-

Страница 1

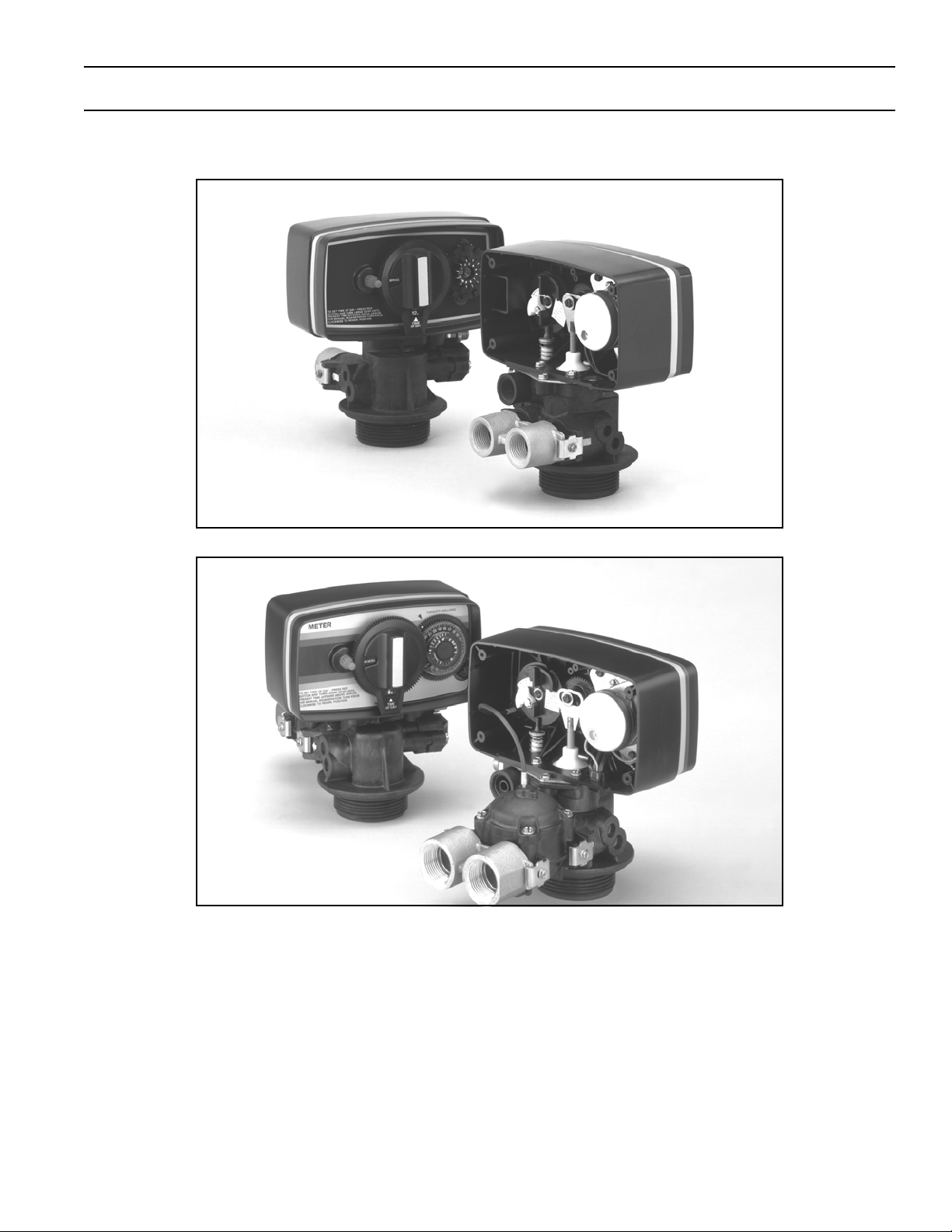

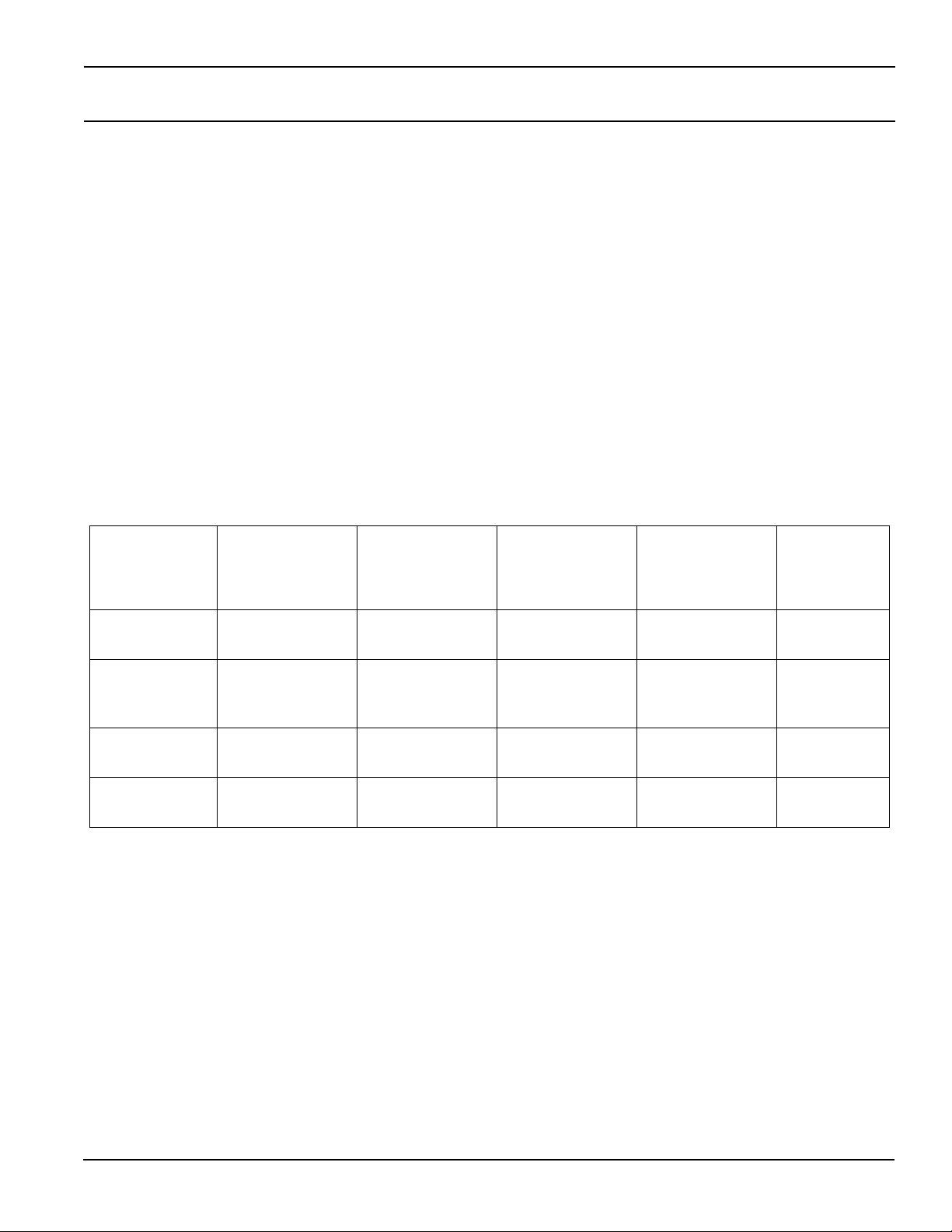

Model 5600 & 5600 Econominder ® Service Manual IMPORTA NT: Fill in p ertinent info rmation on page 3 for future reference.[…]

