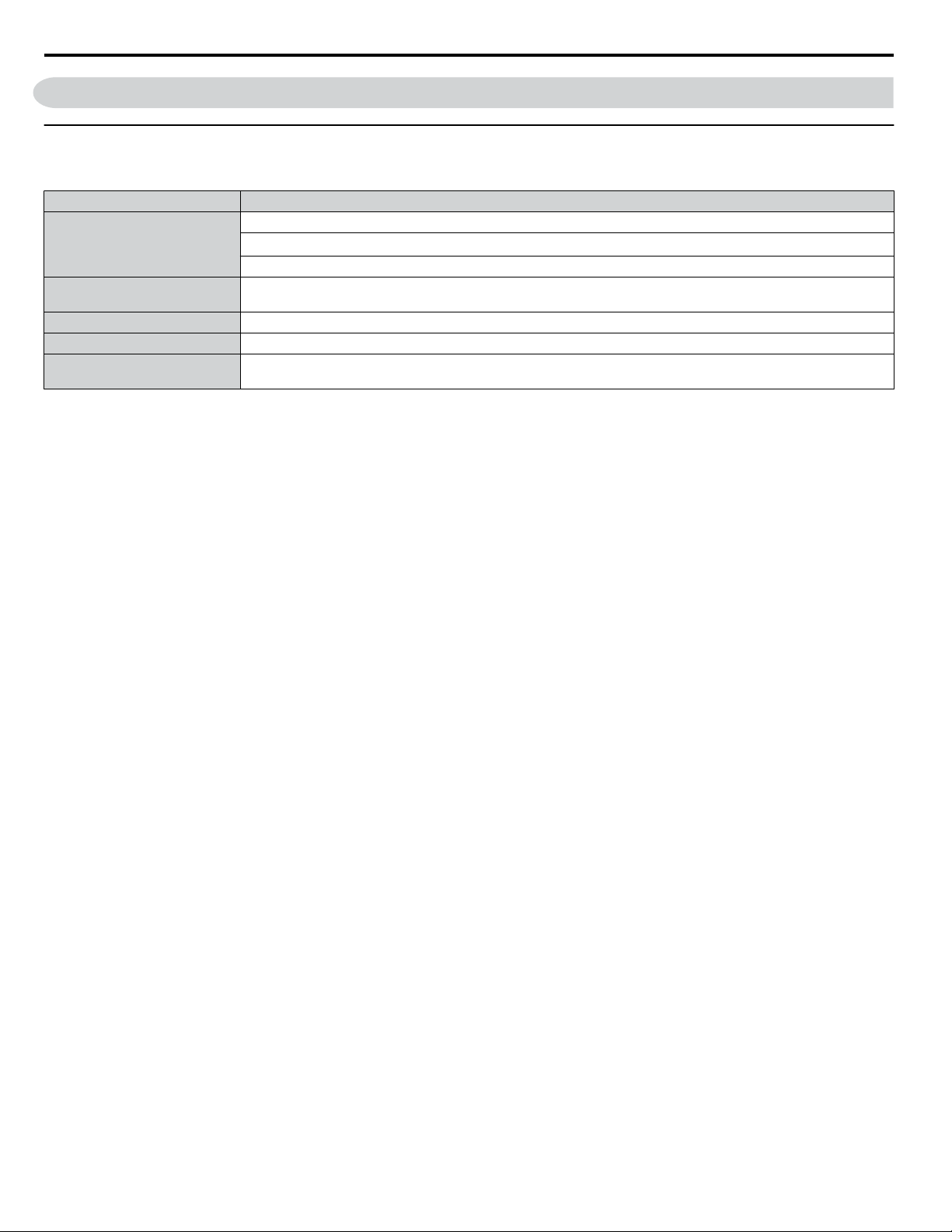

Installing a Reactor

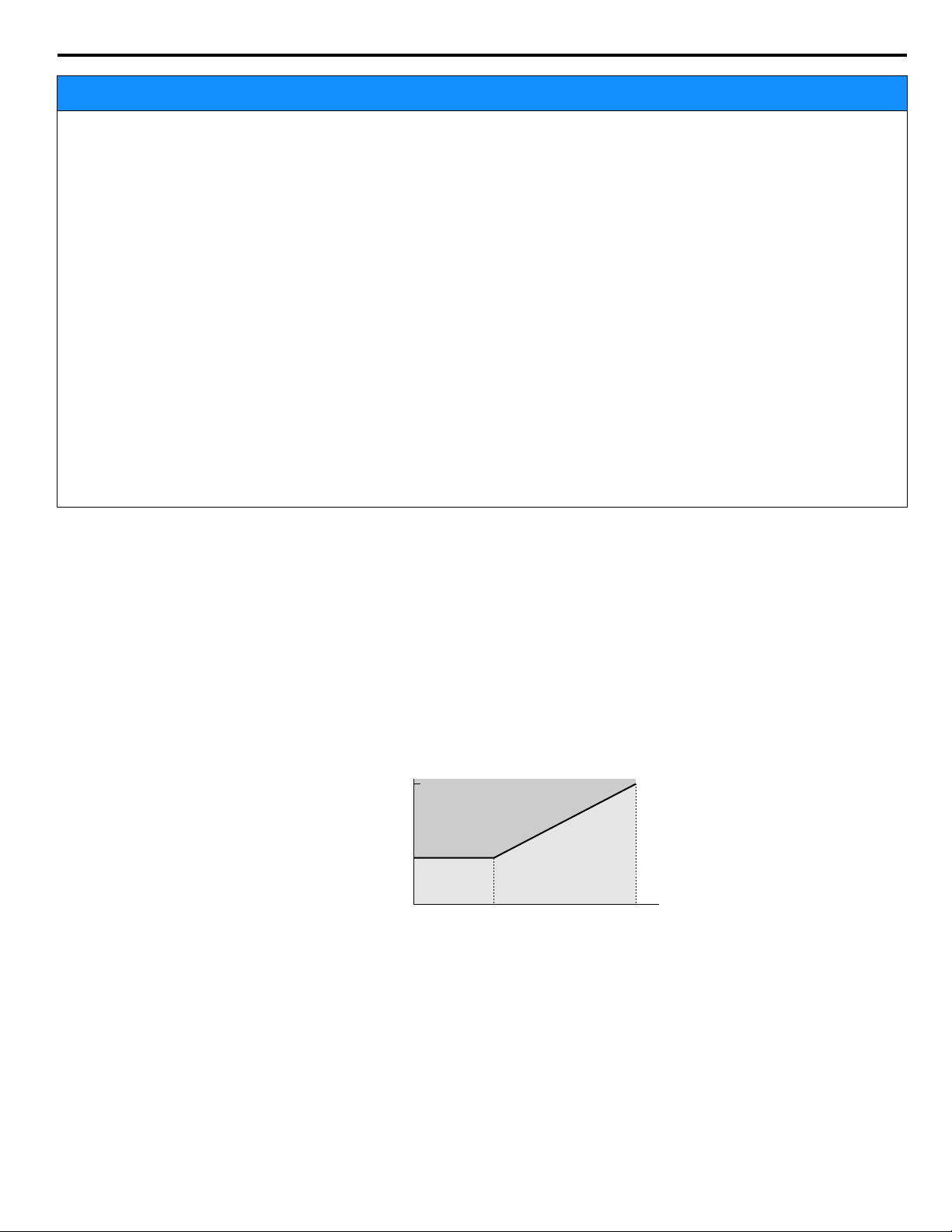

Use an AC reactor or DC link choke in the following situations:

• to suppress harmonic current.

• to smooth peak current that results from capacitor switching.

• when the power supply is above 600 kVA.

• when the drive is running from a power supply system with thyristor converters.

4000

Power supply harmonics

reactor required

Power Supply

Capacity (kVA)

600

0

Drive Capacity (kVA)

Figure Installing a Reactor

Reactor

unnecessary

60 400

Inspection and Maintenance

WARNING! Electrical Shock Hazard. Capacitors for the control power supply do not immediately discharge after shutting off the power.

Wait for at least the amount of time specified on the drive before touching any components after shutting off the power. Failure to comply

may cause injury to personnel from electrical shock.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

7

1 Preface

WARNING! Electrical Shock Hazard. When a drive is running a PM motor, voltage continues to be generated at the motor terminals after

the drive is shut off while the motor coasts to stop. Take the precautions described below to prevent shock and injury:

∙ In applications where the machine can still rotate after the drive has fully stopped a load, install a switch to the drive output side to disconnect

the motor and the drive.

∙ Do not allow an external force to rotate the motor beyond the maximum allowable speed or to rotate the motor when the drive has been

shut off.

∙ Wait for at least the time specified on the warning label after opening the load switch on the output side before inspecting the drive or

performing any maintenance.

∙ Do not open and close the load switch while the motor is running.

∙ If the motor is coasting, make sure the power to the drive is turned on and the drive output has completely stopped before closing the load

switch.

WARNING! Burn Hazard. Because the heatsink can get very hot during operation, take proper precautions to prevent burns. When replacing

the cooling fan, shut off the power and wait at least 15 minutes to be sure that the heatsink has cooled down. Failure to comply may cause

burn injury to personnel.

Wiring

All wire ends should use ring terminals for UL/cUL compliance. Use only the tools recommended by the terminal manufacturer

for crimping.

Transporting the Drive

NOTICE: Never steam clean the drive. During transport, keep the drive from coming into contact with salts, fluorine, bromine, phthalate

ester, and other such harmful chemicals.

u

Drive Label Warning Example

Always heed the warning information listed in Figure .

WARNING

Risk of electric shock.

●

Read manual before installing.

●

Wait 5 minutes for capacitor

discharge after disconnecting

power supply.

●

To conform to requirements,

make sure to ground the supply

neutral for 400V class.

●

After opening the manual switch

between the drive and motor,

please wait 5 minutes before

inspecting, performing

maintenance or wiring the drive.

Hot surfaces

●

Top and Side surfaces may

become hot. Do not touch.

Figure Warning Information Example

u

Warranty Information

Restrictions

n

The drive is not designed or manufactured for use in devices or systems that may directly affect or threaten human lives or

health.

Customers who intend to use the product described in this manual for devices or systems relating to transportation, health

care, space aviation, atomic power, electric power, or in underwater applications must first contact their Yaskawa

representatives or the nearest Yaskawa sales office.

WARNING! Injury to Personnel. This product has been manufactured under strict quality-control guidelines. However, if this product is to

be installed in any location where failure of this product could involve or result in a life-and-death situation or loss of human life or in a facility

where failure may cause a serious accident or physical injury, safety devices must be installed to minimize the likelihood of any accident.

