Программируемый вискозиметр брукфильда

МОДЕЛЬ

DV-II+ Pro Инструкция

по

эксплуатации

Руководство

№

М/03-165

СОДЕРЖАНИЕ

I. ВВЕДЕНИЕ

I.1 Составные

части

вискозиметра

DV-II+

I.2 Требования к сети электропитания

I.3 Технические

данные

I.4 Настройка

I.5 Символы

безопасности

и

меры предосторожности

I.6 Функциональные

клавиши

I.7 Чистка

II. ПОДГОТОВКА

К

ИЗМЕРЕНИЮ

II.1 Автоматическая

настройка

нуля

II.2 Выбор

шпинделя

II.3 Выбор

и задание

скорости

II.4 Выбор

режима индикации дисплея II.5 Автоматический

выбор

диапазона II.6 Выход за пределы

диапазона

II.7 Индикация

температуры

II.8 Печать

II.9 Режим

внешнего управления

II.10 Эксплуатация

вискозиметра

II.11 Временные

режимы

для измерения

вязкости

II. ОПЦИИ

III.1 Введение

в

опции

III.2 Меню

установок

III.2.1 Дисплей

температуры III.2.2 Единицы

измерения

III.2.3 Выбор скорости

III.2.4 Порт

вывода на принтер

III.2.5 Усреднение

данных

III.3 Временные

режимы

III.3.1 Время остановки

III.3.2 Время

достижения

требуемого

момента вращения

III.3.3 Интервал

печати

III.3.4 Программирование

ПК

(включено/выключено)

III.3.5 Загрузка

программы

III.3.6 Запуск

программы

IV. ПО

DVLOADER

IV.1 Обзор

B.E.V.I.S.

IV.2 Описание

команд

B.E.V.I.S.

IV.3 Создание

программы

B.E.V.I.S. IV.4 Загрузка

программы

B.E.V.I.S. IV.5 Примеры

программ

V. АВТОМАТИЧЕСКИЙ

СБОР

И

АНАЛИЗ

ДАННЫХ

V.1 WINGATHER32

V.2 RHEOCALC32

Приложение

А

— Настройка

вискозиметра

с

конусом и пластиной

Приложение

В

— Диапазоны вязкости

Приложение

С

— Переменные

величины

при

измерении

вязкости

Приложение

D

— Коды шпинделей и моделей вискозиметров

Приложение

Е

— Методика

калибровки

Приложение

F

— Диапазоны специальных

скоростей

Приложение

G

— Подсоединение

Приложение

H

— Лабораторная подставка, модель

S

Приложение

I

— Зажим для датчика,

модель

DVE-50

Приложение

J

— Обнаружение

неисправностей

и

их устранение

Приложение

К

— Гарантийный ремонт и обслуживание

I. Введение

Вискозиметр

компании

«Brookfield»

DV-II+Pro

предназначен

для

измерения

вязкости

жидкости

при

заданных

значениях

скорости

сдвига.

Вязкость

—

это

мера

сопротивления

жидкости

к

истечению.

Подробный

математический

расчет

вязкости приводится

в

брошюре

«More

Solutions

to

Sticky

Problems»

(«Дополнительные

решения

проблем

измерения

вязкости»)

компании

«Brookfield»,

прилагаемой

к

приобретенному

Вами

вискозиметру

DV-II+Pro.

Вискозиметр

DV-II+Pro

предоставляет

многосторонность

в

режимах

управления

от

традиционного

ручного управления, автоматического управления посредством программ загруженных с

персонального

компьютера

(ПК)

до

полного

управления

ПК,

посредством

программного

обеспечения

«Brookfield

Rheocalc32»

• Вискозиметр

DV-II+Pro

может

использоваться

как

традиционный

вискозиметр

компании

«Brookfield»

для

сбора

показаний

вязкости

на

определенной

скорости

использую

клавиатуру

вискозиметра

для

выбора

шпинделя

и

скорости

вращения,

дисплея

для

чтения

показаний

(смотрите

раздел

II.

Подготовка

к

измерению)

• Программное обеспечение «Brookfield DVLoader» может использоваться для

программирования вискозиметра

DV-II+Pro

для

контроля

всех

аспектов

измерения,

сбора

показаний

измерения

без

необходимости

наблюдения

за

прибором;

правильности

запуск

программы

и

печати

показаний

(принтер

приобретается

отдельно)

(смотрите

раздел

IV.

Программное

обеспечение

DVLoader)

• Программное

обеспечение

«Brookfield

Rheocalc32»

позволяет

осуществлять

все

управление

и

функцию

сбора

показаний

посредством

ПК

обеспечивая

платформу

для

сбора

данных

и

их

анализа.(смотрите

раздел

II.9

Внешнее

управление)

Принцип

работы

вискозиметра

DV-II+Pro

основан

на

вращении

шпинделя

(погруженного

в

жидкую

пробу),

закрепленного

на

калиброванной

пружине.

Торможение

шпинделя,

возникающее

из-за

вязкости

жидкости,

замеряется

по

отклонению

пружины.

Отклонение

пружины

замеряется

ротационным

преобразователем.

Диапазон

измерения

вискозиметра

DV-II+Pro

(в

сантипуазах

или

миллипаскалях х

секунды)

определяется

скоростью

вращения

шпинделя,

его

размерами

и

формой,

формой

испытательного

контейнера,

в

котором

вращается

шпиндель,

и

полным

диапазоном

шкалы

вращающего

момента

калиброванной

пружины.

Компания

“Brookfield”

предлагает

четыре

основные

модели

в

зависимости

от

вращающего

момента пружины:

Вращающий

момент

-

Модель

LVDV-II+Pro

дин

х см673,7

мН

х м0,0673

RVDV-II+Pro

7187,0

0,7187

HADV-II+Pro

14374,0

1,4374

HBDV-II+Pro

57496,0

5,7496

Чем

выше

диапазон

калибровки

вращающего

момента,

тем выше

диапазон

измерения.

В

Приложении

В

указаны

диапазоны

измерения

для

каждого

диапазона

калибровки

вращающего

момента.

Все

единицы

измерения

индицируются

в

соответствии

с

системой

CGS

или

SI.

1.

На

дисплее

вискозиметра

DV-II+Pro

вязкость

индицируется

в

сантипуазах

(индикация

“сР”)

или

в

миллипаскалях

х

секунды

(индикация

“mPa•s”).

2.

2.Усилие

сдвига

индицируется

в

динах

на

квадратный

сантиметр

(“D/CM2”)

или

в

Ньютонах на

квадратный

метр

(“N/M2”).

3.

3.Скорость

сдвига

индицируется

в

величине,

обратной

секунде

(“1/SEC”).

4.

4.На

дисплее

вискозиметра

DV-II+Pro

вращающий

момент

индицируется

в

динах

х сантиметры

или

Ньютонах

х метры

(в

обоих

случаях

индикация

«%»).

Примечание:

Для изменения

формата

единиц

измерения

смотрите

раздел

III.2.2.)

Соответствующие единицы измерения системы SI определяются по следующим

соотношениям:

SI CGS

-

Вязкость:

1

мПа•с=

1

сПзУсилие

сдвига:1

Н/м2=

10

дин/см2Вращающий

момент:1

Н х м=

107

дин

х см

В

настоящей

инструкции

вязкость

указывается

в

единицах

системы

CGS.

Вискозиметр

DV-

II+Pro

обеспечивает

индикацию

и в единицах

системы

SI.

Соседние файлы в предмете [НЕСОРТИРОВАННОЕ]

- #

- #

- #

- #

- #

- #

- #

- #

- #

- #

- #

Brookfield Engineering Labs., Inc.

Page 5

Manual No. M03-165-F0612

I. INTRODUCTION

The Brookfield DV-II

+

Pro Viscometer measures fluid viscosity at given shear rates. Viscosity

is a measure of a fluid’s resistance to flow. You will find a detailed description of the science of

viscosity in the Brookfield publication “More Solutions to Sticky Problems” a copy of which was

included with your DV-II

+P

ro.

The DV-II+Pro offers exceptional versatility in modes of control allowing for traditional standalone

operation, automatic operation through programs downloaded from the PC or with complete

control by PC using Brookfield Rheocalc Software.

• The DV-II+Pro can be used as a traditional Brookfield viscometer for collection of single

speed viscosity data through the easy to use keypad; just select the spindle and speed and

read the value from the display. [See Section II, Getting Started]

• The Brookfield DVLoader Software can be used to program the DV-II+Pro to control all

aspects of the test and data collection without the need for the operator to monitor the

instrument; just start the program and return to the printed test data (printer is optional).

[See Section V, DVLoader Software]

• The Brookfield Rheocalc Software will perform all control and data collection functions of

the DV-II+Pro from the PC while also providing a platform for advanced data collection

and analysis. [See Section II.9, External Control]

In any of these modes of control, the DV-II+Pro will provide the best in viscosity measurement

and control.

The principal of operation of the DV-II

+

Pro is to drive a spindle (which is immersed in the test

fluid) through a calibrated spring. The viscous drag of the fluid against the spindle is measured by

the spring deflection. Spring deflection is measured with a rotary transducer. The measurement

range of a DV-II

+

Pro (in centipoise or milliPascal seconds) is determined by the rotational speed

of the spindle, the size and shape of the spindle, the container the spindle is rotating in, and the

full scale torque of the calibrated spring.