-

Страница 2

2 Model 5600 & 5600 Econominder ® Table of Contents Job Specification Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 General Residential Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . .[…]

-

Страница 3

Model 5600 & 5600 Econominder ® 3 Job Specification Sheet Job Number _______________ _________________ ___ Model Number __ __________________ ____________ W ater T est _____________ _________________ ______ Capacity of Unit __________ ______________ Max. __ ___________ Per Regeneration Mineral T ank Size: Diameter ____ _______________ Heigh t […]

-

Страница 4

4 Model 5600 & 5600 Econominder ® General Residential Installation Check List W at er Pressur e A minimum of 25 lbs of water pressure is r equ ired for regeneration valve to operate effectively . Electrical Facilities An uninterrupted alternating current (A/C) suppl y is required. Please make sure voltage su pply is compatible with unit before[…]

-

Страница 5

Model 5600 & 5600 Econominder ® 5 Valve Installation and Start-up Procedures 1. Place the softener ta nk where you want to install the unit. NOTE: Be sure the tank is level and on a firm base. 2. During cold weather it is recommended th at the installer warm the valve to room temperature before operatin g. 3. Perform all plumbing according to […]

-

Страница 6

6 Model 5600 & 5600 Econominder ® Model 5600 Installation and Start-up Procedures NOTE: Install the water softener with th e inlet, outlet and drain connections made according to manufacturer’ s recommendations and to m eet applicable plumbing cod es. 1. Manually index the softener control into the In Service position and let water flow into[…]

-

Страница 7

Model 5600 & 5600 Econominder ® 7 Model 5600 Backwash Filter Installation and Start-up Procedures NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’ s recommendations and to meet applicable pl umbing codes. Before Plugging in the Unit 1. Open a treated water tap down stream of the fi[…]

-

Страница 8

8 Model 5600 & 5600 Econominder ® Model 5600 Backwash Filter Installation and Start-up Procedures (Cont’d.) Cycle Times and Flow Diagrams 1. In Service position. See Figure 4, page 10 . 2. Preliminary Rinse position. — Same as Figure 4, page 10 with standard piston (white end plug) or filter piston (black end plug). — Eliminated with low[…]

-

Страница 9

Model 5600 & 5600 Econominder ® 9 Model 5600 Econominder Installation and Start-up Procedures NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’ s recommendations and to meet applicable pl umbing codes. 1. Manually index the softener control to the In Service position and let water f[…]

-

Страница 10

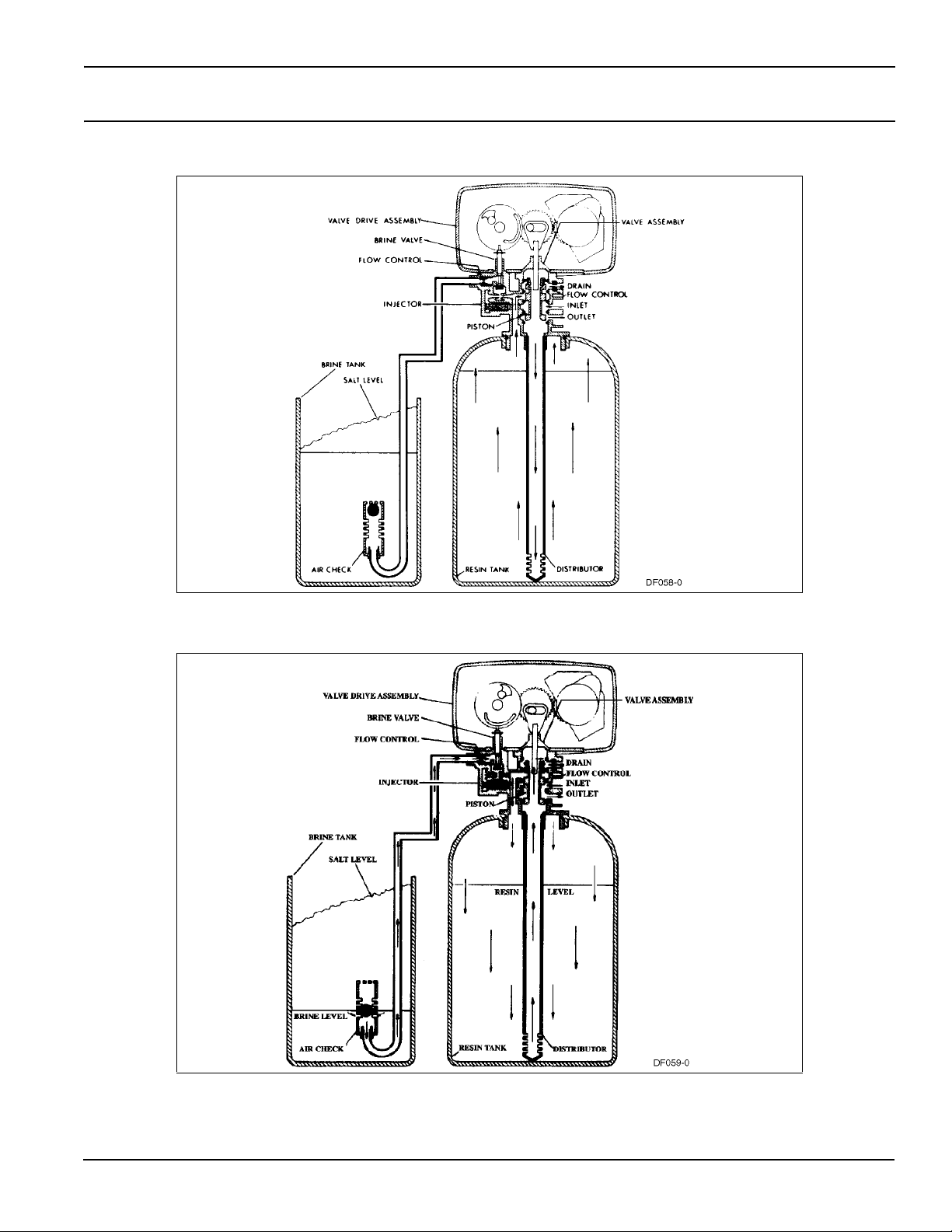

10 Model 5600 & 5600 Econominder ® Water Conditioner Flow Diagrams Service Position Pr eliminary Rinse Position Figur e 4 : Service Position Figur e 5 : Preliminary Rinse Position[…]

-

Страница 11

Model 5600 & 5600 Econominder ® 11 Water Conditioner Flow Diagrams (Cont’d.) Backwash Position Brine Position Figur e 6 : Backwash Position Figur e 7 : Brine Position[…]

-

Страница 12

12 Model 5600 & 5600 Econominder ® Water Conditioner Flow Diagrams (Cont’d.) Slow Rinse Position Second Backwash Position Figur e 8 : Slow Rinse Position Figur e 9 : Second Ba ckwash Position[…]

-

Страница 13

Model 5600 & 5600 Econominder ® 13 Water Conditioner Flow Diagrams (Cont’d.) Settling Rinse Position Brine T ank Fill Position Figure 10 : Settling Rinse Position Figur e 1 1 : Brine T ank Fill Position[…]