8

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

Installation Manual

1 RECEIVING………………………………………………………………………………………………10

2 MECHANICAL INSTALLATION…………………………………………………………………..13

3 ELECTRICAL INSTALLATION……………………………………………………………………15

4 START-UP PROGRAMMING & OPERATION……………………………………………….26

5 TROUBLESHOOTING………………………………………………………………………………..27

6 DRIVE OPTIONS AND PERIPHERAL DEVICES…………………………………………..29

7 PERIODIC INSPECTION & MAINTENANCE…………………………………………………35

8 SPECIFICATIONS……………………………………………………………………………………..38

9 PARAMETER TABLE………………………………………………………………………………..77

10 STANDARDS COMPLIANCE……………………………………………………………………..81

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

9

PRG : 1010

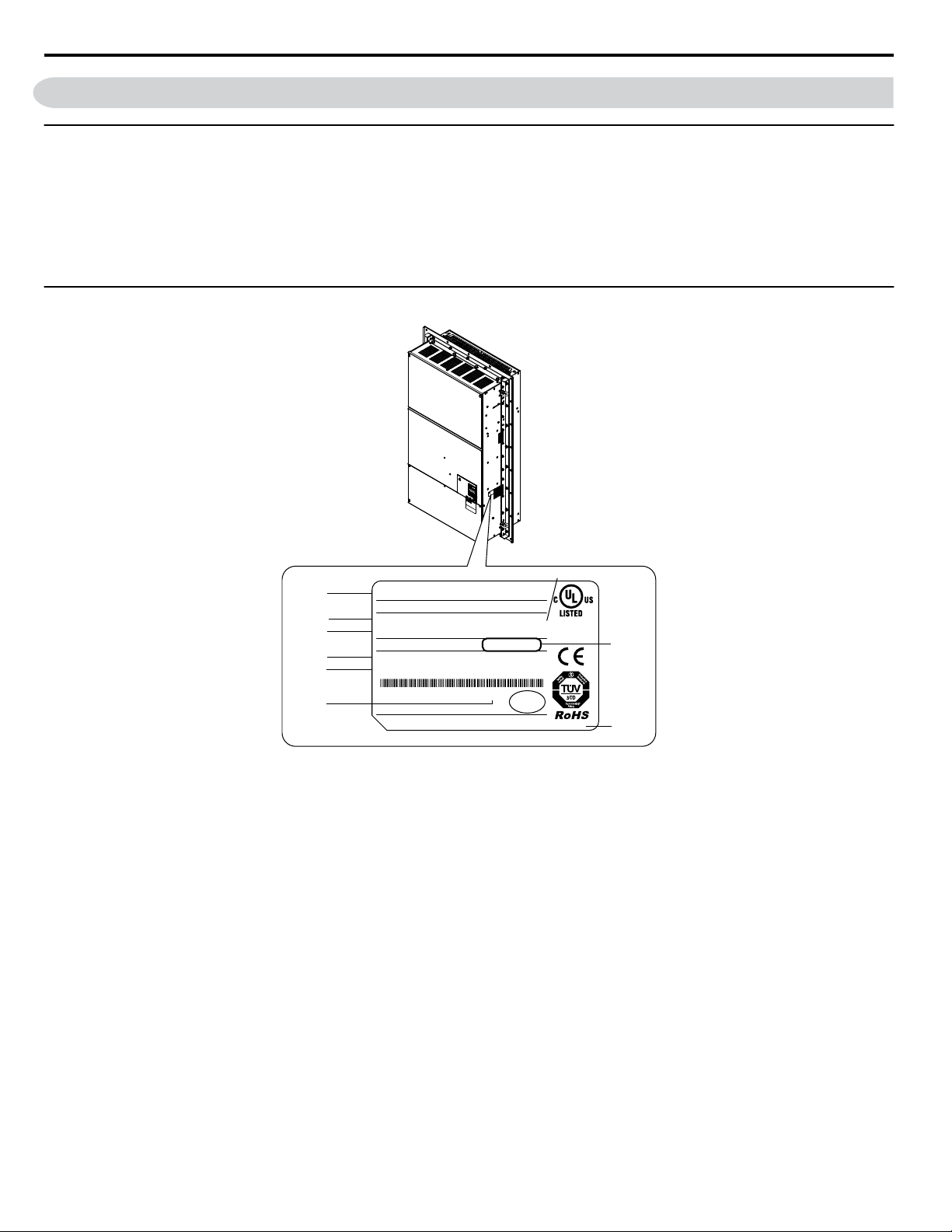

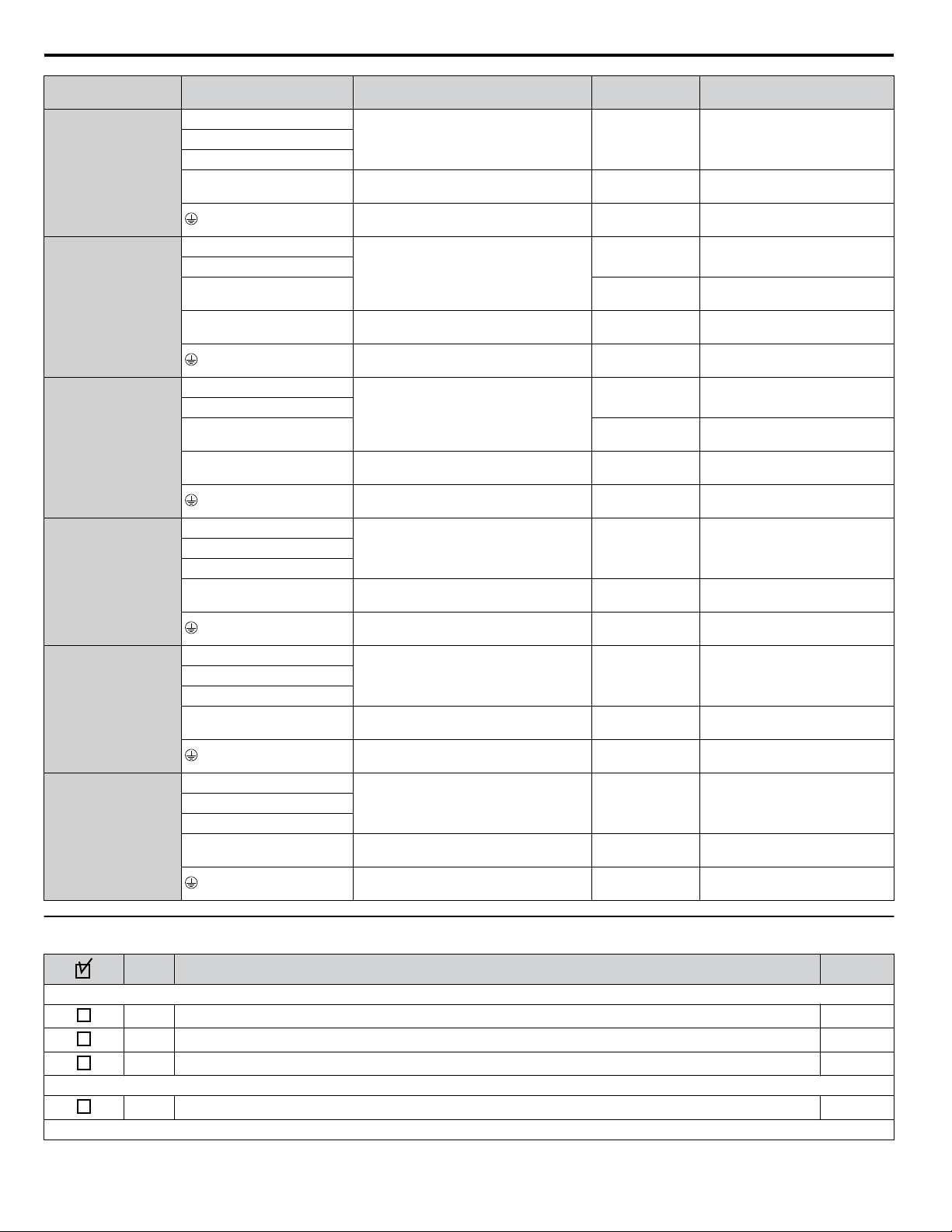

IND.CONT.EQ.

7J48

CIMR-AU4T0675UAA REV:A

:

:

AC6PH(12P) 380-480V 50/60Hz 603A/511A

: AC3PH 0-480V 0-400Hz 675A/605A

: 220kg

:

:

: E131457 IP00

PASS

MODEL

INPUT

OUTPUT

MASS

O / N

S / N

FILE NO

I

H

G

F

E

D

B

C

A

C/C CIMR-AU4T0675UAA

YASKAWA ELECTRIC CORPORATION

2-1 Kurosaki-shiroishi, Yahatanishi-ku, Kitakyushu 806-0004 Japan

MADE IN JAPAN

1 Receiving

1 Receiving

u

Model Number and Nameplate Check

Please perform the following tasks after receiving the drive:

• Inspect the drive for damage.

If the drive appears damaged upon receipt, contact the shipper immediately.

• Verify receipt of the correct model by checking the information on the nameplate.

• If you have received the wrong model or the drive does not function properly, contact your supplier.

u

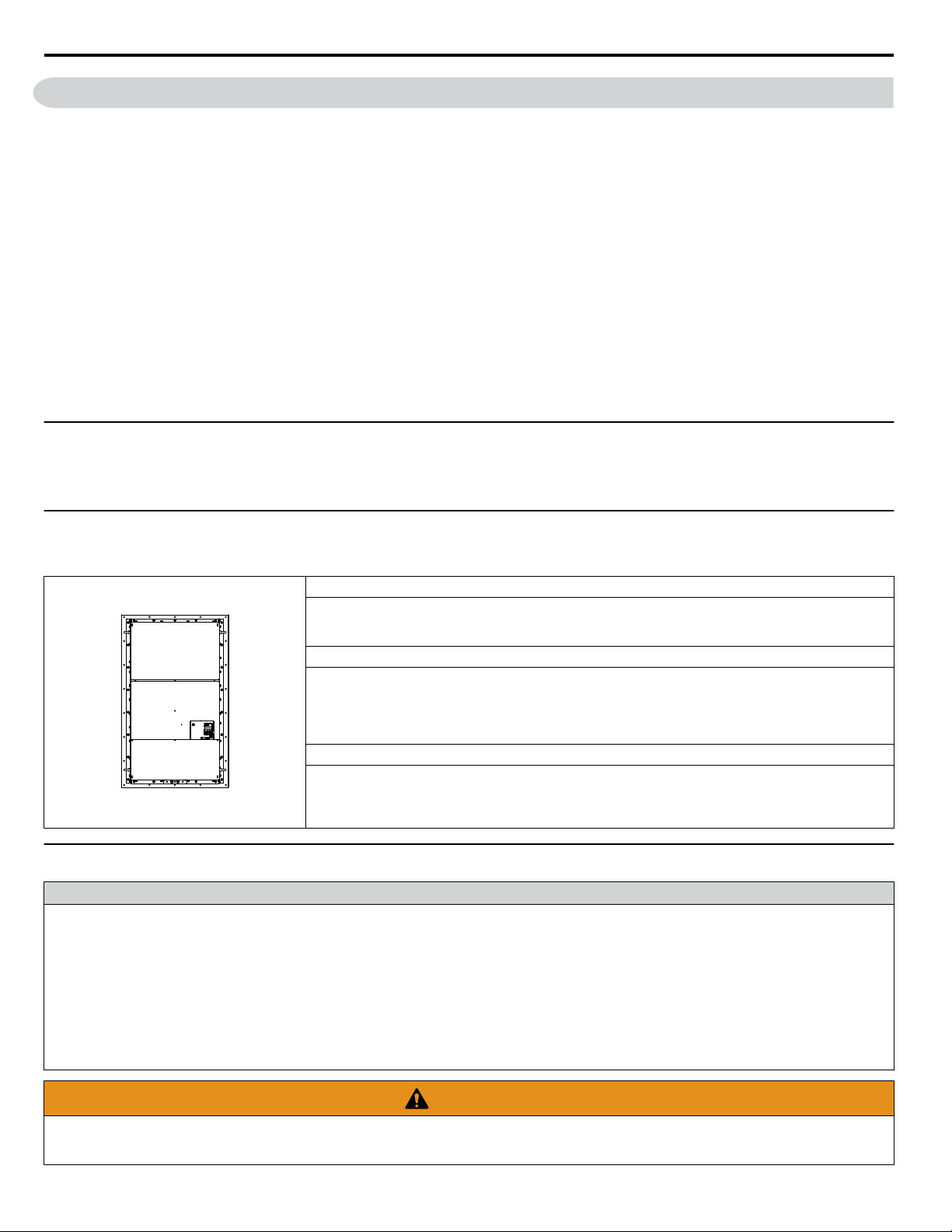

Nameplate

A – Normal Duty / Heavy Duty Amps

B – Software version

C –

Address

<1>

D – Enclosure type

F – Lot number

G – Output specifications

H – Input specifications

I – AC drive model

E – Serial number

Figure 1 Nameplate Information Example

<1> The address of the head office of Yaskawa Electric Corporation (responsible for product liability) is shown on the nameplate.

10

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

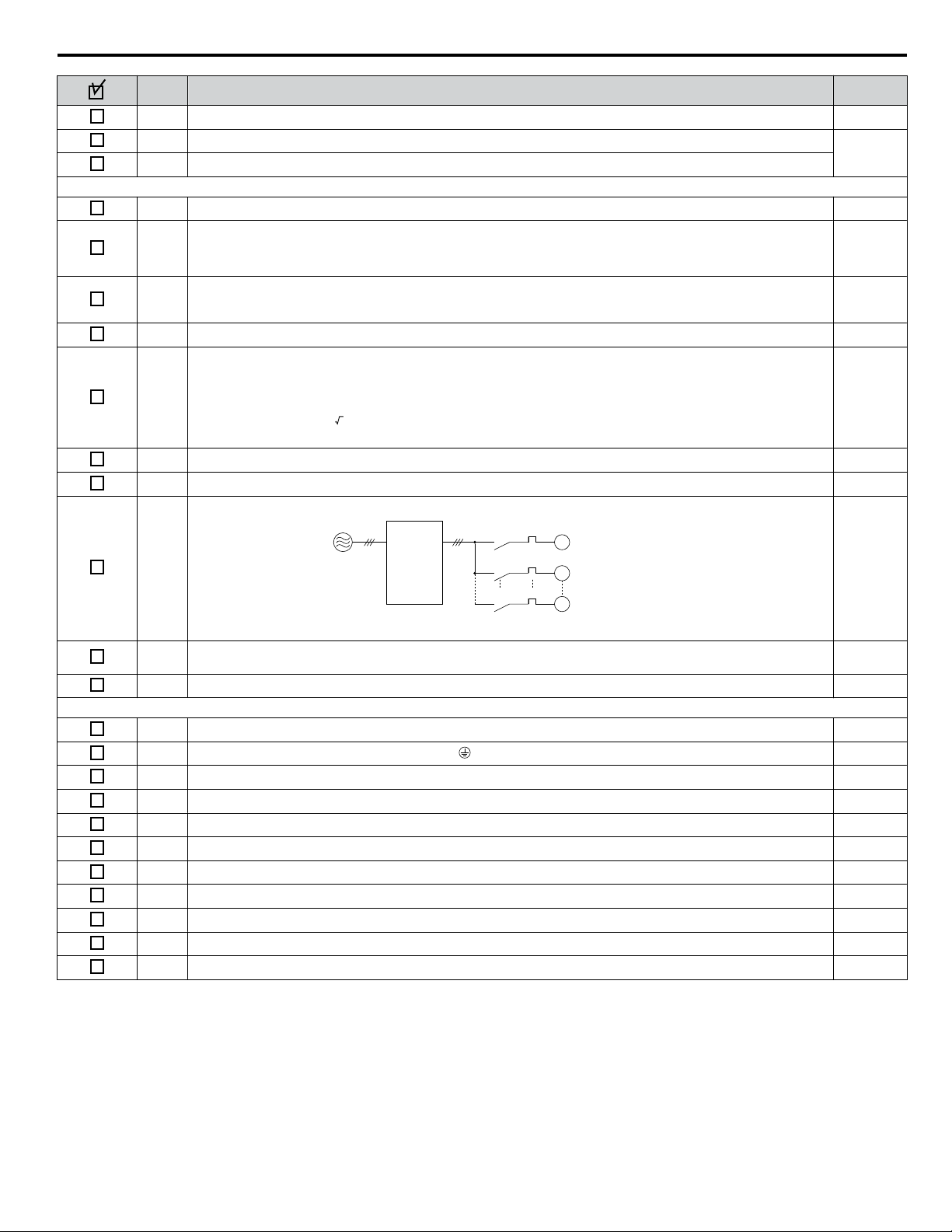

CIMR

—

A U 4 T

0675 U

A A

Drive

A1000

Series

Letter

Enclosure

Type

Design

Revision

Order

Letter

Region

Code

USA

No. Voltage Class

Letter

Environmental

Specification

A Standard

380-480 Vac 4

Customized

Specification

6-Phase/

12-Pulse Input

<2>

A

Refer to the tables below

Flange Type

U

<1>

U

Open Type

(Non-Flange)

1 Receiving

<1> Provides method of mounting drive with backside (heatsink) external to enclosure with NEMA 12 integrity.

<2> Drives with these specifications do not guarantee complete protection for the environmental conditions indicated.