There are four basic spring torque series offered by Brookfield:

Spring Torque

Model

dyne/cm

milli Newton/m

LVDV-II

+

Pro

673.7 0.0673

RVDV-II

+

Pro

7,187.0 0.7187

HADV-II

+

Pro

14,374.0 1.4374

HBDV-II

+

Pro

57,496.0 5.7496

The higher the torque calibration, the higher the measurement range. The measurement range

for each torque calibration may be found in Appendix B.

All units of measurement are displayed according to either the CGS system or the SI system.

1. Viscosity appears in units of centipoise (shown as “cP”) or milliPascal-seconds (shown as

“mPa•s”) on the DV-II

+

Pro Viscometer display.

2. Shear Stress appears in units of dynes/square centimeter (“D/cm

2

”) or Newtons/square

meter (“N/m

2

”).

3. Shear Rate appears in units of reciprocal seconds (“1/SEC”).

4. Torque appears in units of dyne-centimeters or Newton-meters (shown as percent “%” in

both cases) on the DV-II

+

Pro Viscometer display.

Note: To change CGS to SI units on the display — see Section IV.2.2.

BROOKFIELD DV-II+

PROGRAMMABLE VISCOMETER

Operating Instructions

Manual No. M/97-164-F1102

SPECIALISTS IN THE

MEASUREMENT AND

CONTROL OF VISCOSITY

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346-1031 USA

TEL508-946-6200

F

AX

508-946-6262

Brookfield Engineering Labs., Inc. Page 1 Manual No. M/97-164-F1 102

or 800-628-8139 (USA only)

NTERNET

I

www.brookfieldengineering.com

TABLE OF CONTENTS

I. INTRODUCTION …………………………………………………………………………………………………………….3

I.1 Components ………………………………………………………………………………………………………….4

I.2 Utilities ………………………………………………………………………………………………………………….4

I.3 Specifications ………………………………………………………………………………………………………..5

I.4 Installation …………………………………………………………………………………………………………….6

I.5 Safety Symbols and Precautions………………………………………………………………………………7

I.6 Key Functions………………………………………………………………………………………………………..7

I.7 Cleaning ……………………………………………………………………………………………………………….9

II. GETTING STARTED ……………………………………………………………………………………………………..10

II.1 Autozero ……………………………………………………………………………………………………………..10

II.2 Spindle Selection…………………………………………………………………………………………………. 11

II.3 Speed Selection, Setting, Running………………………………………………………………………….12

II.4 Display Selection ………………………………………………………………………………………………….13

II.5 Autorange……………………………………………………………………………………………………………14

II.6 Out of Range ……………………………………………………………………………………………………….15

II.7 Temperature Display……………………………………………………………………………………………..16

II.8 Printing ……………………………………………………………………………………………………………….16

II.9 Making Viscosity Measurements …………………………………………………………………………….17

II.10 Time Modes for Viscosity Measurement…………………………………………………………………..18

III. OPTIONS…………………………………………………………………………………………………………………….. 19

III.1 Introduction to OPTIONS……………………………………………………………………………………….19

III.2 Setup ………………………………………………………………………………………………………………….21

III.2.1 Temperature Display…………………………………………………………………………………..22

III.2.2 Units of Measurement ………………………………………………………………………………… 22

III.2.3 Motor Speed Set Selection………………………………………………………………………….23

III.2.4 Printer Output Port………………………………………………………………………………………24

III.2.5 Data Averaging …………………………………………………………………………………………..24

III.3 Time Modes…………………………………………………………………………………………………………25

III.3.1 Time to Stop ………………………………………………………………………………………………26

III.3.2 Time to Torque ……………………………………………………………………………………………28

III.3.3 Print Time Interval……………………………………………………………………………………….30

III.3.4 PC Program (On/Off) …………………………………………………………………………………..31

III.3.5 Download a Program…………………………………………………………………………………..31

III.3.6 Run a Program …………………………………………………………………………………………..32

IV. DVLOADER SOFTWARE ……………………………………………………………………………………………..35

IV.1 B.E.V.I.S. Overview ………………………………………………………………………………………………35

IV.2 Description of B.E.V.I.S. Commands……………………………………………………………………….36

IV.3 Creating a B.E.V.I.S. Program………………………………………………………………………………..37

IV.4 Downloading a B.E.V.I.S. Program………………………………………………………………………….39

IV. 5 Example Programs ……………………………………………………………………………………………….40

Appendix A — Cone/Plate Viscometer Set-Up …………………………………………………………………42

Appendix B — Viscosity Ranges…………………………………………………………………………………….46

Appendix C — Variables in Viscosity Measurements…………………………………………………………49

Appendix D — Spindle and Model Codes ………………………………………………………………………..51

Appendix E — Calibration Procedures…………………………………………………………………………….54

Appendix F — Speed Sets…………………………………………………………………………………………….61

Appendix G — Communications …………………………………………………………………………………….62

Appendix H — Model S Laboratory Stand ……………………………………………………………………….65

Appendix I — DVE-50 Probe Clip………………………………………………………………………………….67

Appendix J — Fault Diagnosis and Troubleshooting…………………………………………………………68

Appendix K — Warranty Repair and Service ……………………………………………………………………72

Brookfield Engineering Labs., Inc. Page 2 Manual No. M/97-164-F1102

I. INTRODUCTION

The Brookfield Programmable DV-II+ Viscometer measures fluid viscosity at given shear rates.

Viscosity is a measure of a fluid’s resistance to flow. You will find a detailed description of the

mathematics of viscosity in the Brookfield publication ”More Solutions to Sticky Problems” a copy

of which was included with your DV-II+.

The principal of operation of the DV-II

+ is to drive a spindle (which is immersed in the test

fluid) through a calibrated spring. The viscous drag of the fluid against the spindle is measured

by the spring deflection. Spring deflection is measured with a rotary transducer. The measurement range of a DV-II

+ (in centipoise or milliPascal seconds) is determined by the rotational

speed of the spindle, the size and shape of the spindle, the container the spindle is rotating in, and

the full scale torque of the calibrated spring.

There are four basic spring torque series offered by Brookfield:

Spring Torque

Model dyne-cm milli Newton — m

LVDV-II

+ 673.7 0.0673

RVDV-II+ 7,187.0 0.7187

HADV-II+ 14,374.0 1.4374

HBDV-II+ 57,496.0 5.7496

The higher the torque calibration, the higher the measurement range. The measurement range for

each torque calibration may be found in Appendix B.

All units of measurement are displayed according to either the CGS system or the SI system.

1. Viscosity appears in units of centipoise (shown as “cP”) or milliPascal-seconds (shown

as “mPa•s”) on the DV-II+ Viscometer display.

2. Shear Stress appears in units of dynes/square centimeter (“D/cm2”) or Newtons/square

meter (“N/m2”).

3. Shear Rate appears in units of reciprocal seconds (“1/SEC”).

4. Torque appears in units of dyne-centimeters or Newton-meters (shown as percent “%”

in both cases) on the DV-II+ Viscometer display.

Note: To change CGS to SI units on the display — see Section III.2.2.

The equivalent units of measurement in the SI system are calculated using the following conversions:

SI CGS

Viscosity: 1 mPa•s = 1 cP

Shear Stress: 1 Newton/m

2

= 10 dyne/cm

2

Torque: 1 Newton-m = 107 dyne-cm

References to viscosity throughout this manual are done in CGS units. The DV-II+ Viscometer

provides equivalent information in SI units.

Brookfield Engineering Labs., Inc. Page 3 Manual No. M/97-164-F1 102

I.1 Components

Component Part Number Quantity

DV-II+ Viscometer varies 1

Model S Laboratory Stand MODEL S 1

Spindle Set with Case varies 1

LVDV-II+ set of four spindles SSL or

RVDV-II+ set of six spindles (#2 — #7) SSR or

HA/HBDV-II+ set of six spindles (#2 — #7) SSH

For Cone/Plate versions: a spindle wrench, one cone spindle and sample cup,

Part No. CPE-44Y replace the spindle set.

Power Cord 1

DVP-65 for 115 or

DVP-66 for 230

RTD Temperature Probe DVP-94Y 1

Guard Leg: 1

LVDV-II+ B-20Y

RVDV-II+ B-21Y

Carrying Case DVE-7Y 1

DVLOADER Software Disk (3-1/2″) DVLOADER 1

Interconnecting Cable DVP-80Y 1

Operating Manual M/97-164 1

Please check to be sure that you have received all components, and that there is

no damage. If you are missing any parts, please notify Brookfield Engineering or

your local Brookfield agent immediately. Any shipping damage must be reported

to the carrier.

I.2 Utilities

Input Voltage: 115 VAC or 230 VAC

Input Frequency: 50/60 Hz

Power Consumption: 30 VA

Power Cord Color Code:

United States Outside United States

Hot (live) Black Brown

Neutral White Blue

Ground (earth) Green Green/Yellow

Brookfield Engineering Labs., Inc. Page 4 Manual No. M/97-164-F1102

I.3 Specifications

Speeds: Interleaved: LV/RV (18 speeds)

Sequential: LV/RV (18 speeds)

Custom: 54 speeds, user selectable

Note: Refer to Appendix F for detailed list of all speeds.

Weight: Gross Weight 23 lbs. 10.5 kg.

Net Weight 20 lbs. 9 kg.

Carton Volume 1.65 cu. ft. 0.05 m

Temperature sensing range: -100˚C to 300˚C (-148˚F to 572˚F)

Analog Torque Output: 0 — 1 Volt DC (0 — 100% Torque)

Analog Temperature Output: 0 — 375 Volts DC (-100°C to +275°C)

RS232 Compatible Serial Port for use with an attached printer or PC.