-

Страница 14

14 Model 5600 & 5600 Econominder ® Model 5600 Control Valve Drive Assembly Figur e 12 : Model 5600 Control V alve Drive Assembl y 1 29 27 20 16 15 19 22 5 1A 1A 13 14 37 39 12 38 34 21 7 8 6 9 2 3 4 11 26 28 5 30 35 23 5 25[…]

-

Страница 15

Model 5600 & 5600 Econominder ® 15 Model 5600 Control Valve Drive Assembly ▲ Not used when a filter valve Item Number No. Req’d Part Number Description 1 1 14448-010 housing, with pin 1 14448-011 housing, with pin drilled for screw 1 14448-012 housing, with pin drilled for thumb screw 1A 1 15494-01 “L” housing, with pin 1 15494-03 “L[…]

-

Страница 16

16 Model 5600 & 5600 Econominder ® Model 5600 and 5600 Econominder Control Valve Drive Assembly Figure 13 : Model 5600 and 5600 Econominder Control V alve Drive Assembly 48 47 10 49 50 12 11 9 8 2 7 2 3 16 15 1 17 55 20 22 23 21 26 14 53 39 42 43 52 Backwash Filter Injector Option 34 33 32 29 20 30 20 31 27 28 46 18 4 19 42 43 5 22 39 40 38 52[…]

-

Страница 17

Model 5600 & 5600 Econominder ® 17 Model 5600 and 5600 Econominder Control Valve Drive Assembly * not used wi th meter controls ▲ used in backwash fi lter Item Number No. Req’d Part Number Description 1 2-4 13255 adapter clip (c lock or meter) 2 5 13242 seal 5 17772 silicone s eal 3 1 61400-12 valve body asse mbly , 1 ″ dist. 1 61400-11 […]

-

Страница 18

18 Model 5600 & 5600 Econominder ® Model 5600 Econominder Control Valve Drive Assembly Figur e 14 : Model 5600 Econominder Control V alve Drive Assembly 29 1 27 19 20 18 21 1A 13 12 42 14 44 43 34 16 15 7 8 6 9 2 3 4 28 25 5 23 5 11 35 45 30 37 38 40 39 41 22 24[…]

-

Страница 19

Model 5600 & 5600 Econominder ® 19 Model 5600 Econominder Control Valve Drive Assembly Item Number No. Req’d Part Number Description 11 14448-000 housing, with roll pin 1 14488-001 housing, with pin drilled for screw 1 14448-0 housing, with pi n drilled for thumb screw 1A 1 15494-01 “L” housin g, with pin 1 15494-03 “L” housing, w it[…]

-

Страница 20

20 Model 5600 & 5600 Econominder ® Bypass Valve Assembly, Plastic Figur e 15 : Bypass V alve Assembly , Plastic Item Number No. Req’d Part Number Description 9 2 13305 o-ring, 1 19 10 2 13255 clip, mounting 11 2 13314 screw , hex washer head, #8-18 x 5/8 » 12A 1 18706 yoke, plastic 1″ NP T 1 18706-02 yoke, plastic 3/4″ 12B 1 1[…]

-

Страница 21

Model 5600 & 5600 Econominder ® 21 Bypass Valve Assembly, Brass Figur e 16 : Bypass V alve A ssembly , Brass Item Number No. Req’d Part Number Description 1 1 17290 bypass valve body , 3/4″ 1 17290NP bypass valve body , 3/4″) 1 13399 bypass valve body , 1″ 1 13399NP bypass valve body , 1″ (nickel-plated) 2 1 1 1726 seal, […]

-

Страница 22

22 Model 5600 & 5600 Econominder ® Model 5600 Econominder Meter Assembly Figure 17 : Model 5600 Eco nominder Meter Assembly Item Number No. Req’d Part Number Description 1 4 12473 screw , meter cover assembly 2A 1 14038 meter cover assembly , standard 2B 1 15659 meter cover assembly , extended range (right angle) 3 1 13847 o-ring, meter cove[…]

-

Страница 23

Model 5600 & 5600 Econominder ® 23 Service Instructions Replace Time Brine V alve, Injectors and Scr een 1. Unplug electrical cord from outlet. 2. Turn off water supply to conditioner: — If the conditioner installation h as a “three valve” bypass sy st em, first open the valve in the bypass line, then close the valves at the conditioner […]

-

Страница 24

24 Model 5600 & 5600 Econominder ® Service Instructions (Cont’d.) Replace Timer 1. Unplug electrical cord from outlet. 2. Turn off water supply t o conditioner: — If the conditioner i nstallation has a “three valve” bypass system, fi rst open the valve in the bypass l ine, then close the valves at the conditioner inlet and ou tlet. —[…]

-

Страница 25

Model 5600 & 5600 Econominder ® 25 Service Instructions (Cont’d.) Replace Piston Assembly 1. Unplug electrical cord from outlet. 2. Turn off water supply to conditioner: — If the conditioner installation h as a “three valve” bypass sy st em, first open the valve in the bypass line, then close the valves at the conditioner inl et and ou[…]

-

Страница 26

26 Model 5600 & 5600 Econominder ® Service Instructions (Cont’d.) Replace Seals and Spacers 1. Unplug electrical cord from outlet. 2. Turn off water supply t o conditioner: — If the conditioner i nstallation has a “three valve” bypass system, fi rst open the valve in the bypass l ine, then close the valves at the conditioner inlet and […]

-

Страница 27

Model 5600 & 5600 Econominder ® 27 Service Instructions (Cont’d.) Replace Meter 1. Unplug electrical cord from outlet. 2. Turn off water supply to conditioner: — If the conditioner installation h as a “three valve” bypass sy st em, first open the valve in the bypass line, then close the valves at the conditioner inl et and outlet. — […]

-

Страница 28

28 Model 5600 & 5600 Econominder ® Service Instructions (Cont’d.) Replace Meter Cover and/or Impeller 1. Unplug electrical cord from outlet. 2. Turn off water supply to conditioner: — If the conditioner installation h as a “three valve” bypass sy st em, first open the valve in the bypass line, then close the valves at the conditioner i[…]

-

Страница 29

Model 5600 & 5600 Econominder ® 29 Model 5600 and 5600 Econominder Troubleshooting PROBLEM CAUSE CORRECTION 1. Softener fails to regenerate. A. Electrical service to un it has been interrupted. A. Assure permanent electrical service (check fuse, plug, pull chain or switch). B. T imer is defective. B. Replace timer . C. Power failure. C. Reset […]

-

Страница 30

30 Model 5600 & 5600 Econominder ® Model 5600 and 5600 Econominder Troubleshooting (Cont’d.) General Service Hints for Meter Contr ol PROBLEM CAUSE CORRECTION 9. Softener fails to draw brine. A. Draw line flow control is plugged. A. Clean drain line flow control. B. Injector is plugged. B. Clean or replace injectors. C. Injector screen plugg[…]

-

Страница 31

Model 5600 & 5600 Econominder ® 31 Model 5600SF Troubleshooting PROBLEM CAUSE CORRECTION 1. Filter fails to backwash. A. Electrical service to unit has been interrupted. A. Assure permanent electrical service (check fuse, plug, pull chain or switch). B. T imer is defective. B. Replace timer . C. Power failure. C. Reset time of day . 2. Filter […]

-

Страница 32

32 Model 5600 & 5600 Econominder ® Service Assemblies Part Number Description 60102-00 piston, softener 60102-10 piston, filter 60102-20 piston, low water 60125 seal kit 60084-XX injector 60032 brine valve 60514 brine cam, 3-18 60514-01 brine cam, 6-36 60514-02 brine cam, minutes 60510 coupling, with clip and screws 60040 bypass, brass 3/4&quo[…]

-

Страница 33

Model 5600 & 5600 Econominder ® 33 Notes:[…]

-

Страница 34

34 Model 5600 & 5600 Econominder ® Notes:[…]

-

Страница 35

[…]

-

Страница 36

P/N 40106 Rev . H 05/05[…]

Model 5600 & 5600 Econominder

Service Manual

®

IMPORTANT: Fill in pertinent information on page 3 for future reference.