6-Phase/12-Pulse 400 V Class Rated Output

n

Table 1 Model Number and Specifications (400 V Class)

Drive Model

4T0058o

4T0072o

4T0088o

4T0103o

4T0139o

4T0165o

4T0208o

4T0250o

4T0296o

4T0362o

4T0414o

4T0515o

4T0675o

Normal Duty (ND)

C6-01 = 1

Max. Motor Capacity

kW (HP)

30 (40) 58

37 (50) 72

45 (60) 88

55 (75) 103

75 (100) 139

90 (125) 165

110 (150) 208

132 (200) 250

160 (250) 296

185 (300) 362

220 (350) 414

250 (400-450) 515

355 (500-550) 675

Rated Output

Current A

Drive Model

4T0058o

4T0072o

4T0088o

4T0103o

4T0139o

4T0165o

4T0208o

4T0250o

4T0296o

4T0362o

4T0414o

4T0515o

4T0675o

Heavy Duty (HD)

C6-01 = 0

Max. Motor Capacity

kW (HP)

22 (25-30) 45

30 (40) 60

37 (50-60) 75

45 (50-60) 91

55 (75) 112

75 (100) 150

90 (125-150) 180

110 (150) 216

132 (200) 260

160 (250) 304

185 (300) 370

220 (350) 450

315

(400-450-500)

Rated Output

Current A

605

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

11

1 Receiving

u

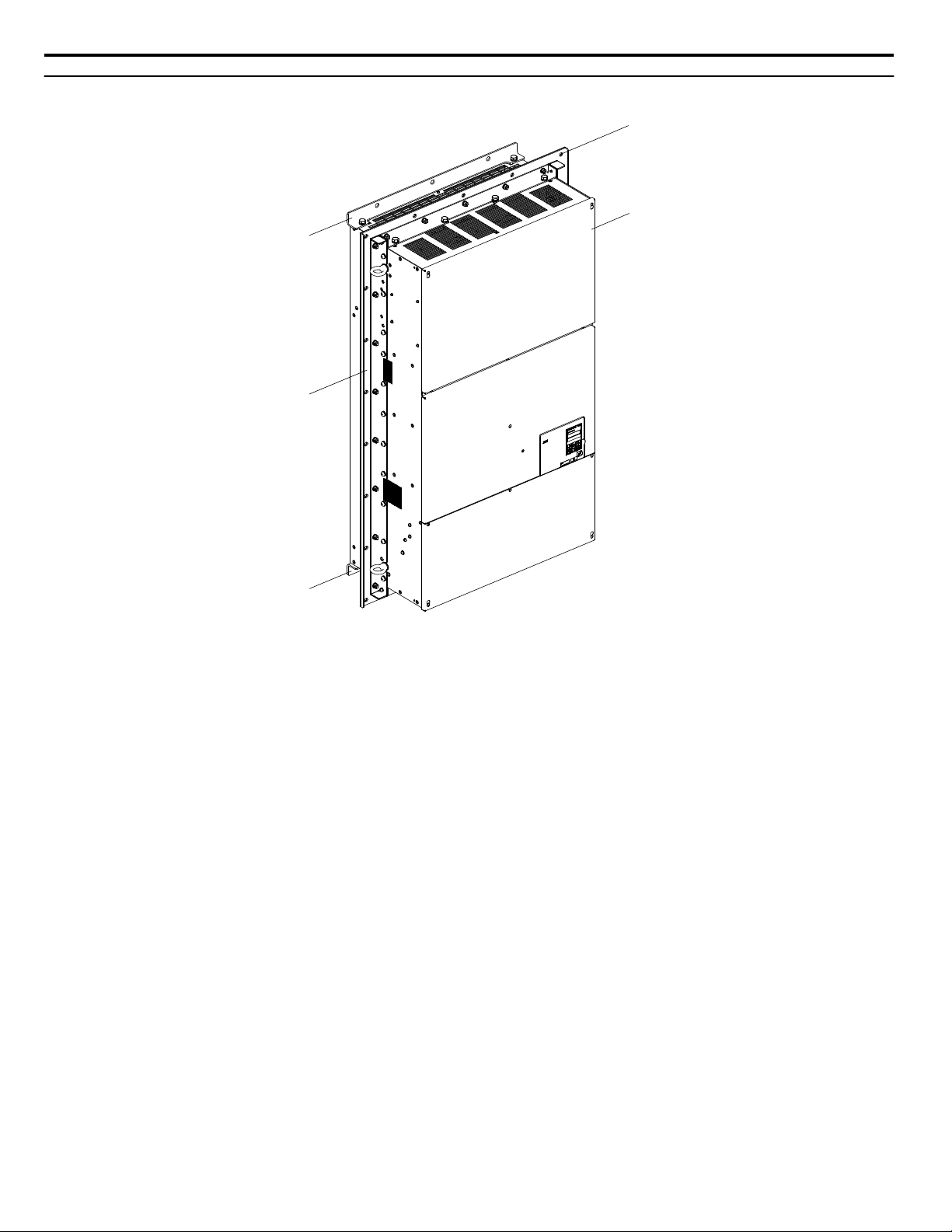

6-Phase/12-Pulse Component Names

A – Installation hole

B – 6-Phase/12-Pulse Drive

Figure 2 Flange Type Enclosure Example (Models 4TooooU)

<1> Provides method of mounting drive with backside (heatsink) external to enclosure with NEMA 12 integrity. 4TooooU models

only.

NOTICE: Remove the shipping package attachments before installing. The shipping package attachments will interfere with the cutting of

the panel when installing the drive.

C –

Mounting flange

D – Shipping package attachment (to

be removed before installation)

<1>

12

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

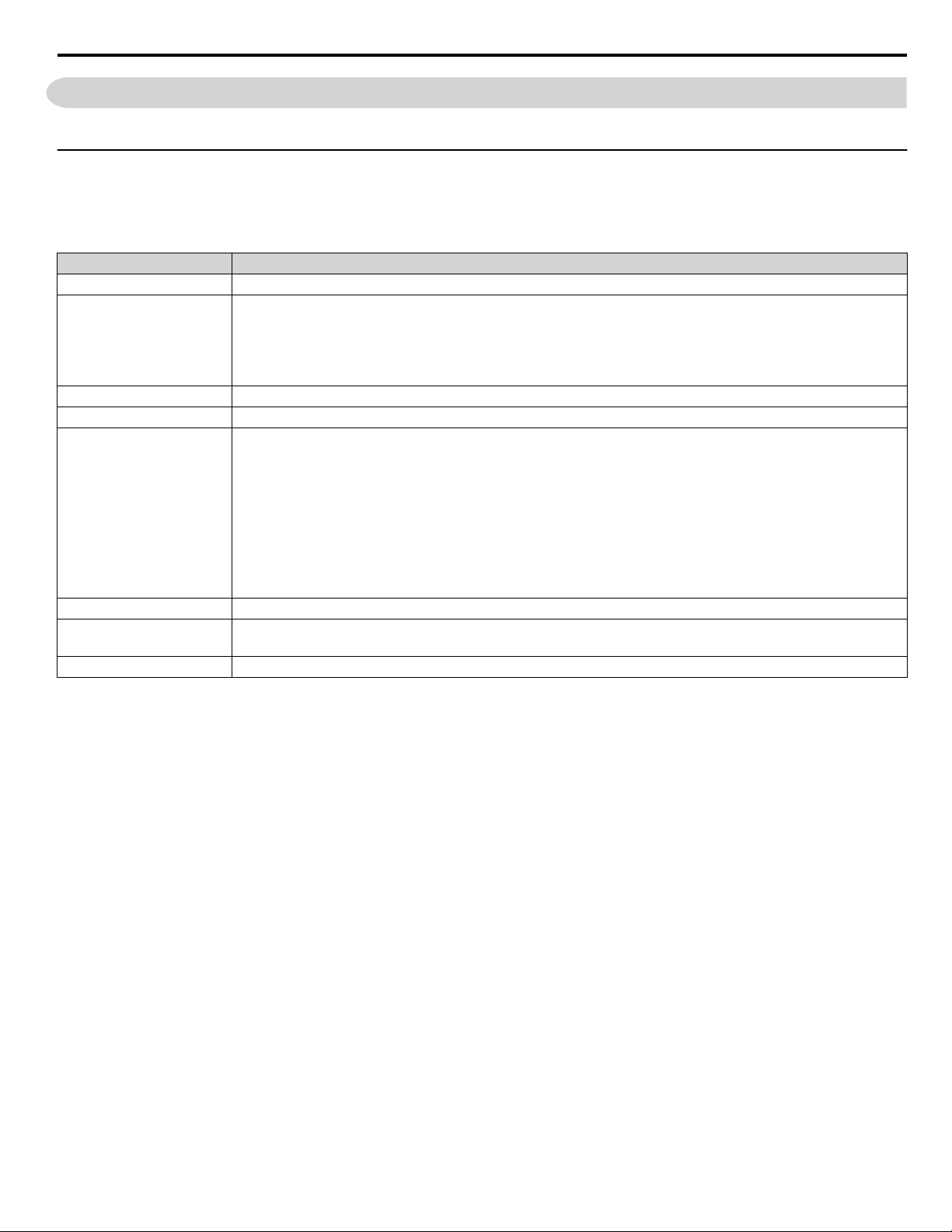

2 Mechanical Installation

2 Mechanical Installation

This section outlines specifications, procedures, and the environment for proper mechanical installation of the drive.

u

Installation Environment

Install the drive in an environment matching the specifications in Table 2 to help prolong the optimum performance life of

the drive.

Table 2 Installation Environment

Environment Conditions

Installation Area Indoors

Flange Type Enclosure: -10 °C to +40 °C (14 °F to 104 °F)

Non-Flange Type Enclosure: -10 °C to +50 °C (14 °F to 122 °F)

Ambient Temperature

Humidity 95% RH or less and free of condensation

Storage Temperature -20 °C to +60 °C

Surrounding Area

Altitude Up to 1000 m without derating, up to 3000 m with output current and voltage derating.

Vibration

Orientation Install the drive vertically to maintain maximum cooling effects.

Drive reliability improves in environments without wide temperature fluctuations.

When using the drive in an enclosure panel, install a cooling fan or air conditioner in the area to ensure that the air

temperature inside the enclosure does not exceed the specified levels.

Do not allow ice to develop on the drive.

Install the drive in an area free from:

• oil mist and dust

• metal shavings, oil, water, or other foreign materials

• radioactive materials

• combustible materials (e.g., wood)

• harmful gases and liquids

• excessive vibration

• chlorides

• direct sunlight.

10 Hz to 20 Hz at 9.8 m/s

20 Hz to 55 Hz at 5.9 m/s2 (Models 4T0058o to 4T0165o) or 2.0 m/s2 (Models 4T0208o to 4T0675o)

2

NOTICE: Avoid placing drive peripheral devices, transformers, or other electronics near the drive as the noise created can lead to erroneous

operation. If such devices must be used in close proximity to the drive, take proper steps to shield the drive from noise.

NOTICE: Damage to Equipment. Drive heatsink air outlet temperature may be over 80 °C. Do not install components above the air outlet

that may be damaged by 80 °C air temperature.

NOTICE: Damage to Equipment. Prevent foreign matter such as metal shavings and wire clippings from falling into the drive during

installation. Failure to comply could result in damage to the drive. Place a temporary cover over the top of the drive during installation.

Remove the temporary cover before drive start-up, as the cover will reduce ventilation and cause the drive to overheat.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

13

Screws

Shipping Package

Attachment

Shipping Package

Attachment

Top Side

Screws

Bottom Side

2 Mechanical Installation

u

Removing the Shipping Package Attachments

Remove the shipping package attachments before installation.

Note: The number of screws varies in accordance with the drive model.

Figure 3 Removing the Shipping Package Attachments

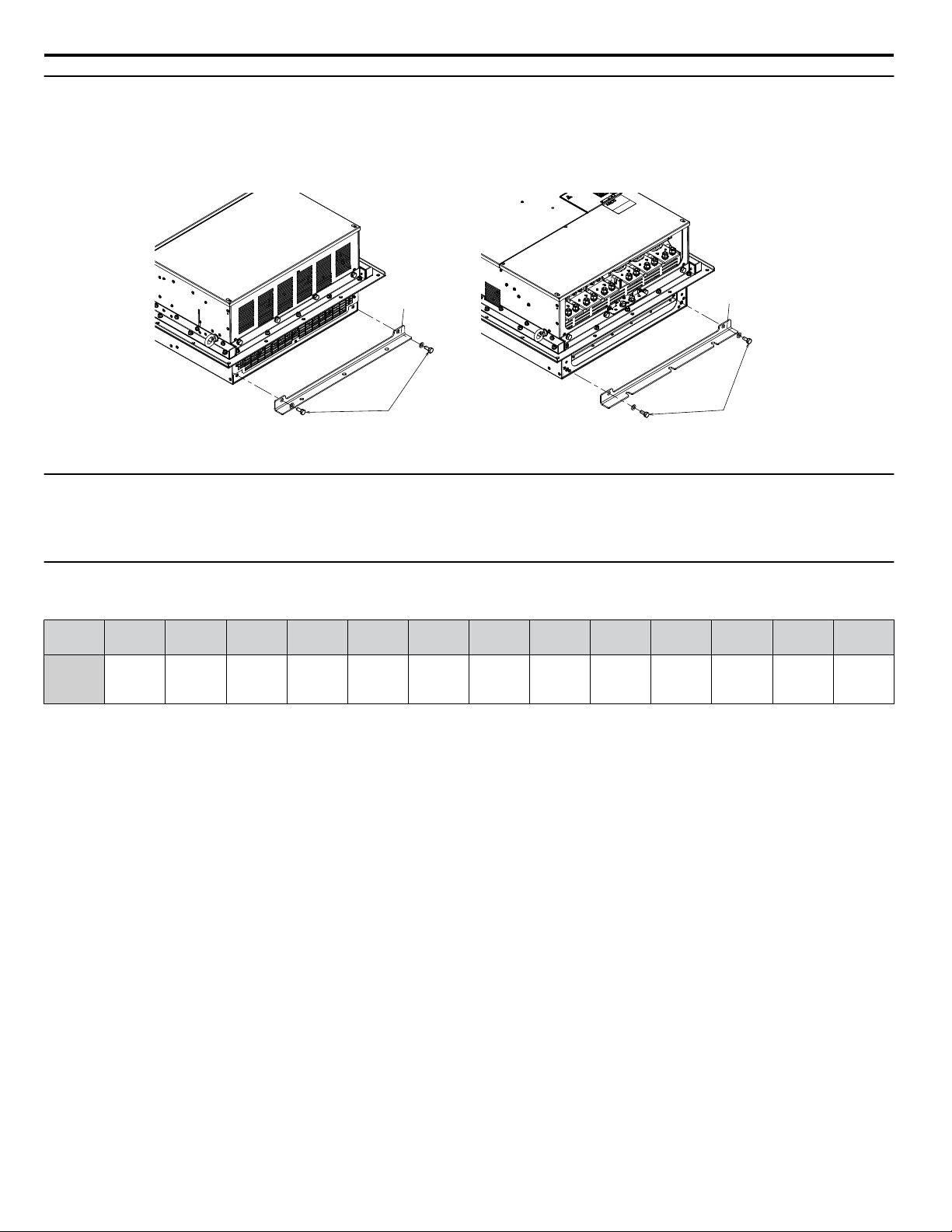

u

Exterior and Mounting Dimensions

Refer to External Mounting and Panel Cutout Dimensions on page 44 for 6-phase/12-pulse exterior and mounting

dimensions.

u

Weights

Table 3 Drive Weights

Drive

Model

Drive

Weight

kg (lb)

4T0058o 4T0072o 4T0088o 4T0103o 4T0139o 4T0165o 4T0208o 4T0250o 4T0296o 4T0362o 4T0414o 4T0515o 4T0675o

21 (46.2) 24 (52.8) 35 (77.0) 35 (77.0) 39 (85.8) 40 (88.2) 78 (172) 90 (198) 95 (209) 97 (214) 127 (280) 210 (463) 215 (474)