Centronics Compatible Parallel Port for use with an attached printer.

Viscosity Accuracy: ±1.0% of full scale range

3

Viscosity Repeatability: ±0.2%

Temperature Accuracy: ±1°C : -100°C to +149°C

±2°C : +150°C to +300°C

Electrical Certifications: CUL, CE

Operating Environment: 0°C to 40°C temperature range (32°F to 104°F)

20% — 80%R.H.: non-condensing atmosphere

Electrical Certifications:

Conforms to CE Standards:

BSEN 50081-1: Emission Standard — Light Industrial

BSEN 50082-1: Immunity Standard — Light Industrial

BSEN 50081-2: Emission Standard — Industrial

BSEN 50082-2: Immunity Standard — Industrial

BSEN 61010-1: Safety requirements for electrical equipment, for measurement, control

and laboratory use

Approved Standards: CSA Class 8721 84 — Electrical Equipment for Laboratory Use

This product has been certified to the applicable CSA and ANSI/UL Standards, for use in

Canada and the U.S.

Installation Category (over voltage category) II: Classification of parts of installation

systems or circuits in local level, portable equipment, appliances, etc. (based on table 1 of

IEC 664).

Brookfield Engineering Labs., Inc. Page 5 Manual No. M/97-164-F1 102

I.4 Installation

Note: “IQ, OQ, PQ”, a guideline document for installation, operation and perfor-

mance validation for your DV-II+ digital viscometer can be downloaded from

our web site www.brookfieldengineering.com.

1) Assemble the Model S Laboratory Stand (refer to assembly instructions in Appendix H).

2) Put the viscometer on the stand.

3) Connect the RTD probe to the socket on the rear panel of the DV-II

+.

4) The Viscometer must be leveled. The level is adjusted using the two leveling screws on the

base. Adjust so that the bubble level on top of the DV-II+ is centered within the circle.

Note: Check level periodically during use.

5) Remove the white shipping cap which secures lower coupling nut on Viscometer to pivot

cup.

6) Make sure that the AC power switch at the rear of the DV-II+ is in the OFF position.

Connect the power cord to the socket on the back panel of the instrument and plug it into

the appropriate AC line.

The AC input voltage and frequency must be within the appropriate range as shown on the

nameplate of the viscometer.

Note: The DV-II+ must be earth grounded to ensure against electronic failure!!

7) Turn the power switch to the ON position and allow to warm up for 10 minutes before

performing autozero.

9) If appropriate, connect interconnecting cable to serial port for connection of DV-II+ to PC

or printer.

10) If appropriate, connect interconnecting cable to parallel port for connection of DV-II+ to

printer.

11) If appropriate, connect interconnecting cable to analog (serial) port for connection of DVII+ to chart recorder.

Brookfield Engineering Labs., Inc. Page 6 Manual No. M/97-164-F1102

I.5 Safety Symbols and Precautions

Safety Symbols

The following explains safety symbols which may be found in this operating manual.

Indicates hazardous voltages may be present.

Refer to the manual for specific warning or caution information to avoid personal injury

or damage to the instrument.

Precautions

If this instrument is used in a manner not specified by the manufacturer, the protection

provided by the instrument may be impaired.

This instrument is not intended for use in a potentially hazardous environment.

In case of emergency, turn off the instrument and then disconnect the electrical cord from

the wall outlet.

The user should ensure that the substtances placed under test do not release poisonous,

toxic or flammable gases at the temperatures which they are subjected to during the

testing.

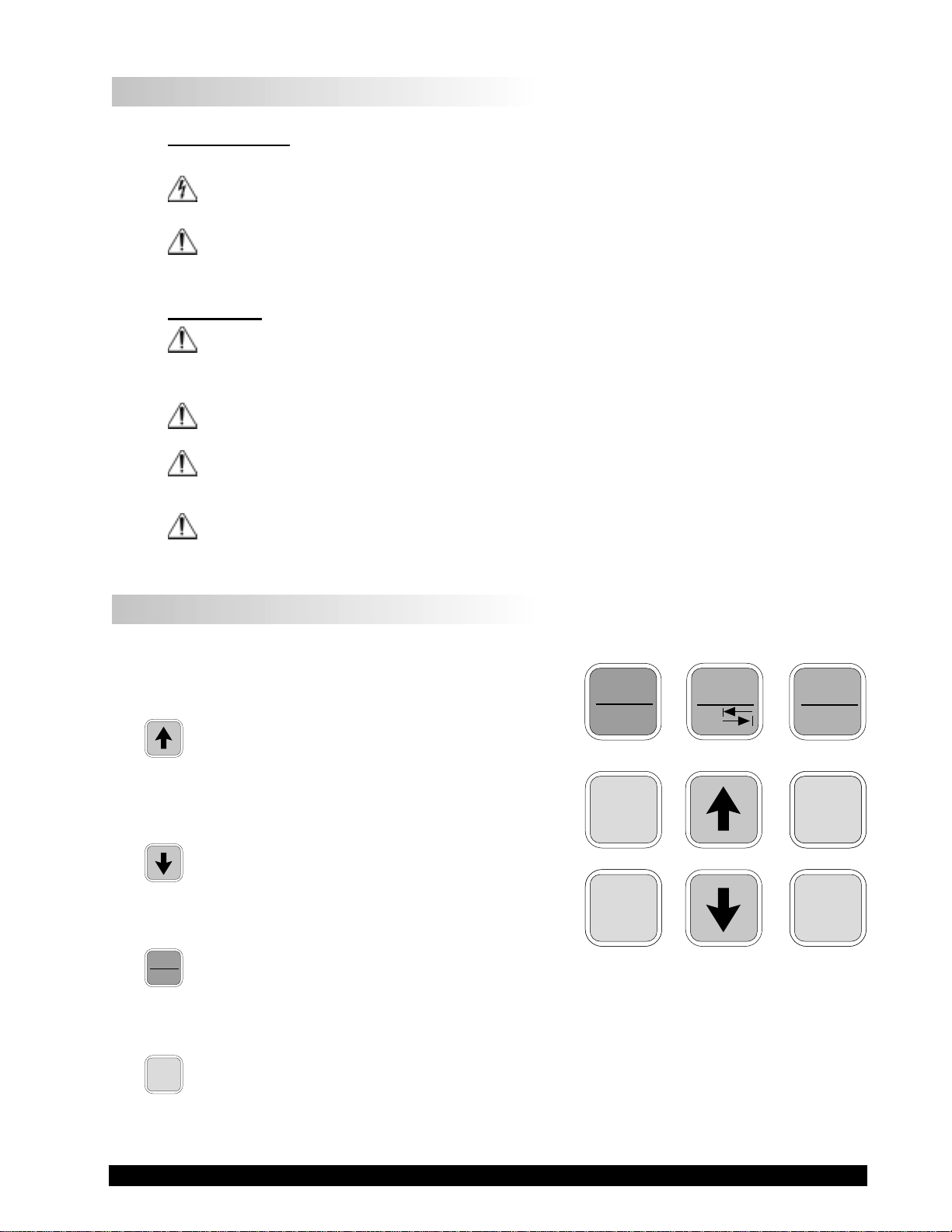

I.6 Key Functions

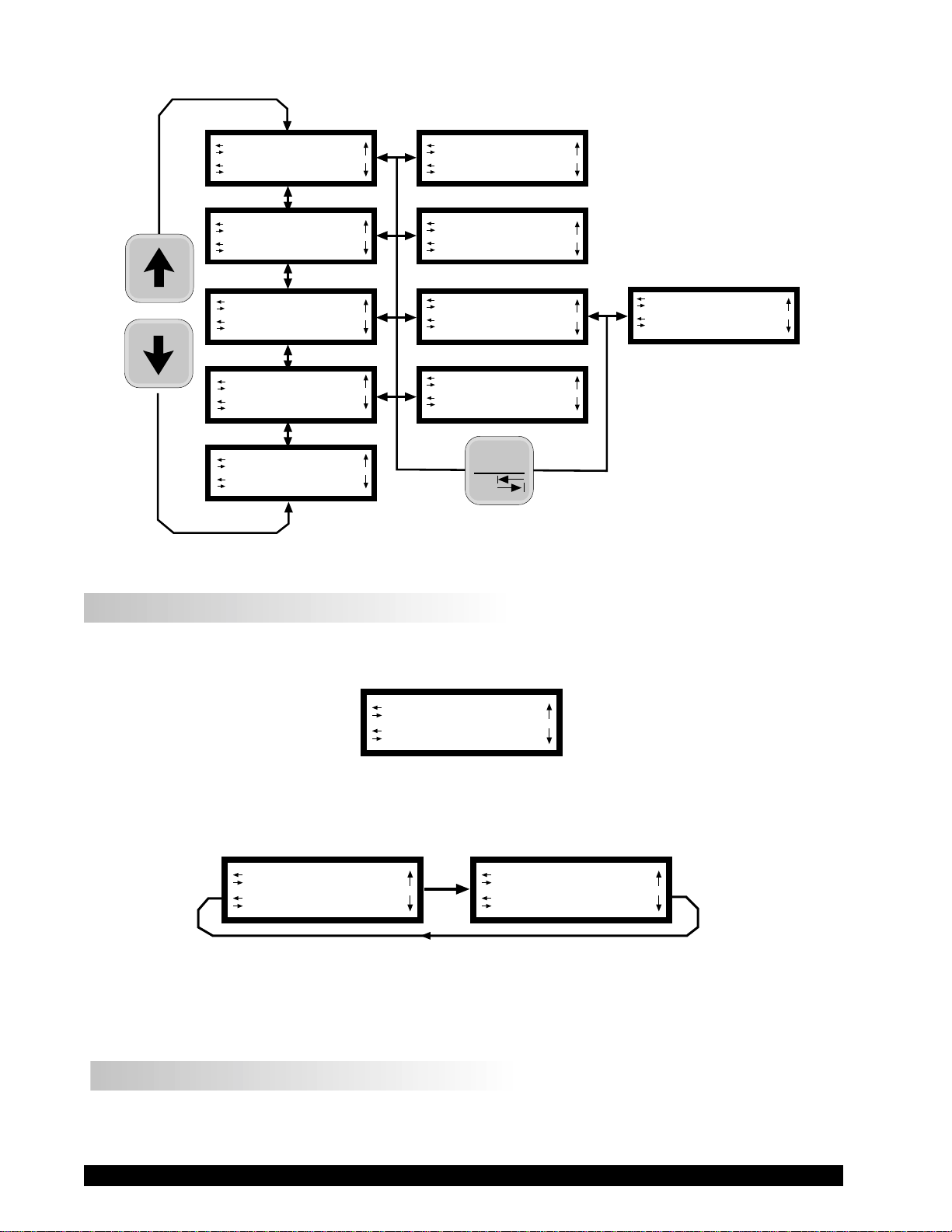

Figure 1 shows the control keys on the face of the DVII+ Viscometer. The following describes the function

of each key.