Model 5600 & 5600 Econominder

®

Table of Contents

Job Specification Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Residential Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Valve Installation and Start-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model 5600 Installation and Start-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Model 5600 Backwash Filter Installation and Start-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Model 5600 Econominder Installation and Start-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Conditioner Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Service Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preliminary Rinse Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Backwash Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Brine Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Slow Rinse Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rapid Rinse Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Settling Rinse Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Brine Tank Fill Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Model 5600 Control Valve Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Model 5600 and 5600 Econominder Control Valve Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Model 5600 Econominder Control Valve Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Bypass Valve Assembly, Plastic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bypass Valve Assembly, Brass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Model 5600 Econominder Meter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replace Time Brine Valve, Injectors and Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replace Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replace Piston Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replace Seals and Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Replace Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replace Meter Cover and/or Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Model 5600 and 5600 Econominder Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General Service Hints for Meter Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Model 5600SF Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2

Model 5600 & 5600 Econominder

®

Job Specification Sheet

Job Number ___________________________________

Model Number ________________________________

Water Test ____________________________________

Capacity of Unit ________________________ Max. _____________ Per Regeneration

Mineral Tank Size: Diameter ___________________ Height _____________________

Brine Tank Size and Salt Setting Per Regeneration: ___________________________________

Control Valve Specifications

Type of Timer: ___ Std. ___ «L» ___ 7-day ___ 12-day ___ Meter, Std. ___ Meter, Ext.

Day/Time of Regeneration _____________________________

Drain Line Flow Control _______________________________ gpm

Brine Refill Rate _____________________________________ gpm

Injector Size ________________________________________

Meter Gallon Setting _________________________________ gal

Slow Rinse

Tan k Si ze

(diameter) Injector

6″

7″

8″

9″

10″

12″

13″

14″

16″

NOTE: Due to varying water conditions, tank sizes and water pressures, use the above settings as guidelines only.

1

BLFC (Brine Line Flow Control), refill rate for filling brine tank.

2

DLFC (Drain Line Flow Control), backwash and rapid rinse flow rates.

#0 red

#0 red

#1 white

#1 white

#1 white

#2 blue

#2 blue

#3 yellow

#3 yellow

Rate (gpm)

@ 40 psi

.31 gpm

.31 gpm

.45 gpm

.45 gpm

.45 gpm

.84 gpm

.84 gpm

1.0 gpm

1.0 gpm

Brine Draw

Rate (gpm)

@ 40 psi BLFC

.28 gpm

.28 gpm

.38 gpm

.38 gpm

.38 gpm

.56 gpm

.56 gpm

.63 gpm

.63 gpm

.5 gpm

.5 gpm

.5 gpm

.5 gpm

.5 gpm

1.0 gpm

1.0 gpm

1.0 gpm

1.0 gpm

1

BLFC

1.2 gpm

1.2 gpm

1.5 gpm

2.0 gpm

2.4 gpm

3.5 gpm

4.0 gpm

5.0 gpm

7.0 gpm

2

3

Model 5600 & 5600 Econominder

General Residential Installation Check List

Water Pressure

A minimum of 25 lbs of water pressure is required for regeneration valve to operate effectively.

Electrical Facilities

An uninterrupted alternating current (A/C) supply is required. Please make sure voltage supply is compatible with unit

before installation.

Existing Plumbing

Condition of existing plumbing should be free from lime and iron buildup. Replace piping that has heavy lime and/or iron

build-up. If piping is clogged with iron, install a separate iron filter unit ahead of the water softener.

Location of Softener and Drain

Locate the softener close to a clean working drain and connect according to local plumbing codes.

Bypass Valves

Always provide for the installation of a bypass valve if unit is not equipped with one.

®

CAUTION

• Do not exceed 120 psi water pressure.

• Do not exceed 110°F water temperature.

• Do not subject unit to freezing conditions.

4

Model 5600 & 5600 Econominder

®

Valve Installation and Start-up Procedures

1. Place the softener tank where you want to install the unit.

NOTE: Be sure the tank is level and on a firm base.

2. During cold weather it is recommended that the installer warm the valve to room temperature before operating.

3. Perform all plumbing according to local plumbing codes.

— Use a 1/2″ minimum pipe size for the drain.

— Use a 3/4″ drain line for backwash flow rates that exceed 7 gpm or length that exceeds 20′ (6 m).

4. Cut the 1″ distributor tube (1.050 O.D.) flush with top of each tank.

NOTE: Only use silicone lubricant.

5. Lubricate the distributor o-ring seal and tank o-ring seal. Place the main control valve on tank.

6. Solder joints near the drain must be done before connecting the Drain Line Flow Control fitting (DLFC). Leave at least 6″

(152 mm) between the DLFC and solder joints when soldering pipes that are connected on the DLFC. Failure to do this

could cause interior damage to DLFC.

7. Use only Tef lon tape on the drain fitting.

8. Be sure the floor under the salt storage tank is clean and level.

9. Place approximately 1″ (25 mm) of water above the grid plate. If a grid is not utilized, fill to the top of the air check in the

salt tank. Do not add salt to the brine tank at this time.

10. On units with a bypass, place in Bypass position.

— Turn on the main water supply.

— Open a cold soft water tap nearby and let water run a few minutes or until the system is free of foreign material

(usually solder) resulting from the installation. Close the water tap when water runs clean.

11. Place the bypass in the In Service position and let water flow into the mineral tank. When water flow stops, slowly open

a cold water tap nearby and let water run until air is purged from the unit. Then close tap.