14

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

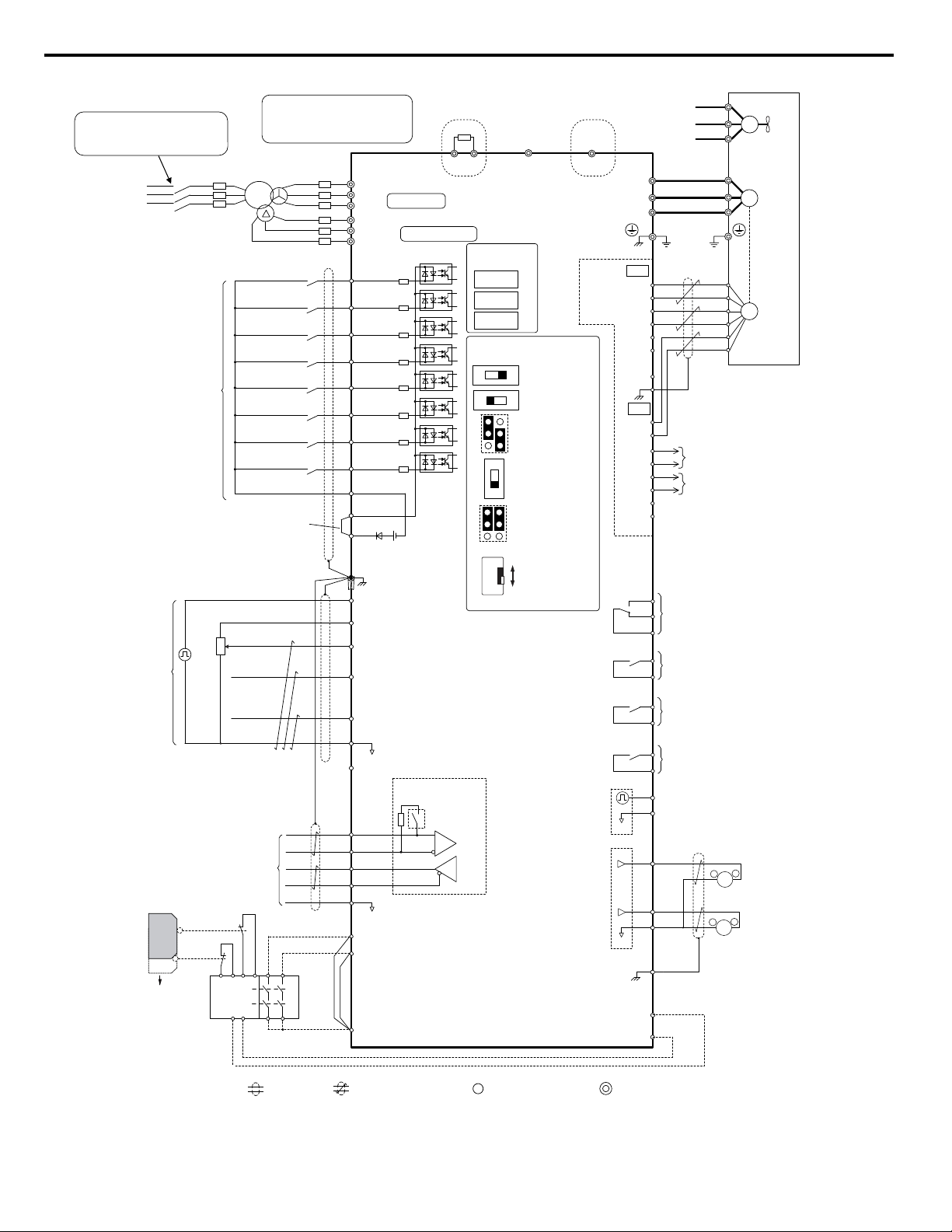

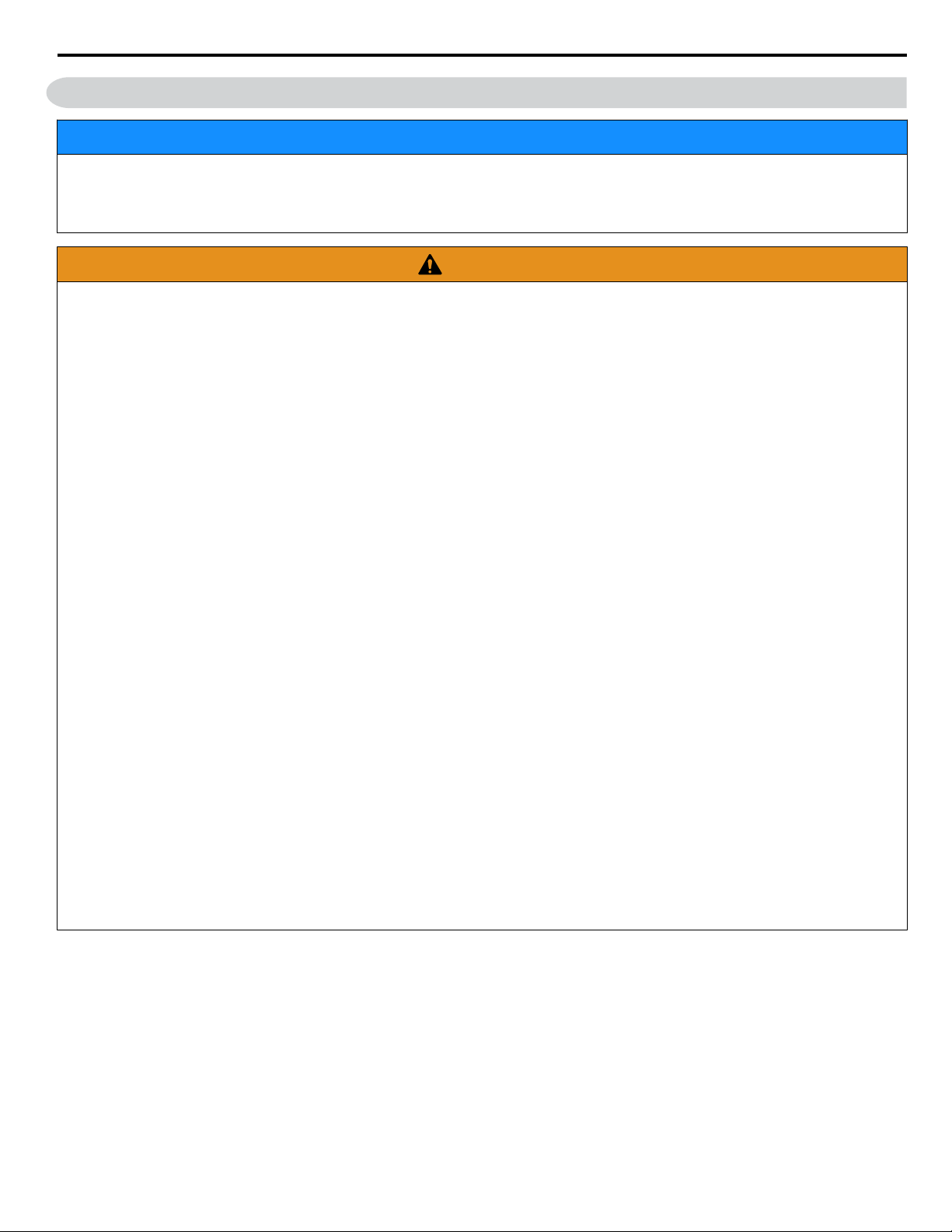

3 Electrical Installation

3 Electrical Installation

u

Standard Connection Diagram

Connect the drive and peripheral devices as shown in Figure 4. It is possible to set and run the drive via the digital operator

without connecting digital I/O wiring.

WARNING! Fire Hazard — Drive Short-Circuit Current Rating. Install adequate branch circuit protection according to applicable local codes

and this manual. Failure to comply could result in fire and damage to the drive or injury to personnel. The device is suitable for use on a

circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 480 Vac maximum (400 V class), when protected by branch

circuit protection devices specified in this manual.

NOTICE: Route motor leads U/T1, V/T2, and W/T3 separate from all other leads to reduce possible interference related issues. Failure to

comply may result in abnormal operation of drive and nearby equipment.

NOTICE: Equipment Hazard. Standard motors used with PWM drives may experience winding failures due to surge voltages when input

line voltage is greater than 480 V or motor wire distance is greater than 100 meters. Select a motor design with insulation tolerant of surge

voltages, such as drive-rated motor for use with PWM drives. Failure to comply could lead to motor winding failure.

Note: The minimum load for the relay outputs M1-M2, M3-M4, M5-M6, and MA-MB-MC is 10 mA.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

15

+

-

+

—

+

+

-

+

—

+

+

-

S1

S2

S3

S4

S5

S6

S7

MP

DM

DM

RP

A1

A2

A3

0 V

AC

R

R

S

S-

IG

H1

H2

HC

Drive

2 k

S8

SC

0 V

0 V

AC

FM

AM

AC

E (G)

S1

S2

<11>

<6>

<12>

<13>

<8>

<10>

<6>

<4>

<3>

+24 V

+V

MA

M1

M2

MB

MC

Forward Run / Stop

Reverse Run / Stop

External fault

Fault reset

Multi-speed step 1

Multi-speed step 2

External Baseblock

Jog speed

Multi-function

digtial inputs

(default setting)

Sink / Source mode

selection wire link

(default: Sink)

CN5-C

CN5-B

CN5-A

Option board

Pulse Train Input

(max 32 kHz)

Shield ground

terminal

Multi-function

analog/pulse

train inputs

Power supply +10.5 Vdc, max. 20 mA

Analog Input 1 (Frequency Reference Bias)

-10 to +10 Vdc (20 k )

Analog Input 2 (Frequency Reference Bias)

-10 to +10 Vdc (20 k )

0 or 4 to 20 mA (250 )

Analog Input 3 / PTC Input (Aux. frequency

reference)

-10 to +10 Vdc (20 k )

—V

Power supply, -10.5 Vdc, max. 20 mA

Safety

switch

MEMOBUS/Modbus comm.

RS-422/RS-485

max. 115.2 kBps

Safe Disable inputs

Wire

jumper

Open

Safety relay /

controller

Termination resistor

(120 , 1/2 W)

DIP

Switch S2

Fault relay output

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function relay output (During Run)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function pulse train output

(Output frequency)

0 to 32 kHz (2.2 k )

Multi-function analog output 1

(Output frequency)

-10 to +10 Vdc (2mA)

or 4 to 20 mA

EDM (Safety Electronic Device Monitor)

Control Circuit

shielded line

twisted-pair shielded line

main circuit terminal

control circuit terminal

M3

M4

Multi-function relay output (Zero Speed)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

M5

M6

Multi-function relay output (Speed Agree 1)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

SP

SN

<9>

AMFM

V

I

V

I

DIP Switch S1

A2 Volt/Curr. Sel

DIP Switch S4

A3 Analog/PTC

Input Sel

PTC

AI

Off

On

DIP Switch S2

Term. Res. On/Off

Jumper S3

H1, H2

Sink/Source Sel.

Jumper S5

AM/FM Volt./Curr.

Selection

Terminal board

jumpers and switches

FM

+

-

AM

<5>

<14>

Ω

Ω

Ω

Ω

Ω

Ω

<13>

Multi-function analog output 2

(Output current)

-10 to +10 Vdc (2mA)

or 4 to 20 mA

<15>

<6>

A+

A-

B-

Z-

B+

Z+

a+

ab+

bz+

z-

FE

IP

IG

TB1

SD

TB2

B track monitor

A track monitor

M

U/T1

V/T2

W/T

U

FU

FV

FW

V

W

3

Ground

Cooling fan

PG

M

PG- X3

connectors

(option)

Ω

Slide Switch S6

DM+, DMN.C./N.O. Selection

N.C.

N.O.

<7>

Terminals B1, B2, -, and +3, B1

are for power option connections.

Never connect power supply lines

to these terminals

B1 B2

Fuse

Main Circuit

Three-Phase

Power Supply

380 to 480 V

50/60 Hz

Wiring sequence should shut off

power to the drive when a fault

output is triggered.

BCP

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

R

S

T

Main

Switch

Models 4T0058 and 4T0072

Dynamic braking resistor

(option) <1> <2>

U1

V1

W1

W2

V2

U2

—

+3

Models 4T0088 to 4T0675

CDBR dynamic braking unit

(option) <1> <2>

<16>

<17>

3 Electrical Installation

Figure 4 Drive Standard Connection Diagram

16

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

3 Electrical Installation

<1> Set up a thermal relay sequence to disconnect drive main power in the event of an overheat condition on the dynamic

braking option.

<2> Set L8-55 to 0 to disable the protection function of the built-in braking transistor of the drive when using an optional

regenerative converter or dynamic braking option. Leaving L8-55 enabled may cause a braking resistor fault (rF). Additionally,

disable Stall Prevention (L3-04 = 0) when using an optional regenerative converter, regenerative or braking units, or dynamic

braking option. Leaving If L3-04 enabled may prevent the drive from stopping within the specified deceleration time.

<3> Supplying power to the control circuit separately from the main circuit requires 24 V power supply (option).

<4> This figure illustrates an example of a sequence input to S1 through S8 using a non-powered relay or an NPN transistor.

Install the wire link between terminals SC-SP for Sink mode, between SC-SN for Source mode, or leave the link out for

external power supply. Never short terminals SP and SN, as it will damage the drive.

<5> This voltage source supplies a maximum current of 150 mA when not using a digital input card DI-A3.

<6> The maximum output current capacity for the +V and -V terminals on the control circuit is 20 mA. Never short terminals

+V, -V, and AC, as it can cause erroneous operation or damage the drive.

<7> Slide switch S6 selects N.C. or N.O. as the state of the DM+ and DM- terminals for EDM output. Slide switch S6 is

available on terminal board ETC74030o.

<8> Set DIP switch S1 to select between a voltage or current input signal to terminal A2. The default setting is for current

input.

<9> Set DIP switch S4 to select between analog or PTC input for terminal A3.

<10> Set DIP switch S2 to the ON position to enable the termination resistor in the last drive in a MEMOBUS/Modbus network.

<11> Use jumper S3 to select between Sink mode, Source mode, and external power supply for the Safe Disable inputs.

<12> Disconnect the wire jumper between H1 — HC and H2 — HC when utilizing the Safe Disable input.

<13> Monitor outputs work with devices such as analog frequency meters, ammeters, voltmeters, and wattmeters. They are

not intended for use as a feedback-type signal.

<14> Use jumper S5 to select between voltage or current output signals at terminals AM and FM. Set parameters H4-07 and

H4-08 accordingly.

<15> Self-cooling motors do not require the same wiring necessary for motors with cooling fans.

<16> Refer to local codes for proper branch circuit protection (BCP) on the primary side of the 6-Phase/12-Pulse transformer.

<17> Fuse selection for the secondary side is of the 6-Phase/12-Pulse transformer is shown in Table 13 and Table 14.

WARNING! Sudden Movement Hazard. Do not close the wiring for the control circuit unless the multifunction input terminal parameters are

properly set. Improper sequencing of run/stop circuitry could result in death or serious injury from moving equipment.

WARNING! Sudden Movement Hazard. Ensure start/stop and safety circuits are wired properly and in the correct state before energizing

the drive. Failure to comply could result in death or serious injury from moving equipment. When programmed for 3-Wire control, a momentary

closure on terminal S1 may cause the drive to start.

WARNING! Sudden Movement Hazard. When using a 3-Wire sequence, set the drive to 3-Wire sequence prior to wiring the control terminals

and set parameter b1-17 to 0 so the drive will not accept a Run command at power up (default). If the drive is wired for a 3-Wire sequence

but set up for a 2-Wire sequence (default), and parameter b1-17 is set to 1 so the drive accepts a Run command at power up, the motor

will rotate in reverse direction at drive power up and may cause injury.