UP ARROW

This key is used to scroll UP (in an increasing

value direction) through the available speed,

spindle and Option menu tables.

DOWN ARROW

This key is used to scroll DOWN (in a decreasing

value direction) through the available speed,

spindle and option menu tables.

MOTOR

ON/OFF

ESCAPE

MOTOR ON/OFF/ESCAPE

Turns the motor ON or OFF. ESCAPE exits the

Options menu.

MOTOR

ON/OFF

ESCAPE

SET

SPEED

SELECT

DISPLAY

OPTIONS

TAB

Figure 1

ENTER

AUTO

RANGE

SELECT

SELECT

SPINDLE

SPINDLE

SET

SPEED

SET SPEED

Causes the DV-II+ to begin running at the currently selected speed. This function works

only when the motor is ON. Also used to select custom speeds when in the Custom Speed

option.

Brookfield Engineering Labs., Inc. Page 7 Manual No. M/97-164-F1 102

SELECT

DISPLAY

ENTER

AUTO

RANGE

SELECT

SELECT

SPINDLE

SPINDLE

SELECT DISPLAY

Selects the data parameter to be displayed:

cP Viscosity (cP or mPa.s)

SS Shear Stress (dynes/cm2 or Newtons/m2)

SR Shear Rate (1/sec)

ENTER/AUTO RANGE

ENTER: Used to execute the currently flashing option.

AUTO RANGE: Presents the maximum (100% torque) viscosity attainable using the

selected spindle at the current viscometer spindle speed.

SELECT SPINDLE

Initiates spindle selection on the first press and then selects the currently scrolled-to spindle

when pressed a second time.

Selects printing and non-printing modes when a printer is attached.

OPTIONS

TAB

OPTIONS/TAB

OPTIONS: Presents the Options menu, flashing the last escaped option.

TAB: Toggles between selectable items when indicated, as shown in Figure 2.

Note: Symbol indicating the

OPTIONS/TAB key

Note: Inverted text (black background with white lettering) indicates that the

information is flashing on the viscometer display.

L°F(FAHRENHEIT)

CGS UNITS

Figure 2

Brookfield Engineering Labs., Inc. Page 8 Manual No. M/97-164-F1102

I.7 Cleaning

Be sure to remove the spindle from the instrument prior to cleaning. Severe instrument damage may result if the spindle is cleaned in place.

Instrument and Keypad: Clean with a dry, non-abrasive cloth. Do not use solvents

or cleaners.

Immersed Components (spindles): Spindles are made of stainless steel. Clean with a non-

abrasive cloth and solvent appropriate for sample material.

Note: When cleaning, take care not to apply excessive force — it may bend the spindles.

Brookfield Engineering Labs., Inc. Page 9 Manual No. M/97-164-F1 102

II. GETTING STARTED

II.1 Autozero

Before readings may be taken, the Viscometer must be Autozeroed. This action is performed each

time the power switch is turned on. The display window on the Viscometer will guide you through

the procedure as follows:

Turn the power switch (located on the rear panel) to the ON position. This will result in the screen

display shown in Figure 3. The viscosity measurement range is indicated by the information in the

lower left, in this case RV. For most DV-II+ Viscometers, this information will be either “LV” or

“RV”.

BROOKFIELD DV-2+

RV VISCOMETER

Figure 3

After a few seconds, the following screen appears:

BROOKFIELD DV-2+

VERSION: 6.1

Figure 4

No key press is required at this point. After a short time, the display will clear and the following

will be displayed:

REMOVE SPINDLE

PRESS ANY KEY

Figure 5

After removing the spindle and pressing any key, the DV-II+ begins its Autozero. The screen will

flash «Autozeroing.»

After approximately 15 seconds, the display shows the screen in Figure 6:

REPLACE SPINDLE

PRESS ANY KEY

Figure 6

Pressing any key at this point results in the display of the DV-II+ default screen:

CP 0.0 20.1C

OFFRPM % 0.0

Figure 7

The display will vary depending upon the selection of temperature (°F or °C) and units of viscosity

(cP or mPa•s).

Brookfield Engineering Labs., Inc. Page 10 Manual No. M/97-164-F1102

SELECT

SELECT

II.2

Spindle Selection

SPINDLE

SPINDLE

LVDV-II+ Viscometers are provided with a set of four spindles and a narrow guardleg; RVDV-II+

Viscometers come with a set of six spindles and a wider guardleg; HADV-II+ and HBDV-II+

Viscometers come with a set of six spindles and no guardleg. (See Appendix E for more information

on the guardleg.)

The spindles are attached to the viscometer by screwing them onto the lower shaft. Note that the

spindles have a left-hand thread. The lower shaft should be secured and slightly lifted with one hand

while screwing the spindle to the left. The face of the spindle nut and the matching surface on the

lower shaft should be smooth and clean to prevent eccentric rotation of the spindle. Spindles can be

identified by the number on the side of the spindle coupling nut.

The DV-II+ must have a Spindle Entry Code number to calculate Viscosity, Shear Rate and Shear

Stress values. The DV-II

+ memory contains parameters for all standard Brookfield spindles

including custom spindles and the two digit entry code for each spindle (the complete list of entry

codes may be found in Appendix D).

Note: The DV-II+ will remember the Spindle Entry Code which was in use when the

power was turned off.

Pressing the SELECT SPINDLE key will display the current selected spindle code instead of

temperature and cause the character S to begin to blink . It will blink for about three seconds. If the

UP or DOWN ARROW keys are pressed (while S is blinking) the two character spindle value to the right

of the S character will begin to change (in either an increasing or decreasing direction depending upon

which ARROW key is pressed) for each press of the key. If the ARROW key is pressed and held, the

display will scroll through the spindle codes for as long as the ARROW key is depressed. When it

reaches the last item in the list (either at the top or bottom of the list) the spindle code displayed will

“roll-over” to either the first or last spindle code and the scroll action will continue.

When the desired spindle code is displayed, release the ARROW key to halt further scrolling. Press

the SELECT SPINDLE key once again. This will cause the S character to cease blinking and the new

spindle code will be accepted for use in viscometer calculations.

Note: You have approximately three seconds in which to press the SELECT SPINDLE

key before the

before the

the desired spindle.

blinking

blinking

stops. If you fail to press the SELECT SPINDLE key

stops you will have to repeat the above steps and re-select

The DV-II+ will begin to calculate using the new spindle parameters as soon as the SELECT SPINDLE

key is pressed the second time.

Note: The number 99 spindle is for use with special spindles when using Brookfield’s

WINGATHER computer program. Refer to the WINGATHER operator manual for

further information on using “99” spindles.

The DV-II+ may also be programmed at Brookfield Engineering for “special” user spindles. These

“special” spindles will appear on the spindle scroll list starting with designation “AA” and continuing

through “AZ”. Contact Brookfield Engineering regarding your needs for special spindles.

Brookfield Engineering Labs., Inc. Page 11 Manual No. M/97-164-F1 102

II.3

Speed Selection, Setting, Running

SET

SPEED

There are 54 speeds programmed into the DV-II+. These speeds correspond to the standard LVT,

RVT, HAT and HBT dial models (18 possible speeds altogether) plus 36 additional speeds.

The DV-II+ comes with the Sequential Speed Set already selected (see Appendix F). The speed set

will start at speed 0.0. It will then scroll up through the LV speeds, pass through speed 0.0 again, and

then scroll up through the RV speeds, pass through speed 0.0 again and then repeat the above

sequence.

The DV-II

+ can also be configured by the operator to interleave the LV and RV speeds. See Section

III.2.3 on Setup for a description of how to install the Interleave Speed Set.

A complete list of speed sets and custom speeds is included in Appendix F. The DV-II+ can be

programmed to select up to 19 of the 54 speeds for use at any one time. Speed 0.0 is the 20th speed

and is automatically included. See Section III. 2.3.2 on Setup for a description of how to install a

Custom Speed Set.

To select a Viscometer speed first press either the

UP or DOWN arrow keys which will cause the area

to the right of RPM to display the currently selected speed. Figure 8 shows the DV-II+ is operating

at 6.0 RPM, and the current selected speed is 6.0 RPM.

cP 123.4 20.1C

6.0RPM6.0 % 15.6

Figure 8

If the ARROW key is pressed just once and then released, the characters “RPM” will blink for three

seconds, then will cease blinking resulting in no change to the speed entry.