12. Plug the valve into an approved power source. When the valve has power it drives to the In Service position.

5

Model 5600 & 5600 Econominder

®

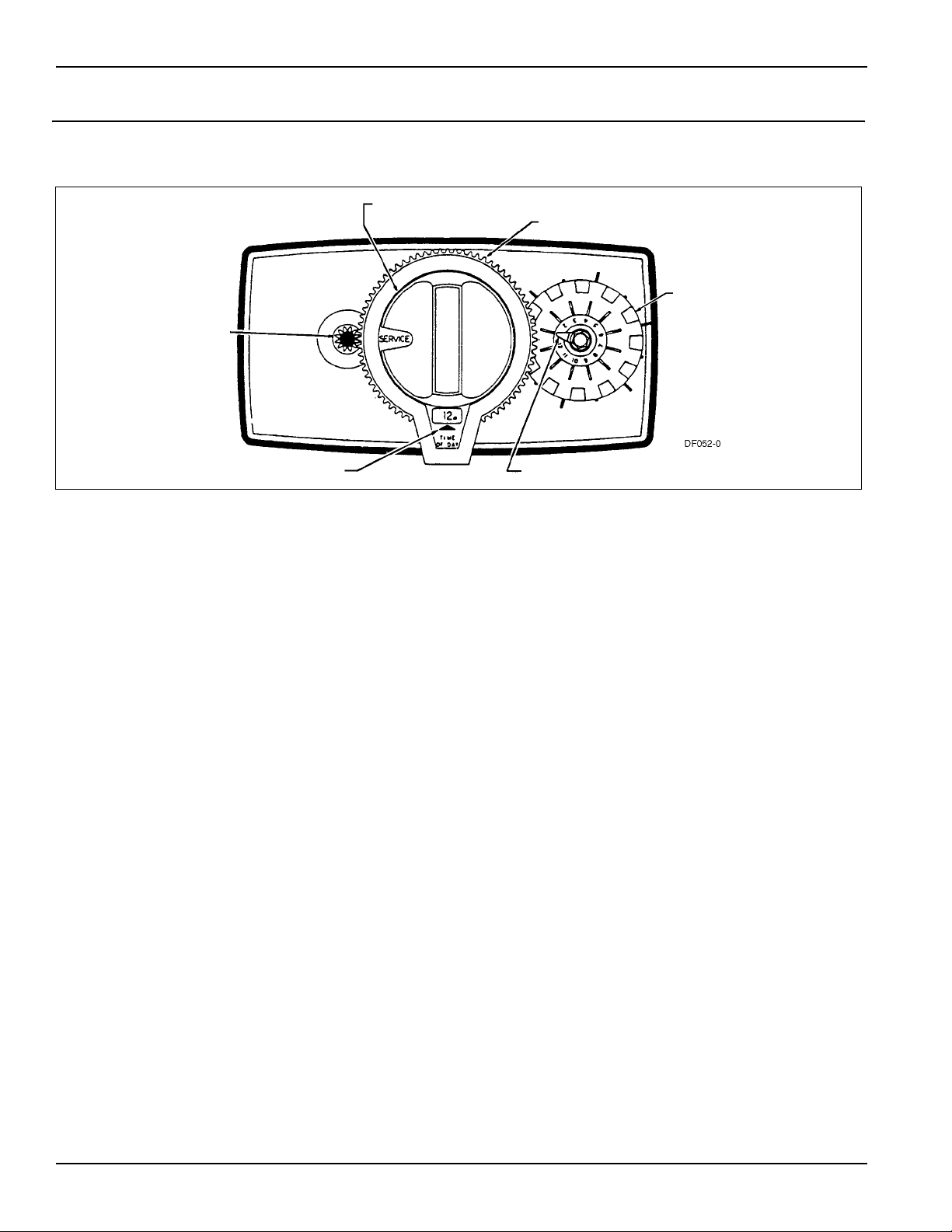

Model 5600 Installation and Start-up Procedures

NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’s

recommendations and to meet applicable plumbing codes.

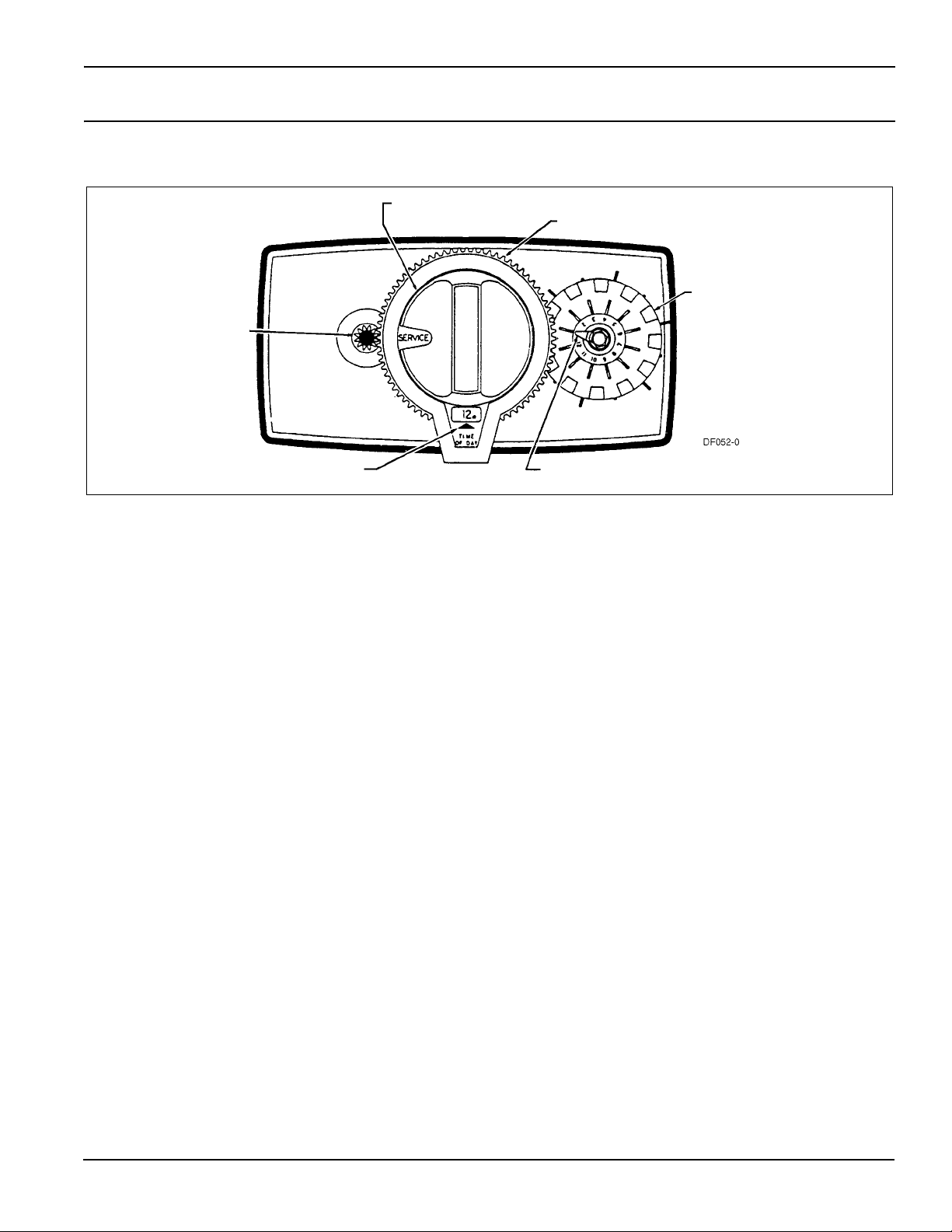

Manual

Red Time

Button

Set

Regeneration Knob

24-Hour Gear

Skipper Wheel

(shows every

other day

regeneration)

Time of Day Arrow

Figure 1: Model 5600 Softener Control

1. Manually index the softener control into the In Service position and let water flow into the resin tank. When the water

flow stops, open a softened water tap until all air is released from the lines. Then close tap.

NOTE: Manually dial the various regeneration positions by turning the knob on the front of the control until the indicator

shows that the softener is in the desired position.

2. Manually index the control to the Backwash position and allow water to flow at the drain for 3 or 4 minutes.

3. Remove back cover plate.

4. Make sure that the salt dosage is set as recommended by the manufacturer. If necessary, set salt according to the setting

instruction sheet. Manually index the control to the Brine Fill position and allow the brine tank to fill to the top of the air

check.

5. Manually index the control to the Brine Draw position and allow the control to draw water from the brine tank until it

stops.

6. Plug in the electrical cord and look in the sight hole in the back of the motor to see that it is running. Set the days that

regeneration is to occur by sliding tabs on skipper wheel outward to expose trip fingers.

— Each tab is one day.