WARNING! Sudden Movement Hazard. Confirm the drive I/O signals and external sequence before executing the application preset

function. Executing the application preset function or setting A1-06 ≠ 0 will change the drive I/O terminal functions and may cause unexpected

equipment operation. Failure to comply may cause death or serious injury.

NOTICE: When using the automatic fault restart function with wiring designed to shut off the power supply upon drive fault, make sure the

drive does not trigger a fault output during fault restart (L5-02 = 0, default). Failure to comply will prevent the automatic fault restart function

from working properly.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

17

R1/L11

S1/L21

T1/L31

Gate

Board

Control

Board

Operator

B1

R/L1

S/L2

T/L3

–

U/T1

V/T2

W/T3

Relay

Current

Sensor

B2

Gate

Board

Control

Board

Operator

+3

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

–

U/T1

V/T2

W/T3

Relay

Current

Sensor

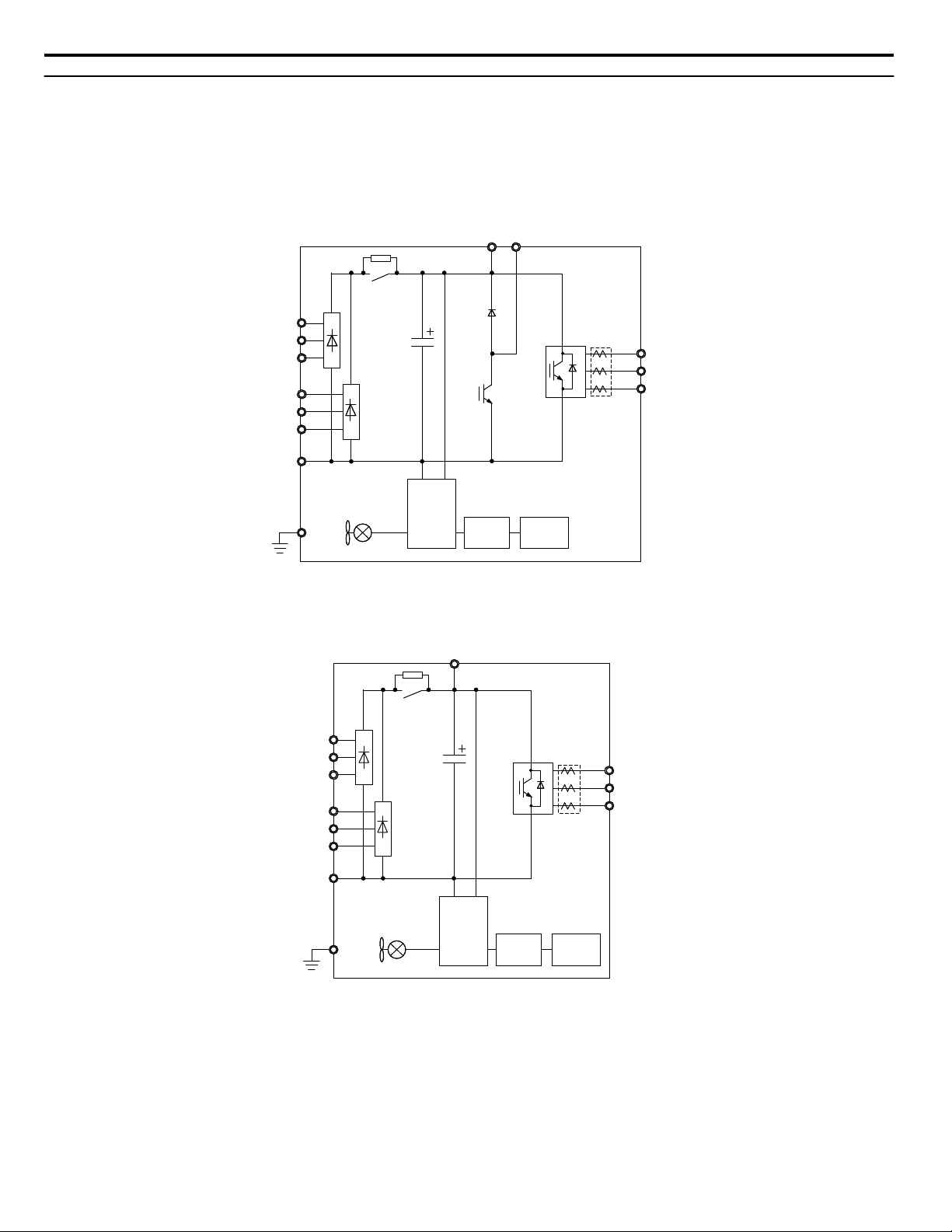

3 Electrical Installation

u

Main Circuit Connection Diagram

Refer to Figure 5, Figure 6, and Figure 7 when wiring the main circuit of the drive. Connections may vary based on drive

capacity.

NOTICE: Do not use the negative DC bus terminal “⊖” as a ground terminal. This terminal is at high DC voltage potential. Improper wiring

connections could damage the drive.

6-Phase/12-Pulse Input 400 V Class Models 4T0058o and 4T0072o

n

Figure 5 Connecting Main Circuit Terminals

6-Phase/12-Pulse Input 400 V Class Models 4T0088o to 4T0139o

n

Figure 6 Connecting Main Circuit Terminals

18

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

Gate

Board

Control

Board

Operator

24 V

Power

Supply

+3

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

ー

U/T1

V/T2

W/T3

Relay

Current

Sensor

+

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

CDBR dynamic braking unit

(option) <2>

Dynamic braking resistor

(option) <1>

Motor

+3

-

Main Circuit

Power Supply

6-Phase/12-Pulse

Isolation Transformer

3-Phase Line Monitor

FuseBCP

Fuse

<3>

<4>

3 Electrical Installation

6-Phase/12-Pulse Input 400 V Class Models 4T0165o to 4T0675o

n

Figure 7 Connecting Main Circuit Terminals

6-Phase/12-Pulse Rectification

n

Installing a Transformer

Install a 6-Phase/12-Pulse isolation transformer with output windings phase-shifted by 30 electrical degrees or install a Hybrid

6-Phase topology on the power supply.

Installing a 3-Phase Line Monitor

Yaskawa requires installation of a 3-Phase line monitor to protect the drive in the event of an input line phase loss.

The 3-Phase line monitor must be installed on the primary circuit of the 6-Phase/12-Pulse transformer and connected to the

drive to remove the Run command when a phase loss condition occurs.

The drive power circuit may be damaged during a phase-loss condition if a 3-Phase line monitor is not properly installed.

Contact a Yaskawa representative for help selecting the optimum 3-Phase line monitor and fuses.

Connection Diagram

Figure 8 Main Circuit Terminal Connections

<1> A dynamic braking resistor can be connected to the B1 and B2 terminals on models 4T0058o and 4T0072o.

<2> A CDBR dynamic braking unit cannot be connected to models 4T0058o or 4T0072o.

<3> Refer to local codes for proper branch circuit protection (BCP) on the primary side of the 6-Phase/12-Pulse transformer.

<4> Fuse selection for the secondary side is of the 6-Phase/12-Pulse transformer is shown in Table 13 and Table 14