Note: The speed selection process remembers the last value of scrolled-to speed so

that the next time you initiate a speed change (by pressing an ARROW key), the

DV-II+ will begin its scroll display from the last entered value.

The last-scrolled-to speed does not necessarily have to be the same as the speed at which the DVII+ is currently running. The user may operate at a given speed and pre-set the DV-II+ to the next

desired speed before that speed will be used. For example, if the DV-II+ is currently running at 6.0

RPM and was previously scrolled to 12 RPM, a single press of either ARROW key would result in

the Figure 9 screen display:

cP 123.4 20.1C

6.0RPM12 % 15.6

Figure 9

Pressing the SET SPEED key would cause the DV-II+ to begin running at 12 RPM.

If the user did not press the SET SPEED key, the DV-II+ would continue to run at its current speed

of 6 RPM. In fact, you may scroll to a new speed (12 RPM in this example) and press the SET SPEED

key at any future time (without further pressing an ARROW key) to immediately cause the DV-II+

to run at the new speed. Pressing the ARROW key at any time reminds the operator of what was

selected for the next speed.

Brookfield Engineering Labs., Inc. Page 12 Manual No. M/97-164-F1102

If an ARROW key is pressed and held the DV-II+ will scroll up (or down) through the speed table.

When it reaches the last speed in the list (either at the top or bottom of the list) the speed displayed

will “roll-over” to either the first or last speed in the table and the scroll action will continue.

When the required speed is displayed, release the ARROW key to halt further scrolling. You have

approximately two seconds (before the blinking RPM stops) in which to press the SET SPEED key

to immediately begin rotation at the new speed.

Pressing the MOTOR ON/OFF/ESCAPE key stops the Viscometer spindle rotation. Pressing this key

sets the DV-II+ to 0.0 RPM and causes the screen display to change as shown in Figure 10:

cP 0.0 20.1C

OFFRPM % 0.0

Figure 10

Pressing the MOTOR ON/OFF/ESCAPE key again immediately starts the DV-II+ running at the last

scrolled-to-speed. If you had been running at 12 RPM, pressed MOTOR ON/OFF/ESCAPE and then

re-started the DV-II+ by pressing MOTOR ON/OFF/ESCAPE once again, you would again be running

at 12 RPM. However, if while the motor was off you had scrolled to a new speed of 0.5 RPM, pressing

the MOTOR ON/OFF/ESCAPE key would start the DV-II+ running at 0.5 RPM.

Note: During both spindle or speed selection and scrolling operations, the DV-II+ will

continue to calculate and display Viscometer data as selected.

SELECT

DISPLAY

II.4

Display Selection

Viscosity (displayed in units of cP or mPa•s), Shear Stress and Shear Rate are displayed on the left

side of the top line. You may “step” through the three display options by pressing the SELECT

DISPLAY key. For example, the DV-II+ is currently displaying Viscosity as shown in Figure 11:

cP 123e3 20.1C

6.0RPM % 15.6

Figure 11

If the viscosity value exceeds 99,999 scientific notation is used. In Figure 11, the viscosity value is

123,000 cP.

The first press of the SELECT DISPLAY key would display Shear Stress (SS) in Dynes/cm2 (or

Newtons/m2), see Figure 12:

SS 29.0 20.1C

6.0RPM % 15.6

Figure 12

If the shear stress value exceeds 99,999, scientific notation is used.

The next press of the SELECT DISPLAY key would display Shear Rate (SR) in 1/Sec; see Figure 13.

Brookfield Engineering Labs., Inc. Page 13 Manual No. M/97-164-F1 102

SR 40.0 20.1C

6.0RPM % 15.6

Figure 13

One more press of the SELECT DISPLAY key would result in a return to the viscosity screen, as shown

in Figure 11.

Notes: 1. You may step through the display at any time. This will not interrupt any

Viscometer calculations that are in progress.

2. Display of shear rate and shear stress requires selection of appropriate

spindles. Otherwise, values displayed will be zero (0).

Units of Measurement

The DV-II+ Viscometer can be configured using the SETUP option (Section III.2.2) to display/

print in either the CGS or SI system of units.

ENTER

II.5

The ENTER/AUTO RANGE key functions as auto range and allows you to determine the maximum

calculated viscosity (full scale reading) possible with the current spindle/speed setting only when in

the default screen. Pressing the key at any time will cause the current viscosity display to change and

show that maximum viscosity. The screen area displaying % (torque) will now display a flashing

“%100.0” to indicate this special condition. This maximum viscosity and flashing %100.0 value will

be displayed for as long as the ENTER/AUTO RANGE key is depressed. Figure 14 shows the AUTO

RANGE function for the situation where the No. 1 LV spindle is rotating at 60 rpm. The full scale

range is 100.0 cP (or 100.0 mPa.s).

Autorange

AUTO

RANGE

cP 100.0 S61

60 RPM % 100

Figure 14

Notes: 1. If the RPM is 0.0, the maximum viscosity displayed will be 0.0 cP (or 0.0

mPa.s).

2. While the Viscometer is in the Auto Range mode, any data sent to an

attached printer or computer reflects the displayed values (i.e. Auto Range

values).

3. This function is only available when in the default screen.

Brookfield Engineering Labs., Inc. Page 14 Manual No. M/97-164-F1102

II.6 Out of Range

The DV-II+ gives indications for out-of-range operation. When % (Torque) readings exceed 100%

(over-range), the display changes to that shown in Figure 15; EEEE will also appear in the display

for % and viscosity or shear stress:

cP EEEE 20.1C

10 RPM % EEEE

Figure 15

You must change either speed or spindle to correct this condition. If you operate at spindle speeds

that produce % (Torque) below 10.0 %, the DV-II+ flashes the % (Torque), cP (Viscosity), SS

(Shear Stress) and SR (Shear Rate) as shown in Figure 16:

cP 12.4 20.1C

10 RPM % 8.2

Figure 16

Negative % (Torque) will be displayed as shown in Figure 17:

cP —- 20.1C

10 RPM % -2.2

Figure 17

Figure 18 is an example of the printed output of each of the above conditions.

Normal Operation:

RPM=50 M=RV S=29 %=51.4 cP=10280 D/CM2=1285 1/SEC=12.3 T=20.1C Z00:30

Over-Range Operation (>100% torque) (see Fig. 15):

RPM=50 M=RV S=29 %=EEEE cP=EEEE D/CM2=EEEE 1/SEC=12.3 T=20.1C Z00:30

Under-Range Operation (<10% torque) (see Fig. 16):

?RPM=50 M=RV S=29 %=5.2 cP=1040 D/CM2=130 1/SEC=12.3 T=20.1C Z00:30

Negative Torque Operation (see Fig. 17):

RPM=50 M=RV S=29 %=-0.1 cP=—- D/CM2=—- 1/SEC=12.3 T=20.1C Z00:30

M = Torque Range T = Temperature Z = Time

Figure 18

Brookfield Engineering Labs., Inc. Page 15 Manual No. M/97-164-F1 102

II.7 Temperature Display

The DV-II

+ displays the temperature measured by its RTD temperature probe. Temperature may be

displayed in either ˚C (Centigrade) or ˚F (Fahrenheit) units, depending upon selection from the

Options menu. As received, the default temperature display will be in ˚C (Centigrade) units as shown

in the Figure 19:

cP 123.4 20.1C

10 RPM % 19.7

Figure 19

If you turn on the DV-II+ with the temperature probe disconnected, or remove the temperature probe

at any point after power-up, the display will indicate “- — — -C”. The four “dashes” indicate the absence

of the probe. If you were displaying temperature in Fahrenheit units the C would be replaced by an

F. Accuracy of temperature measurement for the DV-II+ is shown in Table 1.

Table 1

Temperature Accuracies for

Programmable DV-II+ Viscometer

Temperature Range Temperature Accuracy

-100°C to +149°C ±1.0°C

+150°C to +300°C ±2.0°C

II.8

Printing

The DV-II+ will print data to an attached Serial (RS232) or Parallel (centronics) printer. The printer

must be attached to the appropriate rear panel output connector. See Appendix G for configuration

and connection requirements.

Data may be printed in two ways:

1. Pressing the PRINT key once (for less than three (3) seconds) will result in the printing of one

standard print line.

2. If the PRINT key is pressed and held for more than three (3) seconds, the DV-II+ will then begin

continuous printer output at a print rate interval selected via the Options menu (see Section III.4).

The display will show a flashing P in front of the % sign. See Figure 20.

cP 123.4 20.1C

10 RPM P% 19.7

Figure 20

To stop continuous printing, press the PRINT key for one (1) second. The flashing P will

disappear on the viscometer display.

Figure 21 is an example of the print strings for CGS and SI units.

Brookfield Engineering Labs., Inc. Page 16 Manual No. M/97-164-F1102

For the case of CGS units with non-exponential results:

11020304050607080

RPM=XXX M=XXXXX S=XX %=XXX.X cP=XXXXX D/CM2=XXXXX 1/SEC=XXXXX T=XX.XC ZXX=XX

and CGS units with exponential results.

11020304050607080

RPM=XXX M=XXXXX S=XX %=XXX.X cP=XXXeX D/CM2=XXXeX 1/SEC=XXXXX T=XX.XC ZXX=XX

Similarly, for SI units with non-exponential results.