— Finger at red pointer is tonight.

— Moving clockwise from red pointer, extend or retract fingers to obtain the desired regeneration schedule.

7. Manually advance the control to the beginning of the Brine Fill position and allow the control to return to the In Service

position automatically.

8. Fill the brine tank with salt.

9. Replace back cover on the control.

Red Pointer

10. Make sure that any bypass valving is left in the normal In Service position.

6

Model 5600 & 5600 Econominder

®

Model 5600 Backwash Filter Installation and Start-up Procedures

NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’s

recommendations and to meet applicable plumbing codes.

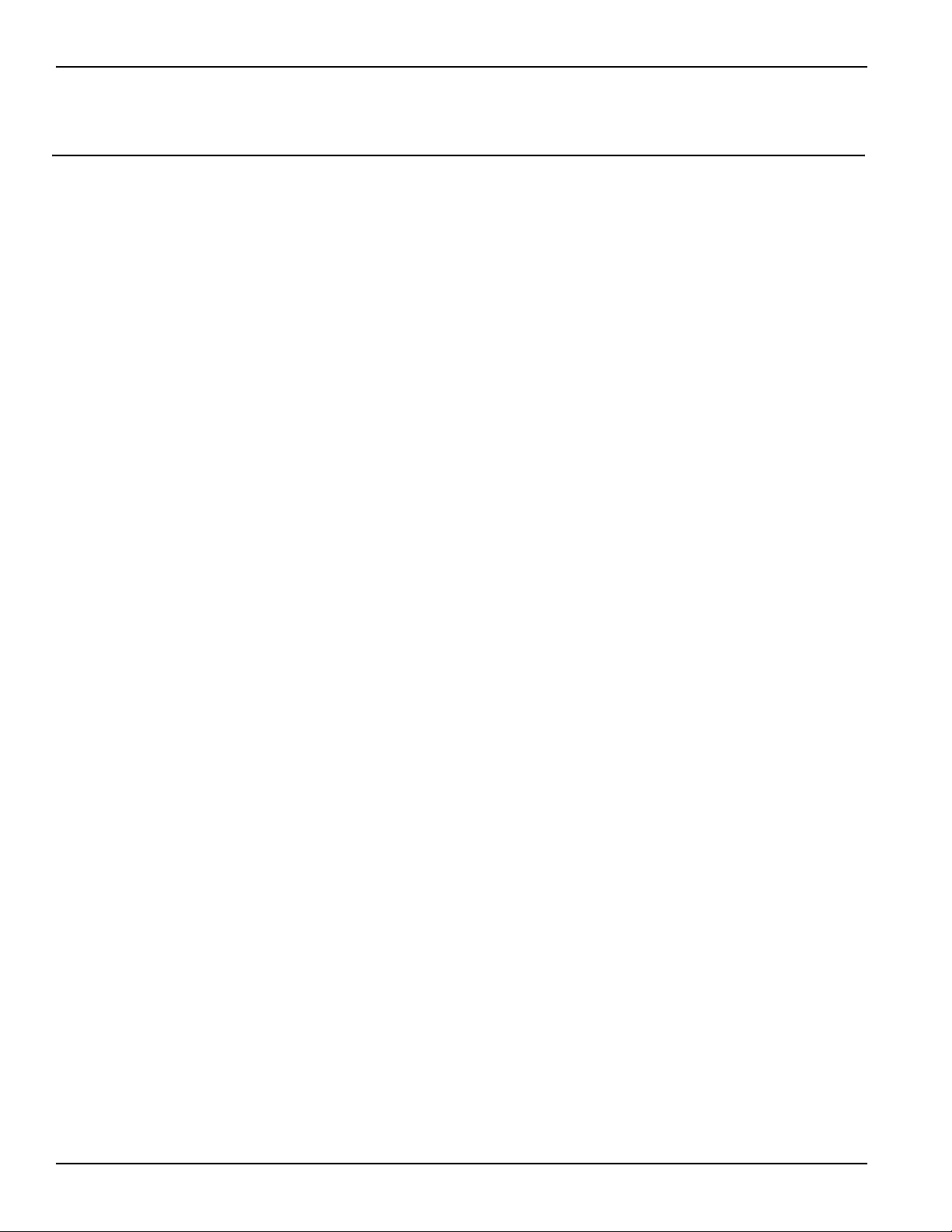

Manual

Red Time

Set

Button

Regeneration Knob

24-Hour Gear

Skipper Wheel

(shows every

other day

backwash)

Time of Day Arrow

Figure 2: Model 5600 Backwash Filter Control

Red Pointer

Before Plugging in the Unit

1. Open a treated water tap down stream of the filter.

2. Manually index the filter to the In Service position and allow the mineral tank to fill by slowly opening the main water

supply valve. Any bypass should be in the In Service position.

NOTE: The water flowing from the downstream tap is cloudy and/or contains media fines as well as air. Allow the water

to run until it appears clean and free of air.

3. When a steady clean flow appears at the tap, close the tap and the main water supply valve and allow the filter media bed

to settle for 15–20 minutes.

4. Manually index the filter to the Backwash position.

5. To prevent a sudden surge of water and air, partially open the main water supply valve so that the flow at the drain of the

filter is approximately 1 gpm. The water at the drain is cloudy again and/or contains media fines as well as air. Allow

water to flow at the drain until it appears clean and free of air.

6. Continue to open the water supply valve until it is completely open. Allow water to flow at the drain until all media fines

are washed out of the filter.

7. Manually index the filter to the In Service position, and again open the downstream tap. Check to be sure that the water

flows clear. If necessary, allow water to flow until all media fines are gone. If the tap is equipped with an aerator check

that is not plugged with media fines and pipe scale.

8. Plug in the electrical cord and look in the sight hole on the back of the timer motor to ensure that it is running. Set the days

backwashing is to occur by sliding tabs on the skipper wheel outward to expose trip fingers. Each tab is one day. Finger at

red pointer is tonight. Moving clockwise from red pointer, extend or retract fingers to obtain the desired backwash

schedule.

9. Set time of day by pushing red button and spin the 24-hour gear until the present time of day is visible above the time of

day arrow.

7

Model 5600 & 5600 Econominder

®

Model 5600 Backwash Filter Installation and Start-up Procedures

(Cont’d.)

Cycle Times and Flow Diagrams

1. In Service position. See Figure 4, page 10.

2. Preliminary Rinse position.

— Same as Figure 4, page 10 with standard piston (white end plug) or filter piston (black end plug).

— Eliminated with low water piston (gray end plug).

3. Backwash position.

— Same as Figure 6, page 11 with standard piston.

— 15 minutes with filter piston.

— 7 minutes with low water piston.

4. Brine Rinse position.

— Eliminated, resulting in a 50 minute pause, no water flows during this time.

5. Slow Rinse position.

— Eliminated, resulting in a 50 minute pause, no water flows during this time.

6. Second Backwash position.

— Same as Figure 9, page 12 with standard piston.

— 15 minutes with filter piston.

— 7 minutes with low water piston.

7. Settling Rinse position.

— Same as Figure 10, page 13 with standard or filter piston.

— Eliminate with low water piston.

8. Brine Tank Refill position.

— Eliminated, filter is back in service at this time.

8

Model 5600 & 5600 Econominder

®

Model 5600 Econominder Installation and Start-up Procedures

NOTE: Install the water softener with the inlet, outlet and drain connections made according to manufacturer’s

recommendations and to meet applicable plumbing codes.