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

19

S1/L21

R1/L11

T1/L31

T/L3

U/T1

R/L1

S/L2

V/T2

W/T3

B1 B2

3

R/L1 S/L2 T/L3 R1/L11 S1/L21 T1/L31 U/T1 V/T2 W/T3

R/L1

S/L2

T/L3

R1/L11

U/T1 W/T3V/T2

S1/L21

T1/L31

3

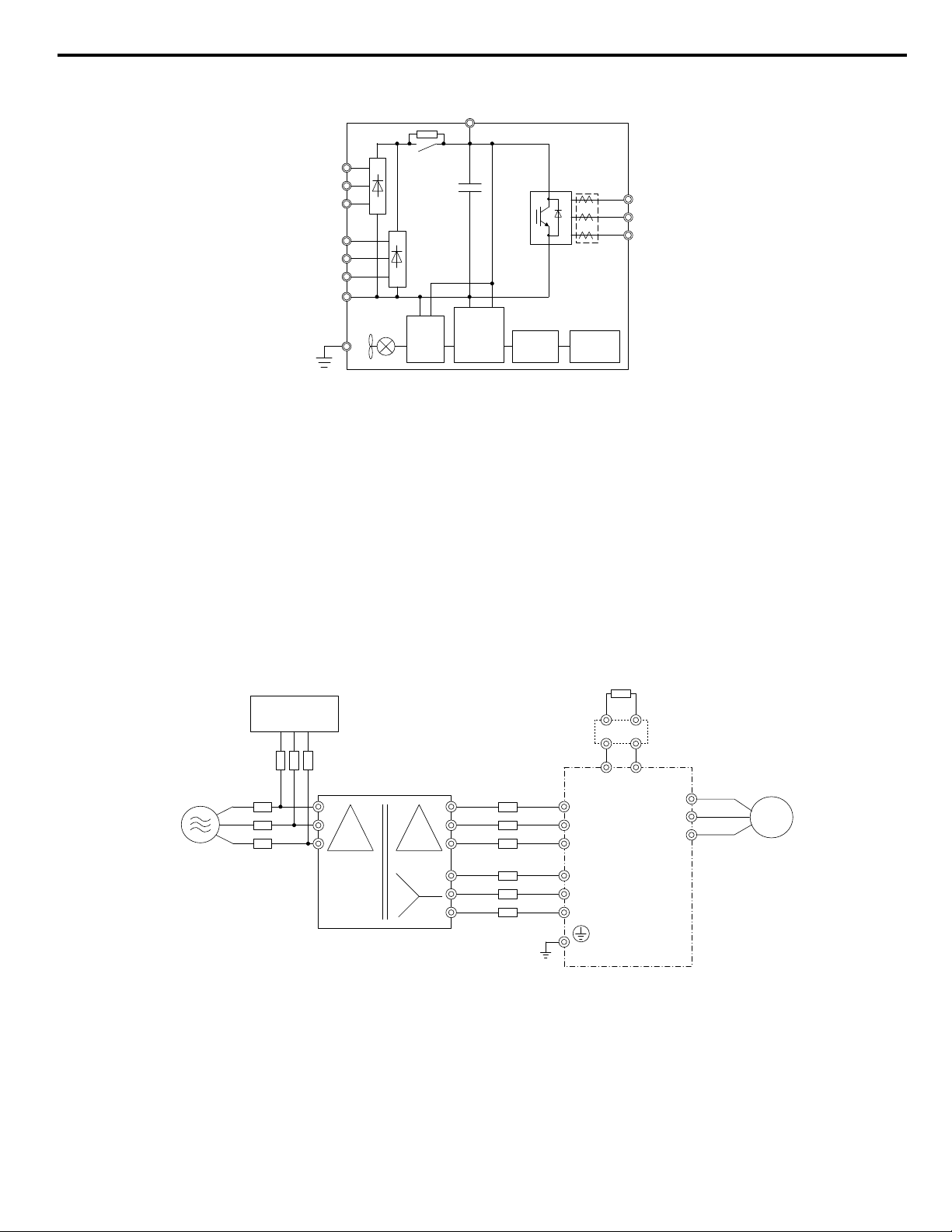

3 Electrical Installation

u

Terminal Specifications

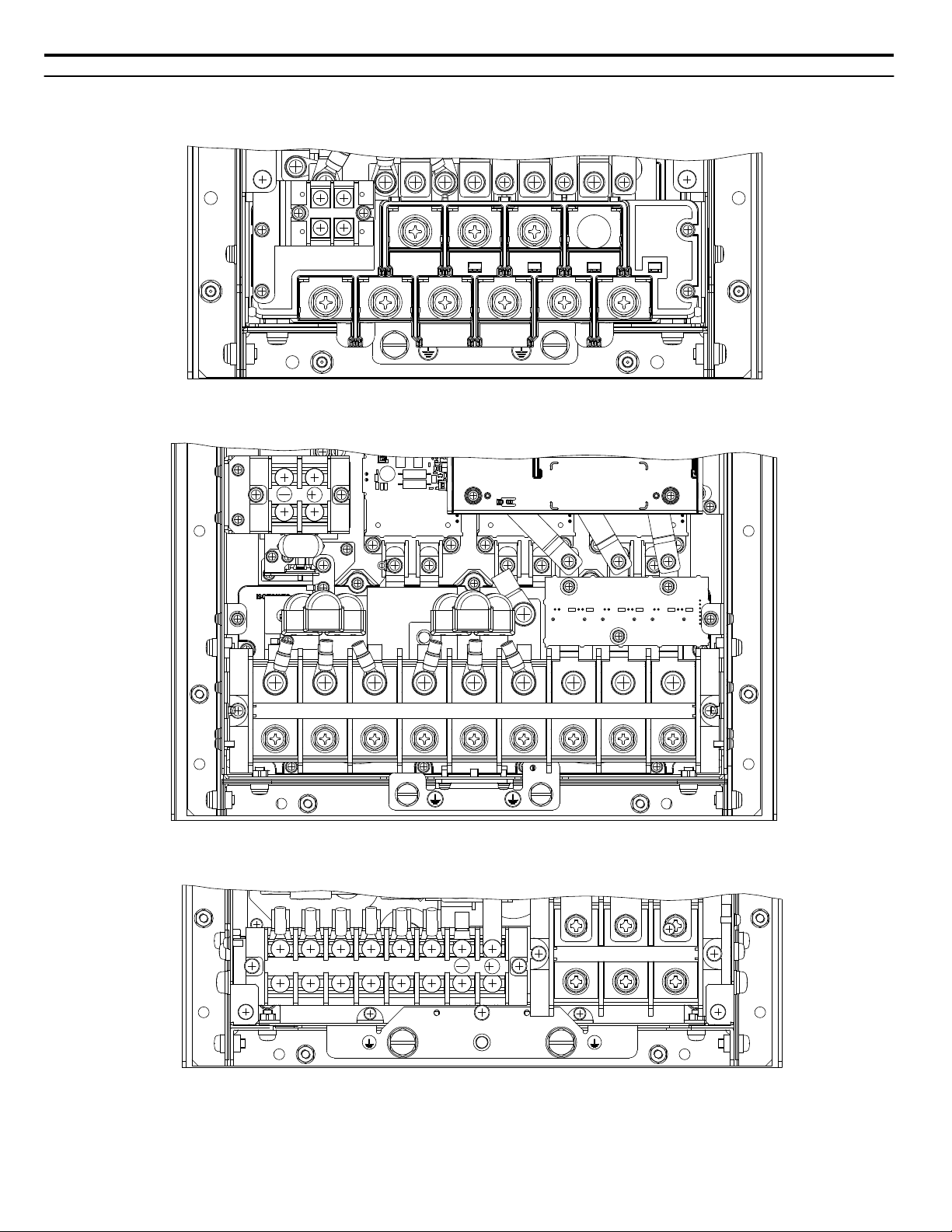

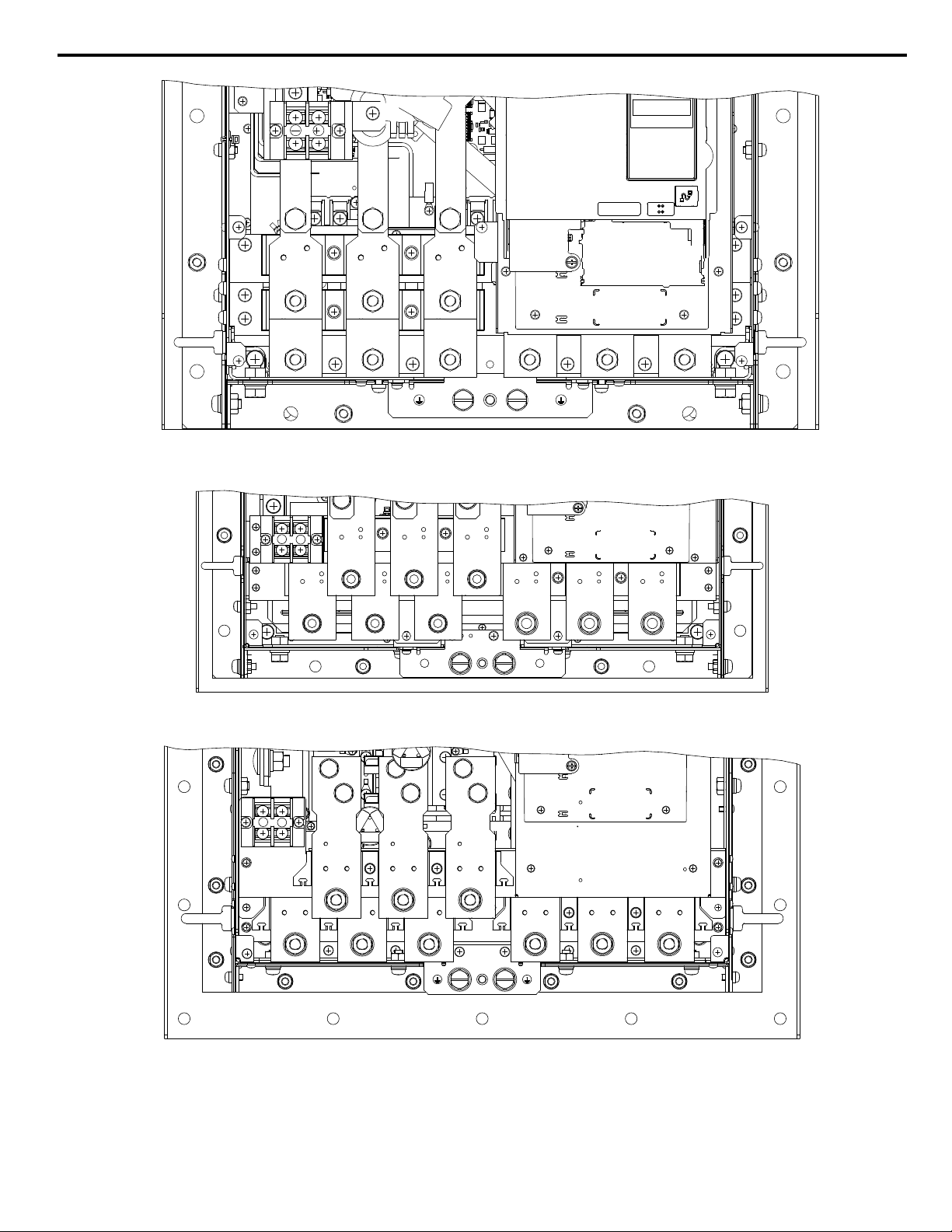

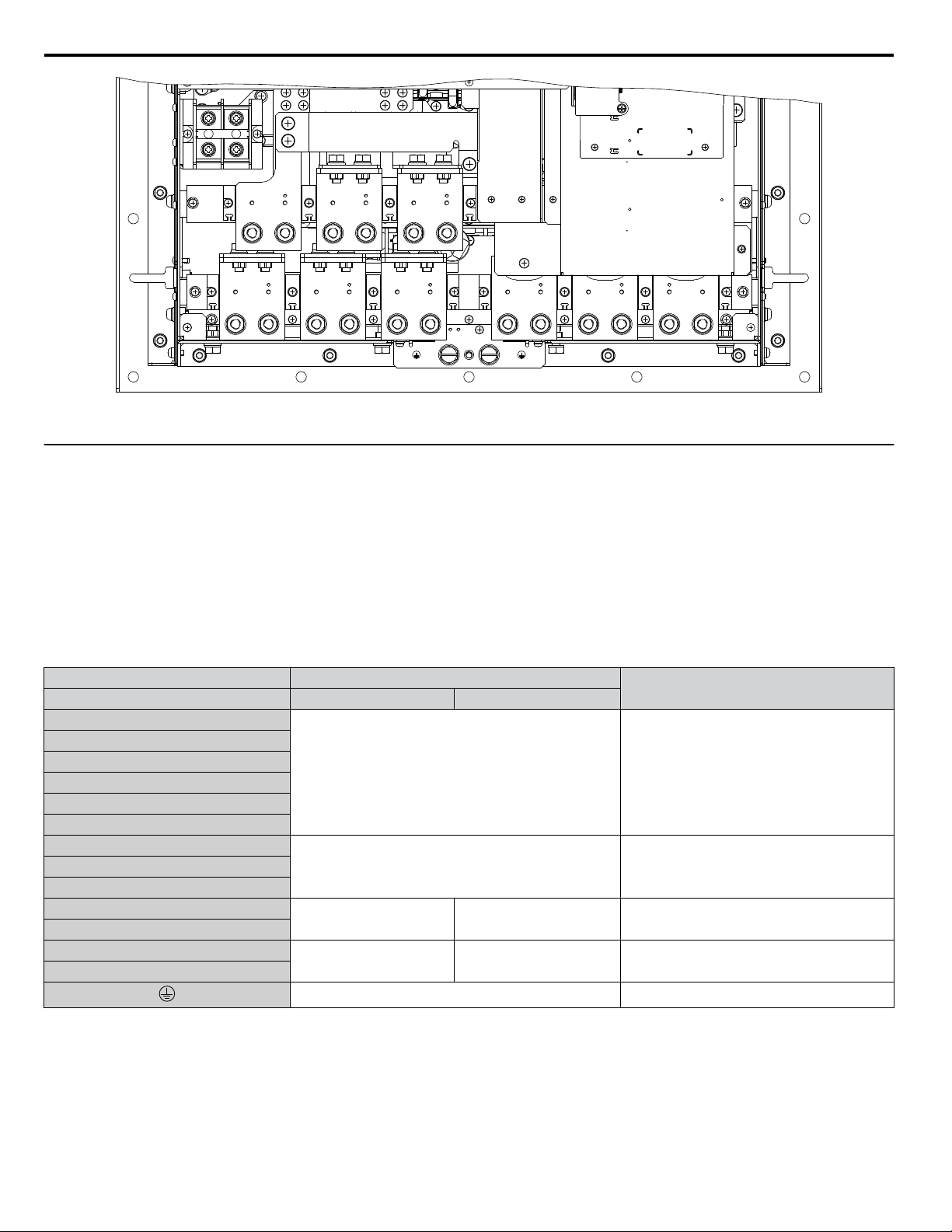

Figure 9 to Figure 15 show the different terminal arrangements for the drive capacities.

Figure 9 Model 4T0058o and 4T0072o Terminals

20

Figure 10 Models 4T0088o and 4T0103o Terminals

Figure 11 Models 4T0139o and 4T0165o Terminals

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

R1/L11

S1/L21

T1/L31

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

3

Figure 12 Model 4T0208o Terminals

R1/L11

S1/L21

T1/L31

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

+3

-

R1/L11

S1/L21

T1/L31

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

+3

-

3 Electrical Installation

Figure 13 Models 4T0250o to 4T0362o Terminals

Figure 14 Model 4T0414o Terminals

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

21

R1/L11

S1/L21

T1/L31

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

+3

-

3 Electrical Installation

Figure 15 Models 4T0515o and 4T0675o Terminals

u

Main Circuit Wiring

This section describes the functions, specifications, and procedures required to safely and properly wire the main circuit in

the drive.

NOTICE: Do not solder the ends of wire connections to the drive. Soldered wiring connections can loosen over time. Improper wiring practices

could result in drive malfunction due to loose terminal connections.

NOTICE: Do not switch the drive input to start or stop the motor. Frequently switching the drive on and off shortens the life of the DC bus

charge circuit and the DC bus capacitors, and can cause premature drive failures. For the full performance life, refrain from switching the

drive on and off more than once every 30 minutes.

Main Circuit Terminal Functions

n

Table 4 Main Circuit Terminal Functions

Terminal Type

Model

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

U/T1

W/T3

B1

B2

⊖

⊕3

Note: Note: DC power supply input is not available for 6-Phase/12-Pulse Input models.

Main Circuit Fuses

n

4T0058o and 4T0072o 4T0088o to 4T0675o

Main circuit power supply input Not available Connects line power to the drive

Drive output Connects to the motorV/T2

Braking resistor Not available

Not available

10 Ω or less Grounding terminal

Braking unit connection

(⊕3 and ⊖)

Available for connecting a braking resistor or a

braking resistor unit option

Only for connecting dynamic braking options

Function

The 6-Phase/12-Pulse drive requires fuses to be installed on each of the 6 input phases between the 6-Phase/12- Pulse

transformer and the drive. Select fuses from Table 13 or Table 14 according to drive model to maintain standards compliance.

22

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

3 Electrical Installation

u

Wire Gauges and Tightening Torques

Use the tables in this section to select the appropriate wires and crimp terminals.

Gauges listed in the tables are for use in the United States.

Note: 1. Wire gauge recommendations based on drive continuous current ratings (ND) using 75 °C 600 Vac vinyl-sheathed wire assuming ambient

temperature within 40 °C and wiring distance shorter than 100 m.

2. Terminals ⊕3 and ⊖ are for connecting optional power devices. Use caution to connect only approved devices to the correct terminal(s).

• Consider the amount of voltage drop when selecting wire gauges. Increase the wire gauge when the voltage drop is greater

than 2% of motor rated voltage. Ensure the wire gauge is suitable for the terminal block. Use the following formula to

calculate the amount of voltage drop:

Line drop voltage (V) = 3 × wire resistance (Ω/km) × wire length (m) × current (A) × 10

-3

• Refer to CDBR manual TOBP C720600 00/TOBP C720600 01 for dynamic braking wire gauges.

• Use terminals ⊕3 and ⊖ when connecting a CDBR dynamic braking unit.

• Do not connect a regenerative converter or a regenerative unit to the 6-Phase/12-Pulse drive.

• Refer to UL Standards on page 84 for information on UL compliance.

Yaskawa recommends using closed-loop crimp terminals on all drive models. UL/cUL approval requires the use of closedloop crimp terminals when wiring the drive main circuit terminals. Use only the tools recommended by the terminal

manufacturer for crimping. Refer to Closed-Loop Crimp Terminal Size on page 86 for closed-loop crimp terminal

recommendations.

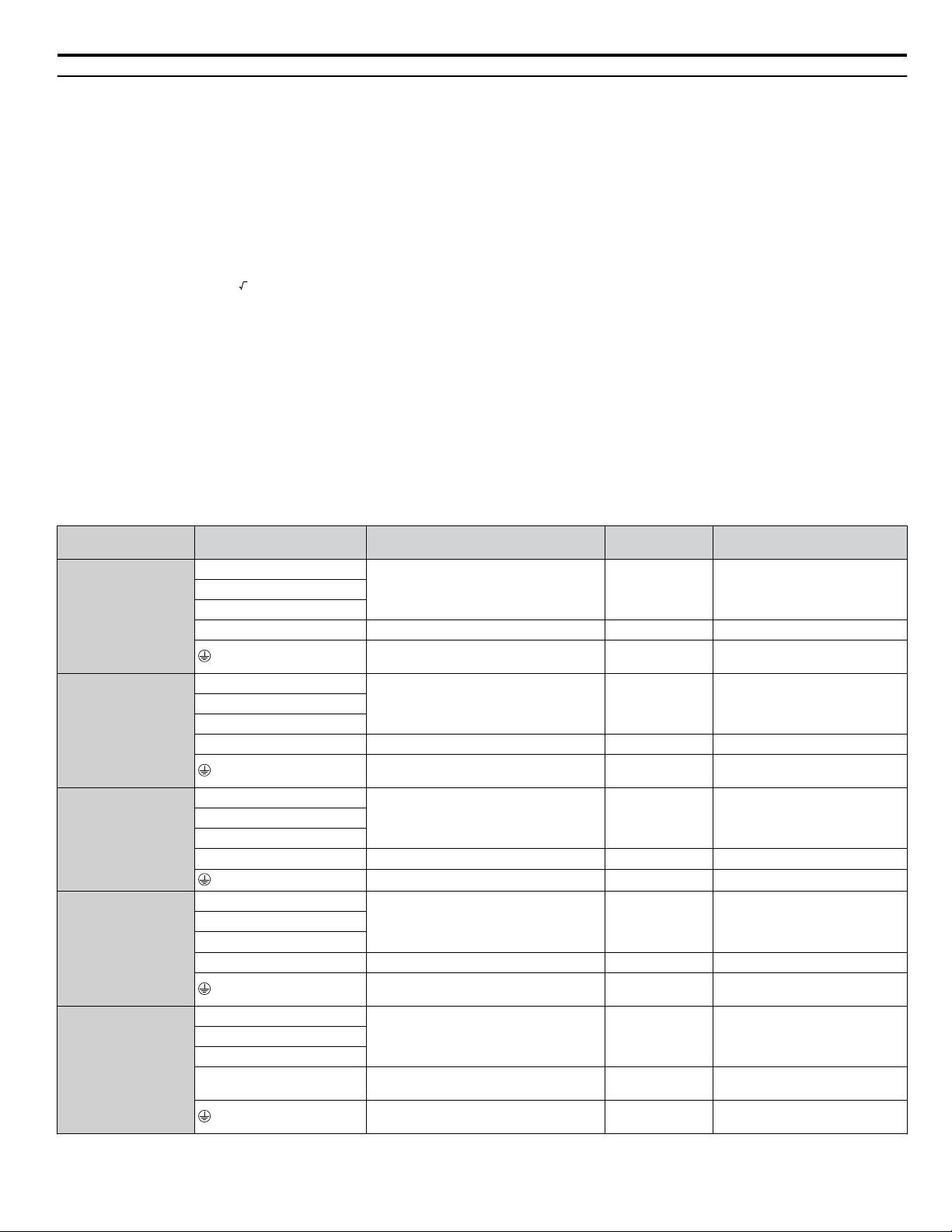

The wire gauges listed in Table 5 are Yaskawa recommendations and are based on the 6-Phase input current ratings specified

in Table 14. Refer to local codes for proper wire gauge selections.