11020304050607080

RPM=XXX M=XXXXX S=XX %=XXX.X mPas=XXXXX N/M2=XXXXX 1/SEC=XXXXX T=XX.XC ZXX=XX

and SI units with exponential results.

11020304050607080

RPM=XXX M=XXXXX S=XX %=XXX.X mPas=XXXeX N/M2=XXXeX 1/SEC=XXXXX T=XX.XC ZXX=XX

M = Torque T = Temperature Z = Time

Figure 21

When printing via the parallel port, please note that if a printer is not attached to the viscometer,

the following screen appears:

PRINTER ERROR

CHECK CONNECTION

Figure 22

II.9 Making Viscosity Measurements

The following general procedure is used for making viscosity measurements. Brookfield recommends the use of a 600 ml Low Form Griffin beaker when using LV/RV/HA/HB spindles.

1. Mount the guardleg on the DV-II+ Viscometer (LV and RV series) and insert into the container.

2. Insert and center spindle in the test material until the fluid’s level is at the immersion groove on

the spindle’s shaft. With a disc-type spindle, it is necessary to tilt the spindle slightly while

immersing to avoid trapping air bubbles on its surface. Attach the spindle to the lower shaft of

the viscometer. Lift the shaft slightly, holding it firmly with one hand while screwing the spindle

on with the other (note left-hand thread). Avoid putting side thrust on the shaft. Verify the proper

spindle immersion depth and that the viscometer is level.

3. The process of selecting a spindle and speed for an unknown fluid is normally trial and error. An

appropriate selection will result in measurements made between 10-100 on the instrument

% torque scale. Two general rules will help in the trial and error process.

1) Viscosity range is inversely proportional to the size of the spindle.

2) Viscosity range is inversely proportional to the rotational speed.

To measure high viscosity, choose a small spindle and/or a slow speed. If the chosen spindle/

speed results in a reading above 100%, then reduce the speed or choose a smaller spindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory

results between 10-100%. When this circumstance occurs, any of the spindles may be selected.

Brookfield Engineering Labs., Inc. Page 17 Manual No. M/97-164-F1 102

Non-Newtonian fluid behavior can result in the measured viscosity changing if the spindle and/

or speed is changed. See our publication, “More Solutions to Sticky Problems,” for more detail.

Turn on motor.

Allow time for the indicated reading to stabilize. The time required for stabilization will depend

on the speed at which the Viscometer is running and the characteristics of the sample fluid. For

maximum accuracy, readings below 10% should be avoided.

Record values.

4. Press the

MOTOR ON/OFF/ESCAPE key and turn the motor “OFF” when changing a spindle or

changing samples. Remove spindle before cleaning.

5. Interpretation of results and the instrument’s use with non-Newtonian and thixotropic materials

is discussed in the booklet, «More Solutions to Sticky Problems», and in Appendix C, Variables

in Viscosity Measurements.

II.10 Time Modes for Viscosity Measurement

The Time Modes allow the viscometer user to implement the unattended Time to Stop and Time to

Torque capabilities of the DV-II+ Viscometer. These features will allow the user to set up the

viscometer (i.e. select spindle and speed) and then record readings for a fixed period of time (Time

to Stop) or until a set torque value is attained (Time to Torque). When timing begins, a message will

be displayed showing time remaining (or time elapsed) and the appropriate display item (viscosity

or torque) will be updated continuously during the event. Upon completion, the viscometer will stop

and display a screen stating that the test is complete and will also display the final recorded value for

the viscosity in the first case, or the time in minutes and seconds to reach the torque limit in the second

case. Pressing the UP or DOWN ARROW keys will allow additional viscometer data to be examined.

Pressing any other key (except the PRINT or ENTER/AUTORANGE key) will bring the user back to the

default (normal) viscometer display with the motor OFF. Refer to the Time Modes in Section III.3.

Brookfield Engineering Labs., Inc. Page 18 Manual No. M/97-164-F1102

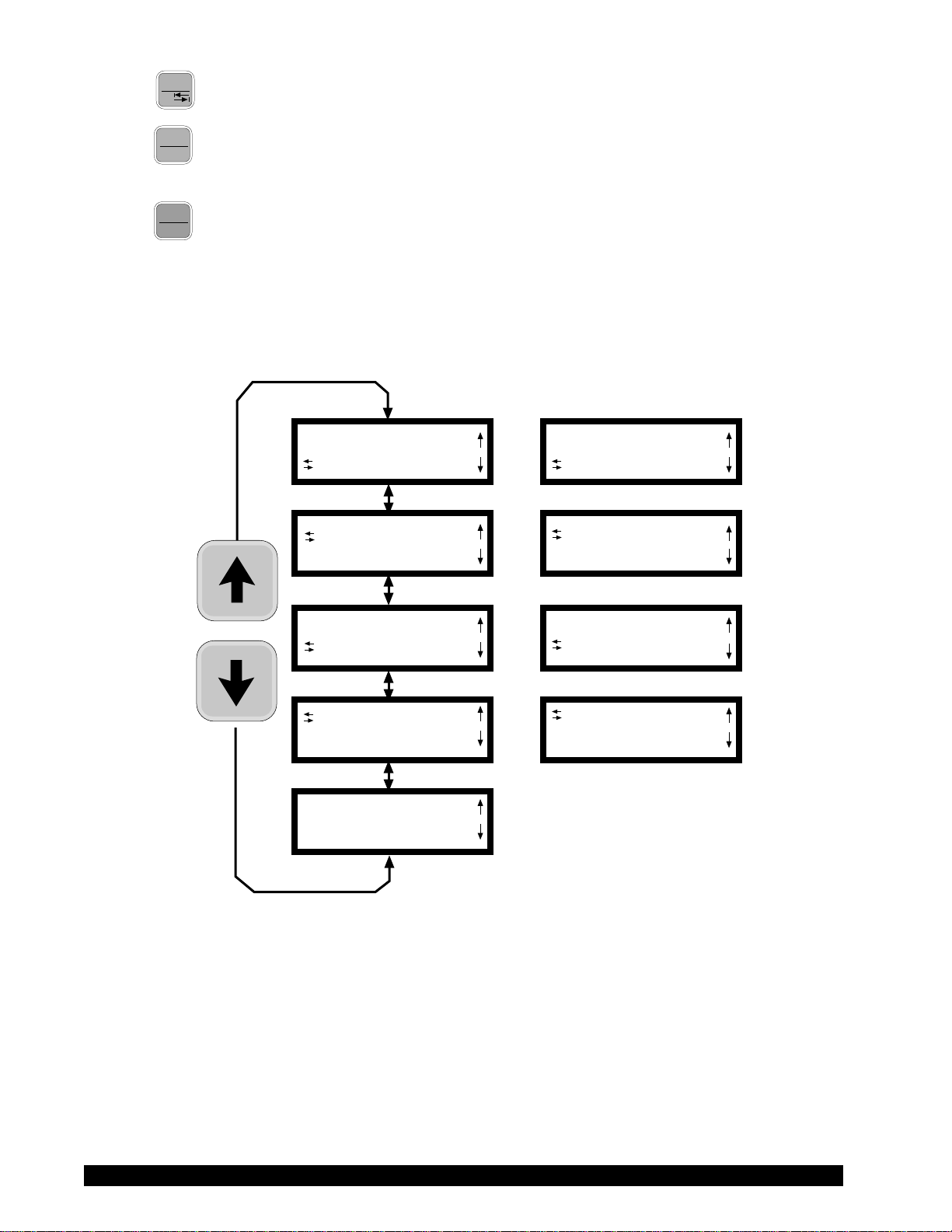

III. OPTIONS

OPTIONS

III.1

The OPTIONS/TAB key provides access to the configuration (Setup) of the DV-II+ Viscometer as

well as special functions that can enhance the user’s ability to make viscosity measurements.

The Options menu, shown in Table 1, gives a complete picture of the various configuration

choices and special functions.

Quick References to Options

Introduction to OPTIONS

TAB

SETUP:

Temperature — °F or °C

Units — CGS or SI

* Speed Sets — Sequential, Interleave, Custom

Printer Port — Serial (RS232) or Parallel

Data Averaging — Display Only

Table 2

Options Menu

* TIME TO STOP

* TIME TO TORQUE

SET PRINT TIME:

Set the Printing Time

PC PROG (ON/OFF):

Enables/Disables Communication of Serial (RS232) Port

* DOWNLOAD A PROGRAM:

Link to PC to Receive a B.E.V.I.S. Program

(B.E.V.I.S. = Brookfield Engineering Viscometer Instruction Set)

* RUN A PROGRAM:

Execute a B.E.V.I.S. Program

*Not available when motor is ON

Pressing OPTIONS/TAB places you into the Options menu at the last option selected. The following

keys are active and perform as follows:

UP ARROW — Scrolls up through menu or selects new value from

list.

DOWN ARROW — Scrolls down through menu or selects new value

from list.

Brookfield Engineering Labs., Inc. Page 19 Manual No. M/97-164-F1 102

OPTIONS

OPTIONS/TAB — Toggles between options.

TAB

ENTER

ENTER/AUTORANGE — Accepts the currently flashing option and moves

AUTO

RANGE

user to next level (if applicable) of the selected

option.

MOTOR

ON/OFF

MOTOR ON/OFF/ESCAPE — Cancels current operation and backs user out one

ESCAPE

menu level. Repeated pressing will back the user

out to the default screen. While in the Options

menu, the

MOTOR ON/OFF/ESCAPE key does not

cause the viscometer motor to turn on or off!