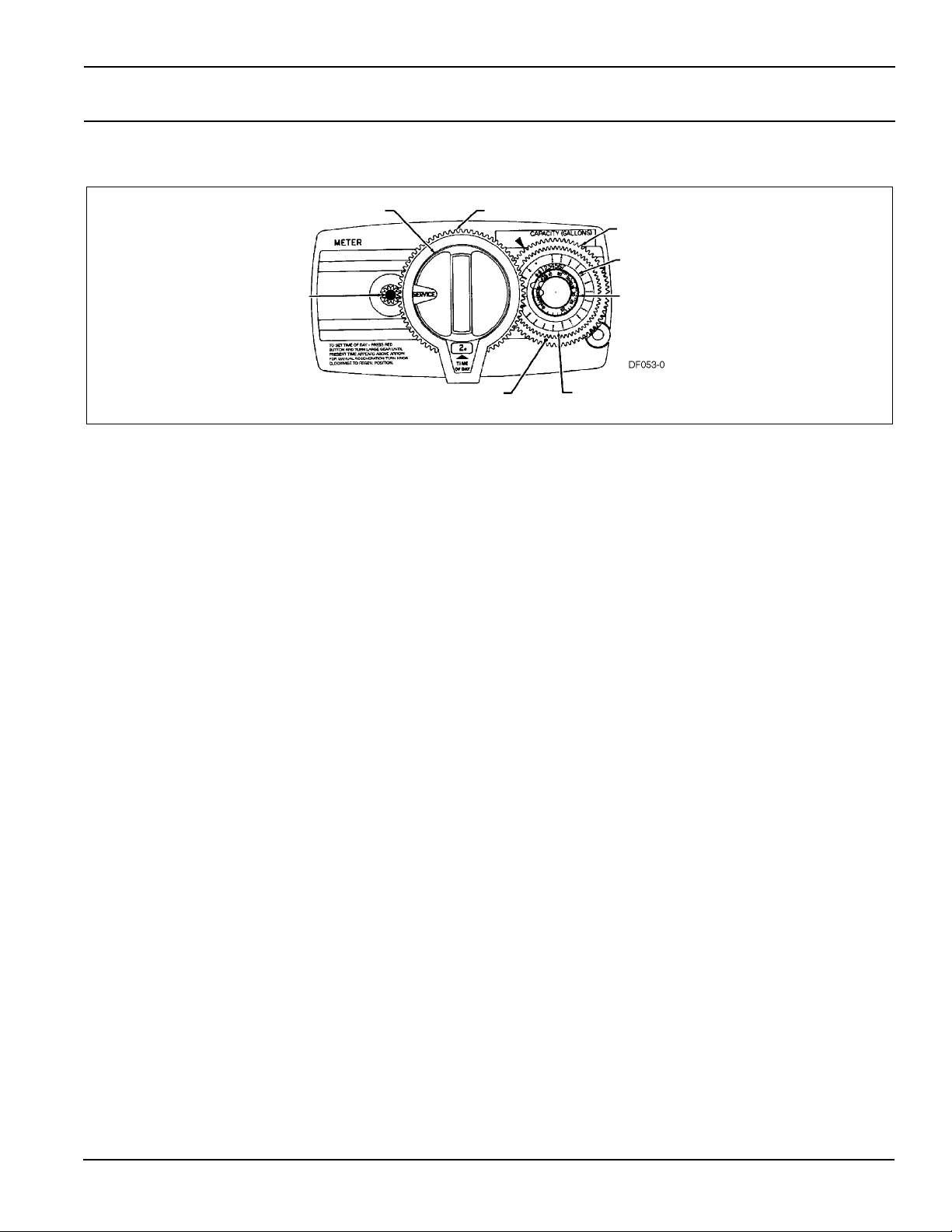

Manual

1. Manually index the softener control to the In Service position and let water flow into the resin tank. When the water flow

stops, open a softened water tap until all air is released from the lines. Then close tap.

NOTE: The various regeneration positions may be dialed manually by turning the knob on the front of the control until

the indicator shows that the softener is in the desired position.

2. Set water usage program wheel using any one of the following procedures:

— Typical Residential Application

To program, just set the time, set the hardness and it automatically monitors system needs and regenerates only when

necessary. To set time of day press red time set button and turn 24-hour gear until present time of day is at “time of

day.” Set program wheel by lifting the “people” dial and rotating it so that the number of people in the household is

aligned with the household grains per gallon water hardness. Release the dial and check for firm engagement at

setting. This method provides reserve capacity based on 75 gallons per person.

— Optional Programming Procedures

Calculate the gallon capacity of the system, subtract the necessary reserve requirement and set the gallons available at

the small white dot on program wheel gear. Note, drawing shows 850 gallon setting. The capacity (gallons) arrow

denotes remaining gallons exclusive of fixed reserve.

Regeneration Knob

Red Time

Set

Button

24-Hour Gear

White Dot

Figure 3: Model 5600 Econominder

Program Wheel

People Dial

Grains Per Gallon

Water Hardness

Scale

Gallons Label

3. Rotate program wheel counterclockwise until it stops at Regeneration position.

4. Manually index the control to the Backwash position and allow water to flow at the drain for 3 or 4 minutes.

5. Remove back cover plate.

6. Make sure than the salt dosage is set as recommended by the manufacturer. Manually index the control to the Brine Fill

position and allow the brine tank to fill to the top of the air check.

7. Manually index the control to the Brine Rinse position and allow the control to draw water from the brine tank until it

stops.

8. Plug in the electrical cord and look in the sight hole in the back of the monitor to see that it is running.

9. Manually advance the control to the beginning of the Brine Fill position and allow the control to return to the In Service

position automatically.