Drive Model

4T0058o

4T0072o

4T0088o

4T0103o

4T0139o

4T0165o

4T0208o

Table 5 Wire Gauge and Torque Specifications

Terminal

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

B1, B2 22 to 10 (0.3 to 5.3) M4 1.2 (10.6)

Refer to applicable codes for wire size M8

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

B1, B2 22 to 10 (0.3 to 5.3) M4 1.2 (10.6)

Refer to applicable codes for wire size M8

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

⊖, ⊕3

Refer to applicable codes for wire size M8 9 to 11 (79.7 to 97.4)

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

⊖, ⊕3

U/T1, V/T2, W/T3 6 to 250 (13.3 to 127) M8 15.0 (132.8)

Refer to applicable codes for wire size M10

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

⊖, ⊕3

Refer to applicable codes for wire size M10

Refer to applicable codes for wire size M10

Wire Range

AWG, kcmil

10 to 1/0 (5.3 to 53.5) M8

10 to 3/0 (5.3 to 85.0) M8

6 to 250 (13.3 to 127) M8 9 to 11 (79.7 to 97.4)R1/L11, S1/L21, T1/L31

22 to 1/0 (0.3 to 53.5) M6 2.5 to 3.0 (22.1 to 26.6)

22 to 1/0 (0.3 to 53.5) M6

22 to 1/0 (0.3 to 53.5) M6

Screw

Size

Tightening Torque

N·m (lb.in.)

9 to 11

(79.7 to 97.4)

9 to 11

(79.7 to 97.4)

9 to 11

(79.7 to 97.4)

9 to 11

(79.7 to 97.4)

2.5 to 3.0

(22 to 1/0)

18 to 23

(159.3 to 203.6)

18 to 23

(159.3 to 203.6)

2.5 to 3.0

(22.1 to 26.6)

18 to 23

(159.3 to 203.6)

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

23

3 Electrical Installation

Drive Model Terminal

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

4T0250o

⊖, ⊕3

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/3 M12

4T0296o

⊖, ⊕3

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3 M12

4T0362o

⊖, ⊕3

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

4T0414o

⊖, ⊕3

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

4T0515o

⊖, ⊕3

R/L1, S/L2, T/L3

R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

4T0675o

⊖, ⊕3

Wire Range

AWG, kcmil

Refer to applicable codes for wire size M10

22 to 1/0 (0.3 to 53.5) M6

Refer to applicable codes for wire size M10

Refer to applicable codes for wire size

22 to 1/0 (0.3 to 53.5) M6

Refer to applicable codes for wire size M12

Refer to applicable codes for wire size

22 to 1/0 (0.3 to 53.5) M6

Refer to applicable codes for wire size M12

Refer to applicable codes for wire size M12

22 to 1/0 (0.3 to 53.5) M6

Refer to applicable codes for wire size M12

Refer to applicable codes for wire size M12

13.3 to 127 (6 to 250) M8

Refer to applicable codes for wire size M12

Refer to applicable codes for wire size M12

13.3 to 127 (6 to 250) M8

Refer to applicable codes for wire size M12

Screw

Size

M10

M10

Tightening Torque

N·m (lb.in.)

18 to 23

(159.3 to 203.6)

2.5 to 3.0

(22.1 to 26.6)

18 to 23

(159.3 to 203.6)

18 to 23

(159.3 to 203.6)

32 to 40

(283.2 to 354.0)

2.5 to 3.0

(22.1 to 26.6)

32 to 40

(283.2 to 354.0)

18 to 23

(159.3 to 203.6)

32 to 40

(283.2 to 354.0)

2.5 to 3.0

(22.1 to 26.6)

32 to 40

(283.2 to 354.0)

32 to 40

(283.2 to 354.0)

2.5 to 3.0

(22.1 to 26.6)

32 to 40

(283.2 to 354.0)

32 to 40

(283.2 to 354.0)

13.5 to 15

(119.5 to 132.8)

32 to 40

(283.2 to 354.0)

32 to 40

(283.2 to 354.0)

13.5 to 15

(119.5 to 132.8)

32 to 40

(283.2 to 354.0)

u

Wiring Checklist

No.

1 Check drive model number to ensure receipt of correct model. 10

2 Make sure you have the correct braking resistors, DC link chokes, noise filters, and other peripheral devices.

3 Check the option card model number.

4 Ensure that the area surrounding the drive complies with specifications. 13

24

Item Page(s)

Drive, Peripherals, Option Cards

Installation Area and Physical Setup

Power Supply Voltage, Output Voltage

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

3 Electrical Installation

No. Item Page(s)

5 The voltage from the power supply should be within the input voltage specification range of the drive. –

6 The voltage rating for the motor should match the drive output specifications.

7 Verify that the drive is properly sized to run the motor.

Main Circuit Wiring

8 Confirm proper branch circuit protection as specified by national and local codes. 15

Properly wire the power supply to drive terminals R/L1, S/L2, T/L3, R1/L11, S1/L21, and T1/L31.

9

Note: Confirm that a 6-Phase/12-Pulse isolation transformer with each of the output windings phase-shifted

by 30 electrical degrees or a Hybrid 6-Phase topology is installed on the power supply.

Properly wire the drive and motor together.

10

The motor lines and drive output terminals U/T1, V/T2, and W/T3 should match in order to produce the desired phase

order. If the phase order is incorrect, the drive will rotate in the opposite direction.

11 Use 600 Vac vinyl-sheathed wire for the power supply and motor lines. 23

Use the correct wire gauges for the main circuit.

• Consider the amount of voltage drop when selecting wire gauges. Increase the wire gauge when the voltage drop is

12

greater than 2% of motor rated voltage. Ensure the wire gauge is suitable for the terminal block. Use the following

formula to calculate the amount of voltage drop:

Line drop voltage (V) = 3 × wire resistance (Ω/km) × wire length (m) × current (A) × 10

-3

• If the cable between the drive and motor exceeds 50 m, adjust the carrier frequency set to C6-02 accordingly.

13 Properly ground the drive. –

14 Tighten control circuit and grounding terminal screws. 23

Set up overload protection circuits when running multiple motors from a single drive.

Power supply

15

Drive

MC1

MC2

MCn

OL1

OL2

OLn

M1

M2

Mn

MC1 — MCn

OL 1 — OLn

… magnetic contactor

… thermal relay

10

18

–

23

–

Note: Close MC1 – MCn before operating the drive. MC1 – MCn cannot be switched off during run.

Install a magnetic contactor when using a dynamic braking option. Properly install the resistor and ensure that overload

16

protection shuts off the power supply using the magnetic contactor.

17 Verify phase advancing capacitors, input noise filters, or GFCIs are NOT installed on the output side of the drive. –

Control Circuit Wiring

18 Use twisted-pair line for all drive control circuit wiring. –

19

Ground the shields of shielded wiring to the GND terminal.

20 For 3-Wire sequence, set parameters for multi-function contact input terminals S1 – S8, and wire control circuits. –

21 Properly wire any option cards. –

22 Check for any other wiring mistakes. Only use a multimeter to check wiring. –

23 Properly fasten drive control circuit terminal screws. 23

24 Pick up all wire clippings. –

25 Ensure that no frayed wires on the terminal block are touching other terminals or connections. –

26 Properly separate control circuit wiring and main circuit wiring. –

27 Analog signal line wiring should not exceed 50 m. –

28 Safe Disable input wiring should not exceed 30 m. –

–

–

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

25

4 Start-Up Programming & Operation

4 Start-Up Programming & Operation

u

Powering Up the Drive

Review the following checklist before applying power.

Item to Check Description

6-Phase/12-Pulse Isolated 380 to 480 Vac 50/60 Hz, 30 electrical degrees phase-shifted each phase

Power supply

Drive output terminals and

motor terminals

Control circuit terminals Check control circuit terminal connections.

Drive control terminal status Open all control circuit terminals (off).

Status of the load and connected

machinery

<1> Install a 6-Phase/12-Pulse isolation transformer with each of the output windings phase-shifted by 30 electrical degrees or use a Hybrid 6-Phase

topology.

Properly wire the power supply input terminals (R/L1, S/L2, T/L3, R1/L11, S1/L21, T1/L31).

Check for proper grounding of drive and motor.

Properly wire drive output terminals U/T1, V/T2, and W/T3 with motor terminals U, V, and W.

Decouple the motor from the load.

<1>

26

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

5 Troubleshooting

5 Troubleshooting

NOTICE

Refer to the A1000 Technical Manual SIEP C710616 41 for information on Troubleshooting and complete product

instructions necessary for proper installation, set-up, troubleshooting and maintenance.

The A1000 Technical Manual is posted on the Yaskawa website, www.yaskawa.com.

WARNING

Electrical Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply could result in death or serious injury.

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50 Vdc. To prevent electric shock,

wait for at least the time specified on the warning label; after all indicators are OFF, measure for unsafe voltages to confirm

the drive is safe prior to servicing.

Do not operate equipment with covers removed.

Failure to comply could result in death or serious injury.

The diagrams in this section may illustrate drives without covers or safety shields to display details. Be sure to reinstall covers

or shields before operating the drives and run the drives according to the instructions described in this manual.

Do not touch terminals before the capacitors have fully discharged.

Failure to comply could result in death or serious injury.

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50 Vdc. To prevent electric shock,

wait for at least the time specified on the warning label; after all indicators are OFF, measure for unsafe voltages to confirm

the drive is safe prior to servicing.

After blowing a fuse or tripping a GFCI, do not attempt to restart the drive or operate peripheral devices until five

minutes pass and CHARGE lamp is OFF.

Failure to comply could result in death, serious injury, and damage to the drive.

Check wiring and peripheral device ratings to identify the cause of trips.

Contact your supplier if the cause cannot be identified.

Installation, maintenance, inspection and servicing must be performed only by authorized personnel familiar with installation,

adjustment and maintenance of AC drives.

Do not perform work on the drive while wearing loose clothing, jewelry, or without eye protection.

Failure to comply could result in death or serious injury.

Do not remove covers or touch circuit boards while the power is on.

Failure to comply could result in death or serious injury.

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

27

LO

RE

F2F1

ESC

RUN STOP

ENTERRESET

RESET

— MODE —

oC

Overcurrent

DRV

FWD

RESET

ALM

5 Troubleshooting

u

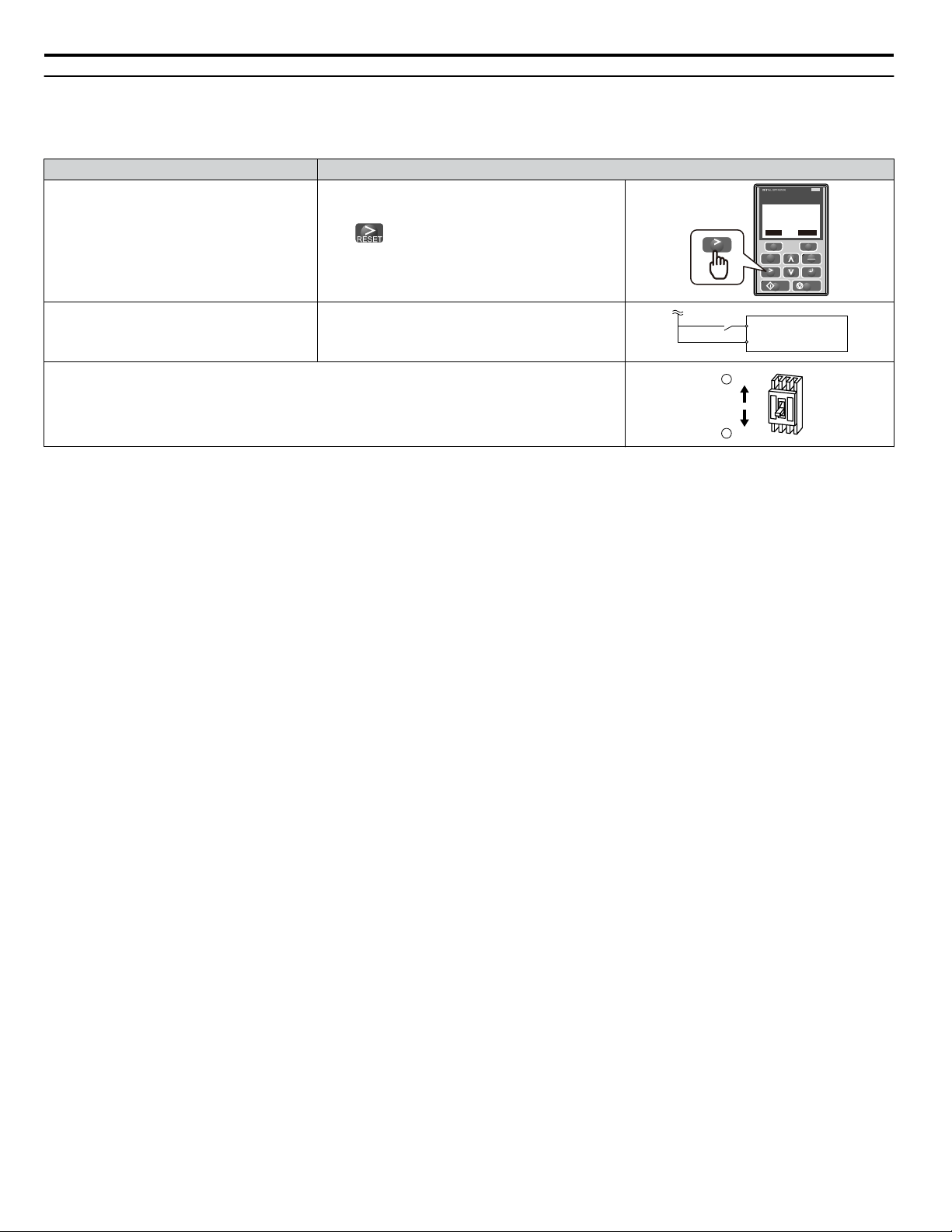

Fault Reset Methods

When a fault occurs, the cause of the fault must be removed and the drive must be restarted. The table below lists the different

ways to restart the drive.

After the Fault Occurs Procedure

Fix the cause of the fault, restart the drive, and

reset the fault

Resetting via Fault Reset Digital Input S4

Press on the digital operator when the error code

is displayed.

Close then open the fault signal digital input via

terminal S4. S4 is set for “Fault Reset” as default

(H1-04 = 14).

Fault Reset Switch

2

Drive

S4 Fault Reset Digital Input

SC Digital Input Common

ON

Turn off the main power supply if the above methods do not reset the fault. Reapply power after the

digital operator display has turned off.

1

OFF

Note: If the Run command is present, the drive will disregard any attempts to reset the fault. Remove the Run command before attempting to clear

a fault situation.