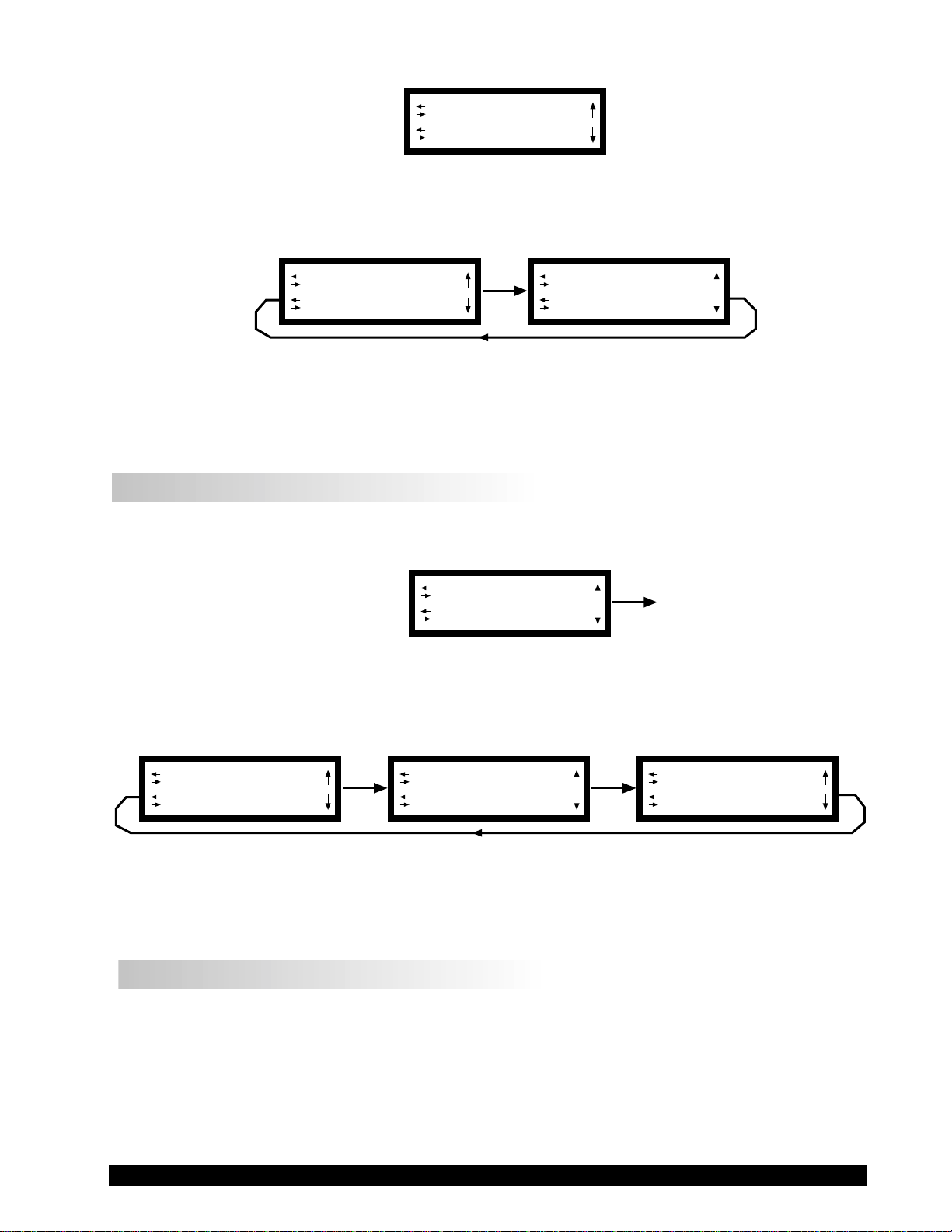

The Options menu screens will appear as shown in Figure 23 if you cycle through the

possible options using the

UP/DOWN arrows.

SETUP

TIME TO TORQUE

TIME TO TORQUE

SET PRINT TIME

SET PRINT TIME

PC PROG OFF

PC PROG OFF

DOWNLOAD A PROG

DOWNLOAD A PROG

RUN A PROG

OR

OR

OR

OR

SETUP

TIME TO STOP

LTIME TO STOP

SET PRINT TIME

SET PRINT TIME

PC PROG ON

LPC PROG ON

DOWNLOAD A PROG

Figure 23

On entry to the Options menu, the following rules regarding current viscometer operation are in force:

1. Printer output will be suppressed when in the Custom Speed option, the Time to

Torque and Time to Stop options, the Download A Program and Run A Program

options. It will be continued when any other option is selected.

2. If the motor is ON when the user enters the Options menu, choices will be limited

to: CGS/SI units (under SETUP), °F/°C units (under SETUP), PRINTING SELECTIONS and PC PROG.

3. The last selected menu option will be flashing.

Brookfield Engineering Labs., Inc. Page 20 Manual No. M/97-164-F1102

Selecting an Option

The following is a quick reference for entering and using the OPTIONS menu:

Press

Press

OPTIONS

TAB

To enter Options Menu

or To scroll to a specific option

For Options:

Press

Press

OPTIONS

TAB

ENTER

AUTO

RANGE

To toggle between the choices available for a specific option when indicated

To select the flashing option

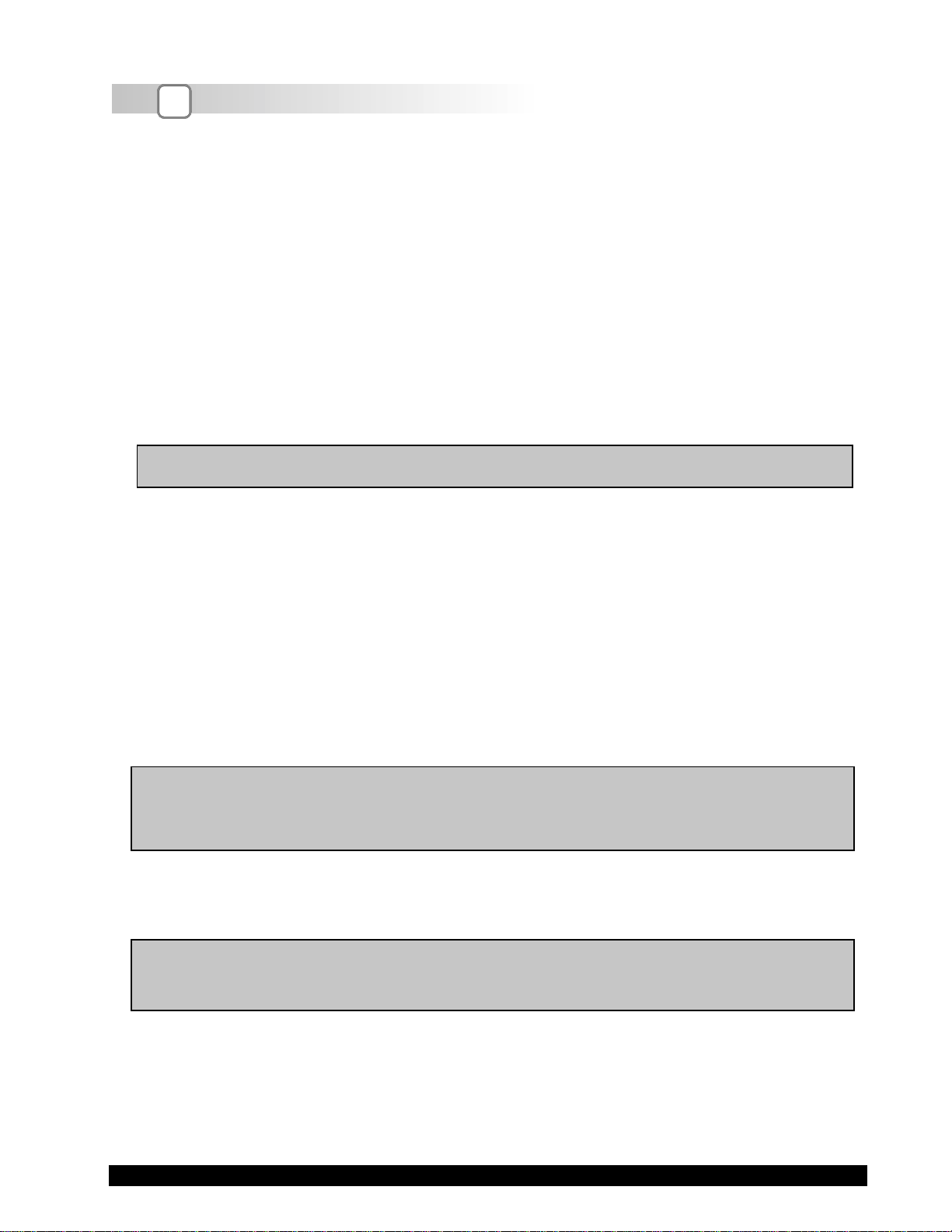

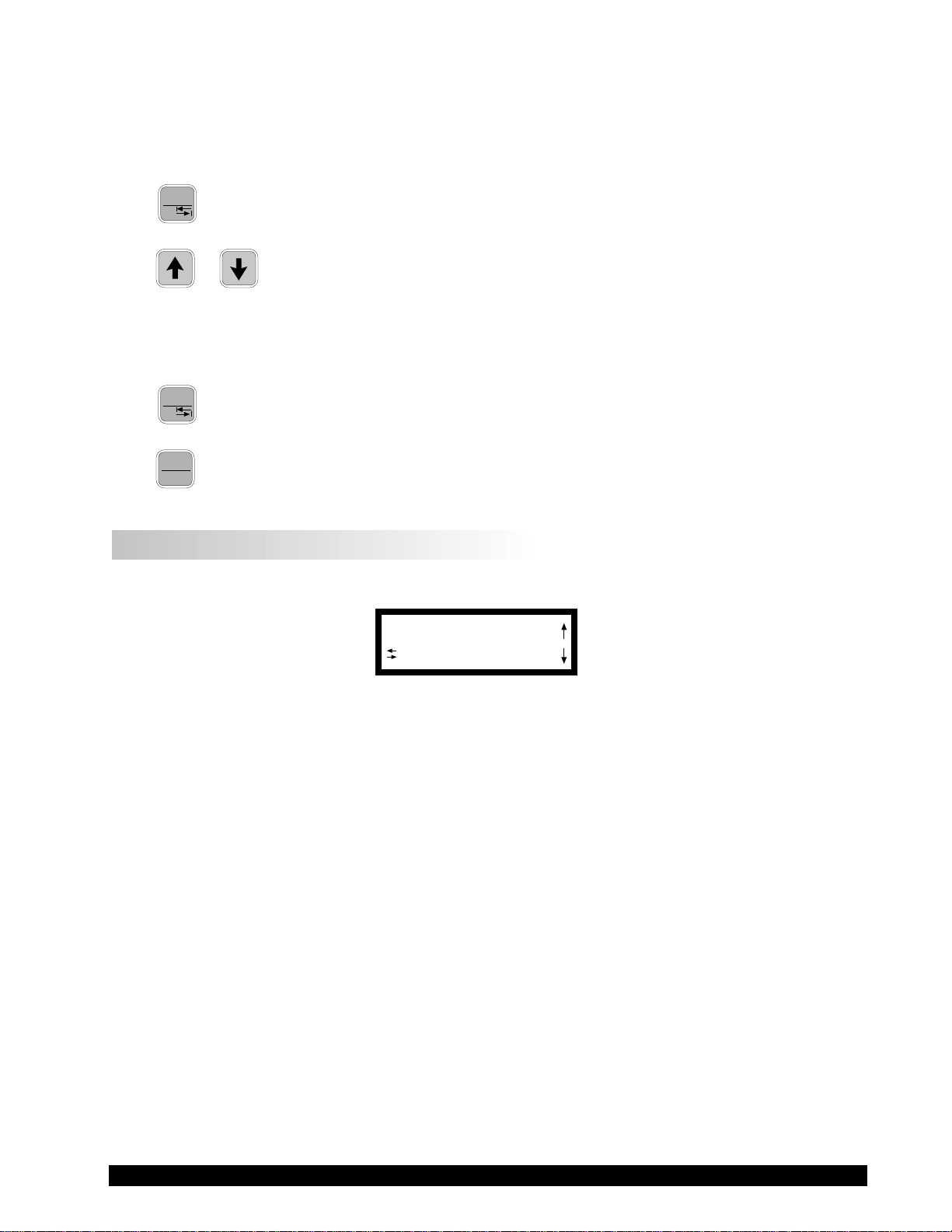

III.2 Setup

From the main Options screen, the user scrolls up or down until the following screen is displayed:

SETUP

TIME TO TORQUE

Figure 24

A press of the ENTER/AUTORANGE key takes you into the Setup sub-menu (Figure 25). As in the

main Options menu, you can scroll up or down through the various Setup options. In order to access

all options, the motor must be turned off.

Brookfield Engineering Labs., Inc. Page 21 Manual No. M/97-164-F1 102

L°F(FAHRENHEIT)

CGS UNITS

L°C(CENTIGRADE)

CGS UNITS

L°F(FAHRENHEIT)

CGS UNITS

LCGS UNITS

SEQUENTIAL

LSEQUENTIAL

PRINT SERIAL

LPRINT SERIAL

DATA AVERAGING

L°F(FAHRENHEIT)

SI UNITS

LCGS UNITS

INTERLEAVE

LSEQUENTIAL

PRINT PARALLEL

OPTIONS

TAB

Figure 25

LCGS UNITS

CUSTOM SPEEDS

III.2.1 Temperature Display

The DV-II+ viscometer can display temperature in either degrees Centigrade or degrees Fahrenheit.

On entry (assuming the viscometer is currently displaying °F) you will be presented with:

L°F(FAHRENHEIT)

CGS UNITS

Figure 26

A press of the OPTIONS/TAB key at this point will “toggle” between the two available temperature

scale options as shown in Figure 27:

L°F(FAHRENHEIT)

CGS UNITS

Figure 27

To select the temperature display mode, press the ENTER/AUTORANGE key. You automatically exit

the Setup menu with the viscometer displaying temperature in the selected scale. You must press the

ENTER/AUTORANGE key to select the flashing option.

III.2.2 Units of Measurement

Selecting units of measurement is identical to that for temperature described above. The screen

display shows:

L°C(CENTIGRADE)

CGS UNITS

Brookfield Engineering Labs., Inc. Page 22 Manual No. M/97-164-F1102

L°F(FAHRENHEIT)

CGS UNITS

Figure 28

A press of the OPTIONS/TAB key at this point allows the user to “toggle” between the two available

data display units as shown in Figure 29:

L°F(FAHRENHEIT)

CGS UNITS

Figure 29

L°F(FAHRENHEIT)

SI UNITS

Pressing the ENTER/AUTORANGE key selects the display units, which are flashing, followed by an

exit of the Setup menu. You must press the ENTER/AUTORANGE key to select the flashing option.

III.2.3 Motor Speed Set Selection

This selection must be done with the motor off. Scrolling in the Setup options menu to the speed set

selection option yields the following screen display:

LCGS UNITS

SEQUENTIAL

Figure 30

The last selected speed set option is displayed, in this case, Sequential. For each press of the

OPTIONS/TAB key, the display shows selectable options (Figure 31). You must press the ENTER/

AUTORANGE key to select the flashing option.

LCGS UNITS

INTERLEAVE

LCGS UNITS

CUSTOM SPEEDS

Figure 31

LCGS UNITS

SEQUENTIAL

The speeds available in each of the above options are listed in Appendix F. The DV-II+ is initially

set up with the Sequential Speed Set at Brookfield prior to shipment.

III.2.3.1 LV/RV Speeds

In the case of Sequential or Interleave, a press of the ENTER/AUTORANGE key immediately selects

that option and exits the SETUP option menu.

Brookfield Engineering Labs., Inc. Page 23 Manual No. M/97-164-F1 102

Loading…

Ротационный вискозиметр Brookfield DV2TRV.

Особенности и преимущества

* 5–дюймовый полноцветный сенсорный дисплей

* Усовершенствованный контроль

* Индикатор измерения в режиме реального времени

* Поддержка нескольких языков интерфейса

Повышенная безопасность

* Настраиваемый доступ пользователя

* Файл фиксации даты и времени анализа

…

Перейти к полному описанию >

Ротационный вискозиметр Brookfield DV2TRV.

Особенности и преимущества

- 5–дюймовый полноцветный сенсорный дисплей

- Усовершенствованный контроль

- Индикатор измерения в режиме реального времени

- Поддержка нескольких языков интерфейса

Повышенная безопасность

- Настраиваемый доступ пользователя

- Файл фиксации даты и времени анализа

- Защищенный паролем доступ

- Мобильные настройки регистрации

Встроенные опции

- Испытания на скорость

- Усреднение данных

- Программируемые пределы контроля качества/аварийные сигналы

- Настраиваемые списки скорости/шпинделя

- Инструкции для пользователя в зависимости от испытания

- Экранное сравнение данных

Отображаемая информация

- Вязкость (сПз или мПа•с)

- Температура (°C или °F)

- Скорость сдвига/напряжение сдвига

- Крутящий момент %

- Скорость вращения/шпиндель

- Статус текущего шага выполнения программы

Программа RheocalcT (дополнительная)

Программа Rheocalc обеспечивает автоматическое управление и сбор данных с использованием компьютера. Rheocalc может анализировать данные, накладывать несколько графиков друг на друга, распечатывать табличные данные, рассчитывать математические модели и выполнять другие экономящие время операции. Можно графически отобразить и сохранить до пяти сравниваемых наборов данных.

Дополнительные функции программы

- Встроенные подсказки, обеспечивающие пошаговое создание стандартных тестов

- Функции с поддержкой циклов для решения повторяющихся задач

- Усреднение собранных данных по шагам или в целом для испытания

- Возможно математическое моделирование: Bingham, Casson, Casson NCA/CMA, Power Law, IPC Paste, Herschel-Bulkley, Thix Index

| Диапазон вязкости, сПз (мПа*с) | Скорости | |||

| Модель | Мин. | Макс. | Об./мин. | Число скоростей |

| DV2TLV | 1** | 6000000 | 0,1 — 200 | 200 |

| DV2TRV | 100 | 40000000 | 0,1 — 200 | 200 |

| DV2THA | 200 | 80000000 | 0,1 — 200 | 200 |

| DV2THB | 800 | 320000000 | 0,1 — 200 | 200 |

** — 1 сПз достигается с UL адаптером, 15 сПз для модели LV со стандартными шпинделями.

- Набор из 6 шпинделей (RV/HA/HB)

- Специализированная программа PG Flash

- Температурный датчик RTD

- Предохранительная подставка для шпинделя

- Лабораторный штатив (модель G)

- Набор инструментов для техобслуживания (флеш-накопитель USB, стилус, салфетка для очистки)

- Кейс для хранения и переноски

- Руководство по эксплуатации

- Гарантийный талон

- Упаковка