10. Fill the brine tank with salt.

11. Replace back cover on the control. Be sure cable is not pinched between cover and housing.

12. Make sure that any bypass valving is left in the normal In Service position.

9

Model 5600 & 5600 Econominder

Water Conditioner Flow Diagrams

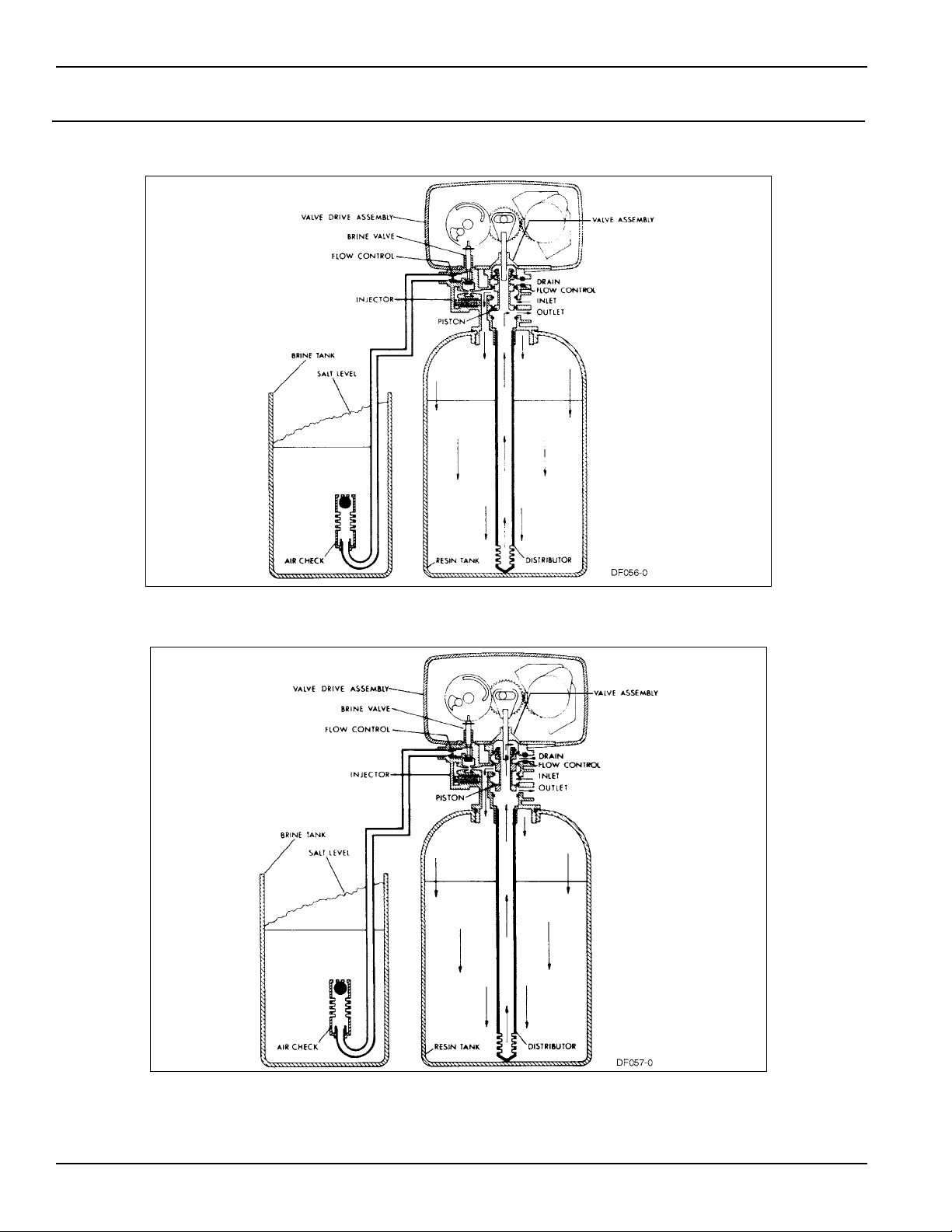

Service Position

®

Preliminary Rinse Position

Figure 4: Service Position

10

Figure 5: Preliminary Rinse Position

Model 5600 & 5600 Econominder

Water Conditioner Flow Diagrams (Cont’d.)

Backwash Position

®

Brine Position

Figure 6: Backwash Position

Figure 7: Brine Position

11

Loading…

Скачать файл PDF «Pentair Water Pool and Spa Water Dispenser Model 5600 & 5600 Econominder Инструкция по эксплуатации» (1.26 Mb)

Популярность:

8237 просмотры

Подсчет страниц:

36 страницы

Тип файла:

Размер файла:

1.26 Mb

Google Ads:

- Главная

-

Pentair

-

Фильтры для плавательного бассейна

-

AquaTech

На этой странице вы найдёте полный список документов на Фильтры для плавательного бассейна Pentair AquaTech.

Выберите необходимый PDF файл.

-

Фильтры для плавательного бассейна

Pentair AquaTech Инструкция по эксплуатацииТип файла

PDFРазмер

99 KbКол-во страниц

4Просмотров

1602Download / Read online

- 1

Другие Pentair Фильтры для плавательного бассейна

-

Pentair D.E. Cartridge Style Filter Инструкция по эксплуатации

PDF файлов

1Просмотров

3450 -

Pentair D.E. Cartridge Style Filter Quad D.E. Инструкция по эксплуатации

PDF файлов

1Просмотров

3227 -

Pentair FNS Plus Инструкция по эксплуатации

PDF файлов

1Просмотров

2602 -

Pentair System 3 S8M600 Инструкция по эксплуатации

PDF файлов

1Просмотров

2534 -

Pentair AquaTech Инструкция по эксплуатации

PDF файлов

1Просмотров

2210 -

Pentair Filter CFW Series Инструкция по эксплуатации

PDF файлов

1Просмотров

1969

Другие устройства Pentair

-

Автомобильные видеосистемы

Pentair Intellitouch ScreenLogic Инструкция по эксплуатацииPDF файлов

1Просмотров

15441 -

Сетевые карты

Pentair Pool and Spa Control System SunTouch Инструкция по эксплуатацииPDF файлов

1Просмотров

13530 -

Гидромассажные ванны

Pentair Pool & Spa Heaters NT Series Инструкция по эксплуатацииPDF файлов

1Просмотров

11478 -

Нагреватель воды для бассейна

Pentair MiniMax 200 Инструкция по эксплуатацииPDF файлов

1Просмотров

11103 -

Вакуумные пылесосы для плавательного бассейна

Pentair GreatWhite Automatic Pool Cleaner Инструкция по эксплуатацииPDF файлов

1Просмотров

10932 -

Диспенсеры для воды (Кулеры для воды)

Pentair Water Pool and Spa Water Dispenser Model 5600 & 5600 Econominder Инструкция по эксплуатацииPDF файлов

1Просмотров

9474

Ранее вы смотрели

Производители

ADC

Alliance Laundry Systems

Blodgett

Farenheit Technologies

Intec

Olivetti

Simplicity

Topcom

TrueAir

TV Guide On Screen

Типы устройств

Видеокамеры

Интерфейсы ввода-вывода

Жерновые кофемолки

Лифтовое оборудование

Бурение

Теплицы и расходные материалы для них

Тиски и струбцины

Лампочки индикаторы

Замки

Продукт домашнего изготовления

Устройства

Cisco Systems E-1 6911

Keating Of Chicago Miraclean 2724

Kenmore elite 2709

KitchenAid KPEC992MSS1

Linear DMC1PACK/ Music/ Communication System Package

Makita JRl80DWB

Miller Electric Big Blue 251D

Pioneer DV-PT100

Socket Mobile Series 7

Speco Technologies SP-6AWD/T-W

freeuserguide.ru

About Us

Contacts

Disclamers

Privacy Policy

Эта страница полезна для вас? Поделитесь ссылкой:

- Topics

- manualsbase, manuals,

- Collection

- manuals_contributions; manuals; additional_collections

- Language

- English

- Item Size

- 13.6M

- Addeddate

- 2020-08-17 09:03:34

- Identifier

- manualsbase-id-545220

- Identifier-ark

- ark:/13960/t6066pv08

- Ocr

- ABBYY FineReader 11.0 (Extended OCR)

- Page_number_confidence

- 94.29

- Ppi

- 300

- Scanner

- Internet Archive Python library 1.9.4

plus-circle Add Review

plus-circle Add Review

comment

Reviews

There are no reviews yet. Be the first one to

write a review.

87

Views

DOWNLOAD OPTIONS

download 1 file

ABBYY GZ download

Temporarily Unavailable

DAISY

For users with print-disabilities

Temporarily Unavailable

EPUB

download 1 file

FULL TEXT download

download 1 file

ITEM TILE download

download 1 file

PAGE NUMBERS JSON download

download 1 file

PDF download

download 1 file

SINGLE PAGE PROCESSED JP2 ZIP download

download 1 file

TORRENT download

download 12 Files

download 6 Original

SHOW ALL

IN COLLECTIONS

Manuals: Contributions Inbox

The Manual Library

Additional Collections

Uploaded by

chris85

on