28

YASKAWA TOEP YAIA1U 02A YASKAWA AC Drive – A1000 6-Phase/12-Pulse Input Installation Manual

Loading…

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

YASKAWA AC Drive-A1000

High Performance Vector Control Drive

Quick Start Guide

Type: CIMR-AU A

Models: 200 V Class: 0.4 to 110 kW (3/4 to 175 HP ND)

400 V Class: 0.4 to 630 kW (3/4 to 1000 HP ND)

600 V Class: 0.75 to 75 kW (1 to 100 HP ND)

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

MANUAL NO. TOEP C710616 41B

Troubleshooting

Summary of Contents for YASKAWA A1000

Преобразователь частоты A1000 – это преобразователь частоты высочайшего уровня от компании YASKAWA. Он обеспечивает надёжность эксплуатации, экологические выгоды и экономию электроэнергии, а также множество иных эксплуатационных характеристик, ориентированных на пользователя, что делает данный преобразователь частоты превосходным выбором.

- Работа двигателей с постоянными магнитами без энкодера с максимальным крутящем моментом при нулевой скорости

-

Улучшенные функции автонастройки для автоматической корректировки параметров двигателя и постоянного анализа изменений во время работы двигателя для достижения самой высокой производительности оборудование

-

Улучшенный технология управления энергосбережением, которая повышает КПД и производительность оборудования при совместной работе с асинхронным и синхронным двигателем

- Доступны особые характеристики для высокой скорости вращения, позиционирования, кранов и лебёдок, электронного трансмиссионного вала

Технические характеристики

|

Тип: |

Преобразователь частоты общего назначения высочайшего уровня |

|

Диапазон: |

0,55 кВт — 630 кВт |

|

Максимальная мощность двигателя (кВт): |

3~200 VAC, 0.4 – 110 |

|

Применимые двигатели: |

Асинхронный двигатель (IM) |

|

Управление: |

Управление напряжением/частотой |

|

Диапазон регулирования скорости: |

Управление напряжением/частотой и Управление напряжением/частотой с PG 1:40 |

|

Регулировка крутящего момента: |

Стандарт |

|

Максимальная выходная частота: |

400 Гц |

|

Интерфейсные шины: |

RS-232C |

|

Стандарты: |

CE |

|

Степень защиты корпуса: |

IP00, IP20, IP54, NEMA1 |

|

Функции: |

Выключатель управления скоростью/крутящим моментом |

- Бренд

- Yaskawa

- Страна

- Япония

- Сегмент

- Общепромышленные преобразователи частоты

- Тип

- Преобразователь частоты

- Конструкция

- Общепромышленное применение

- Гарантия

- 3 года

-

Общий каталог Yaskawa A1000.pdf

Размер: 3 Мб

-

Техническое руководство A1000.pdf

Размер: 61 Мб

-

Инструкция по запуску Yaskawa A1000.pdf

Размер: 5 Мб

-

Каталог Yaskawa A1000+DriveWorkEZ 1.0.pdf

Размер: 9 Мб

- Manuals

- Brands

- YASKAWA Manuals

- Controller

- A1000 Series

Manuals and User Guides for YASKAWA A1000 Series. We have 16 YASKAWA A1000 Series manuals available for free PDF download: Technical Manual, Quick Start Manual, Installation Manual, Product Replacement Manual, Manual, Setup

YASKAWA A1000 Series Technical Manual (544 pages)

High Performance Vector Control Drive Models: 200 V Class: 0.4 to 110 kW 400 V Class: 0.4 to 355 kW

Brand: YASKAWA

|

Category: Controller

|

Size: 56.82 MB

Table of Contents

-

-

-

Applicable Documentation

16

-

Terms and Abbreviations

16

-

-

-

Supplemental Safety Information

17

-

Notes on Motor Operation

21

-

Applications with Specialized Motors

22

-

-

-

-

Control Mode Selection

28

-

Model Number and Nameplate Check

29

-

Drive Models and Enclosure Types

31

-

-

IP20/NEMA Type 1 Enclosure

32

-

-

Mechanical Installation

37

-

Installation Environment

40

-

2 Mechanical Installation

40

-

Installation Orientation and Spacing

40

-

Digital Operator Remote Usage

42

-

Exterior and Mounting Dimensions

46

-

-

Electrical Installation

51

-

Standard Connection Diagram

54

-

Main Circuit Connection Diagram

56

-

Three-Phase 200 V Class (CIMR-A 2A0169 to

56

-

Three-Phase 400 V Class (CIMR-A 4A0088 to 0675)

56

-

Terminal Block Configuration

57

-

-

CIMR-A 2A0004 to 0081, 4A0002 to 0044 (IP20/NEMA Type 1 Enclosure)

59

-

CIMR-A 2A0110 to 0415, 4A0058 to 0675 (IP00 Enclosure)

60

-

Removing/Reattaching the Digital Operator

61

-

Removing/Reattaching the Front Cover

61

-

-

Removing the Top Protective Cover

64

-

Reattaching the Top Protective Cover

64

-

-

-

Main Circuit Terminal Functions

65

-

Protecting Main Circuit Terminals

65

-

Wire Gauges and Tightening Torque

66

-

Main Circuit Terminal and Motor Wiring

70

-

Control Circuit Wiring

72

-

-

Control Circuit Connection Diagram

72

-

Control Circuit Terminal Block Functions

72

-

Terminal Configuration

73

-

Wiring the Control Circuit Terminal

74

-

Switches and Jumpers on the Terminal Board

76

-

Control I/O Connections

77

-

-

Sinking/Sourcing Mode Selection for Safe Disable Inputs

77

-

Sinking/Sourcing Mode Switch for Digital Inputs

77

-

Using the Pulse Train Output

78

-

Terminal A2 Input Signal Selection

79

-

Terminal A3 Analog/Ptc Input Selection

79

-

Terminal AM/FM Signal Selection

79

-

Memobus/Modbus Termination

80

-

Start-Up Programming & Operation

85

-

Using the Digital Operator

87

-

ALARM (ALM) LED Displays

89

-

LO/RE LED and RUN LED Indications

89

-

Menu Structure for Digital Operator

90

-

The Drive and Programming Modes

91

-

Navigating the Drive and Programming Modes

91

-

Changing Parameter Settings or Values

92

-

Verifying Parameter Changes: Verify Menu

94

-

Simplified Setup Using the Setup Group

95

-

Switching between LOCAL and REMOTE

96

-

Flowchart A: Basic Start-Up and Motor Tuning

98

-

Subchart A-1: Simple Motor Setup Using V/F Control

99

-

Subchart A-2: High Performance Operation Using OLV or CLV

100

-

Subchart A-3: Operation with Permanent Magnet Motors

101

-

Powering up the Drive

102

-

Powering up the Drive and Operation Status Display

102

-

Application Selection

103

-

Setting 1: Water Supply Pump Application

103

-

Setting 2: Conveyor Application

103

-

Setting 3: Exhaust Fan Application

104

-

Setting 4: HVAC Fan Application

104

-

Setting 5: Compressor Application

105

-

Setting 6: Hoist Application

105

-

Notes on Controlling the Brake When Using the Hoist Application Preset

106

-

Setting 7: Traveling Application

108

-

Before Auto-Tuning the Drive

111

-

Auto-Tuning Interruption and Fault Codes

112

-

Auto-Tuning Operation Example

112

-

Parameter Settings During Induction Motor Auto-Tuning: T1

114

-

Parameter Settings During PM Motor Auto-Tuning: T2

116

-

Parameter Settings During Inertia and Speed Control Loop Auto-Tuning: T3

119

-

No-Load Operation Test Run

121

-

Test Run with Load Connected

123

-

Test Run with the Load Connected

123

-

Verifying Parameter Settings and Backing up Changes

124

-

Backing up Parameter Values: O2-03

124

-

Parameter Access Level: A1-01

124

-

Password Settings: A1-04, A1-05

124

-

-

-

B1: Operation Mode Selection

136

-

B2: DC Injection Braking and Short Circuit Braking

144

-

B7: Droop Control (CLV, CLV/PM)

162

-

C1: Acceleration and Deceleration Times

165

-

C2: S-Curve Characteristics

167

-

C3: Slip Compensation

167

-

C4: Torque Compensation

170

-

C5: Automatic Speed Regulator (ASR)

171

-

C6: Carrier Frequency

177

-

D: Reference Settings

180

-

-

D1: Frequency Reference

180

-

D2: Frequency Upper/Lower Limits

182

-

D4: Frequency Reference Hold and Up/Down 2 Function

183

-

D6: Field Weakening and Field Forcing

192

-

E1: V/F Pattern for Motor 1

194

-

E2: Motor 1 Parameters

198

-

E3: V/F Pattern for Motor 2

201

-

E4: Motor 2 Parameters

202

-

E5: PM Motor Settings

204

-

F1: PG Speed Control Card Settings

206

-

F2: Analog Input Card Settings

209

-

F3: Digital Input Card Settings

209

-

F4: Analog Monitor Card Settings

210

-

F5: Digital Output Card Settings

211

-

F6: Communication Option Card

211

-

-

H: Terminal Functions

214

-

-

MECHATROLINK Parameters

213

-

PROFIBUS-DP Parameters

213

-

H1: Multi-Function Digital Inputs

214

-

H2: Multi-Function Digital Outputs

224

-

H3: Multi-Function Analog Inputs

234

-

H4: Multi-Function Analog Outputs

239

-

H5: Memobus/Modbus Serial Communication

241

-

H6: Pulse Train Input/Output

241

-

L: Protection Functions

244

-

-

L2: Momentary Power Loss Ride-Thru

249

-

-

N: Special Adjustments

275

-

-

N1: Hunting Prevention

275

-

N2: Speed Feedback Detection Control (AFR) Tuning

276

-

N3: High Slip Braking (HSB) and Overexcitation Braking

276

-

N5: Feed Forward Control

279

-

N8: PM Motor Control Tuning

281

-

O: Operator Related Settings

284

-

-

O1: Digital Operator Display Selection

284

-

O2: Digital Operator Keypad Functions

285

-

O4: Maintenance Monitor Settings

288

-

Q: Driveworksez Parameters

289

-

R: Driveworksez Connection Parameters

289

-

U: Monitor Parameters

291

-

-

U1: Operation Status Monitors

291

-

U4: Maintenance Monitors

291

-

U6: Operation Status Monitors

291

-

U8: Driveworksez Monitors

292

-

-

Fine-Tuning Open Loop Vector Control

296

-

Fine-Tuning V/F Control and V/F Control with PG

296

-

Motor Performance Fine-Tuning

296

-

Fine-Tuning Closed Loop Vector Control

297

-

Fine-Tuning Open Loop Vector Control for PM Motors

297

-

Fine-Tuning Advanced Open Loop Vector Control for PM Motors

298

-

Fine-Tuning Closed Loop Vector Control for PM Motors

298

-

Parameters to Minimize Motor Hunting and Oscillation

299

-

Drive Alarms, Faults, and Errors

300

-

Types of Alarms, Faults, and Errors

300

-

-

Alarm and Error Displays

301

-

Fault Displays, Causes, and Possible Solutions

306

-

Alarm Codes, Causes, and Possible Solutions

319

-

Operator Programming Errors

325

-

-

Ope Codes, Causes, and Possible Solutions

325

-

Auto-Tuning Fault Detection

328

-

-

Auto-Tuning Codes, Causes, and Possible Solutions

328

-

Copy Function Related Displays

332

-

-

Tasks, Errors, and Troubleshooting

332

-

Diagnosing and Resetting Faults

334

-

-

Fault Occurs Simultaneously with Power Loss

334

-

If the Drive Still Has Power after a Fault Occurs

334

-

Viewing Fault Trace Data after Fault

334

-

-

Troubleshooting Without Fault Display

336

-

Cannot Change Parameter Settings

336

-

Motor Does Not Rotate Properly after Pressing RUN Button or after

336

-

Entering External Run Command

337

-

Drive Does Not Allow Selection the Desired Auto-Tuning Mode

338

-

Ope02 Error Occurs When Lowering the Motor Rated Current Setting

338

-

Motor Stalls During Acceleration or Acceleration Time Is too Long

338

-

Excessive Motor Oscillation and Erratic Rotation

339

-

Deceleration Takes Longer than Expected with Dynamic Braking Enabled

339

-

Load Falls When Brake Is Applied (Hoist-Type Applications)

339

-

Noise from Drive or Output Lines When the Drive Is Powered on

340

-

Earth Leakage Circuit Breaker (ELCB) Trips During Run

340

-

Connected Machinery Vibrates When Motor Rotates

340

-

Insufficient Starting Torque

340

-

Output Frequency Is Not as High as Frequency Reference

341

-

Buzzing Sound from Motor at 2 Khz

341

-

Unstable Motor Speed When Using PM

341

-

Motor Does Not Restart after Power Loss

341

-

Advertisement

YASKAWA A1000 Series Technical Manual (628 pages)

High Performance Vector Control Drive

Type: CIMR-A series

Models: 200 V Class: 0.55 to 110 kW,

400 V Class: 0.55 to 630 kW

Brand: YASKAWA

|

Category: Controller

|

Size: 55.44 MB

Table of Contents

-

-

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

13

-

Applicable Documentation

16

-

Notes on Motor Operation

23

-

Applications with Specialized Motors

24

-

-

-

Model Number and Nameplate Check

32

-

Drive Models and Enclosure Types

33

-

Drive Models and Enclosure Types

34

-

2 Mechanical Installation

43

-

Mechanical Installation

48

-

Digital Operator Remote Usage

50

-

Exterior and Mounting Dimensions

52

-

-

Electrical Installation

57

-

Standard Connection Diagram

60

-

Standard Connection Diagram

62

-

Main Circuit Configurations

63

-

Main Circuit Configurations

65

-

Terminal Block Configuration

66

-

Terminal Block Configuration

67

-

Digital Operator and Front Cover

71

-

Protecting Main Circuit Terminals

76

-

Main Circuit Terminal and Motor Wiring

81

-

Control Circuit Wiring

83

-

-

Terminal Configuration

84

-

Wiring the Control Circuit Terminal

85

-

Switches and Jumpers on the Terminal Board

87

-

Control I/O Connections

88

-

-

Using the Pulse Train Output

89

-

Terminal A2 Input Signal Selection

90

-

Memobus/Modbus Termination

91

-

Start-Up Programming & Operation

97

-

Using the Digital Operator

99

-

ALARM (ALM) LED Displays

101

-

Menu Structure for Digital Operator

102

-

The Drive and Programming Modes

103

-

-

Changing Parameter Settings or Values

105

-

Verifying Parameter Changes: Verify Menu

106

-

Simplified Setup Using the Setup Group

107

-

Switching between LOCAL and REMOTE

108

-

Subchart A-1: Simple Motor Setup Using V/F Control

110

-

Subchart A-2: High Performance Operation Using OLV or CLV

111

-

Subchart A-3: Operation with Permanent Magnet Motors

112

-

Powering up the Drive

113

-

Application Selection

114

-

Setting 2: Conveyor Application

115

-

Setting 5: Compressor Application

116

-

Notes on Controlling the Brake When Using the Hoist Application Preset

117

-

Setting 7: Traveling Application

119

-

Before Auto-Tuning the Drive

123

-

Auto-Tuning Interruption and Fault Codes

125

-