MANITOU AMERICAS, INC.

One Gehl Way

P. O. Box 179

West Bend, WI 53095-0179 U.S.A

Website: www.us.manitou.com

For parts orders contact your Manitou dealer or call:

Manitou Americas Parts Department. 262-334-6653

Fax (254) 867—6504

MLT735 120 LSU

S6-E3

Operator Manual

Catalog No. 51900002

In. Rel. 04-2011

THIS OPERATOR’S MANUAL MUST BE KEPT IN THE LIFT TRUCK AND MUST BE READ AND UNDERSTOOD

BY OPERATORS.

0 — ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS

1 — OPERATING & SAFETY INSTRUCTION

2 — DESCRIPTION

3 — MAINTENANCE

4 — ATTACHMENT ENGAGEMENT

5 — ELECTRICAL & HYDRAULIC SCHEMATIC

RELEASE: 04/11

Initial Release

THE TEXTS AND ILLUSTRATIONS IN THIS DOCUMENT MUST NOT BE REPRODUCED EITHER WHOLLY OR IN PART.

ROUGH TERRAIN FORKLIFT TRUCK

GENERAL SAFETY STANDARDS

I

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS

STUDY THE OPERATOR/SERVICE MANUALS

The information in this manual provides general instructions for the safe operation and maintenance of your

forklift truck. This information is vital and must be clearly understood by the operator and serviceman. Study

this manual and the Rough Terrain Forklift Safety Manual (part no. 422494) thoroughly and carefully before

operating or servicing your forklift. Contact your dealer or Manitou North America, Inc. if you have any questions concerning your forklift, its operation, service or parts. Keep both manuals in the literature box on the

forklift available for reference. If either manual becomes illegible or is missing, contact your dealer for replacements immediately. This manual cannot cover every situation that might result in an accident. It is the responsibility of the operator to always remain alert for potential hazards and be prepared to avoid them!

ADDITIONAL RECOMMENDED LITERATURE:

ANSI / ITSDF B56.6 is the national consensus standard for rough terrain forklift trucks. It contains rules about

forklift safety, maintenance, safe operation, training, and supervision. Forklift owners should learn this standard and make it available for their operators, service personnel, and supervisors. These standards can be

obtained, free of charge, from the Industrial Truck Standards Development Foundation (ITSDF) on their website at www.itsdf.org. The following references are examples from the standard, addressing forklift operators:

A.) OPERATOR TRAINING QUALIFICATIONS

1.) The user shall ensure that operators understand that safe operation is the operator’s responsibility. The

user shall ensure that operators are knowledgeable of, and observe, all safety rules and practices.

2.) Create an effective operator training program centered around user company’s policies, operating conditions, and rough terrain forklift trucks. The program should be presented completely to all new operators and

not be condensed for those claiming previous experience.

3.) Information on operator training is available from several sources, including rough terrain forklift truck manufacturers, users, government agencies, etc.

4.) An operator training program should consist of the following:

a.) careful selection of the operator, considering physical qualifications, job attitude, and aptitude;

b.) emphasis on safety of stock, equipment, operator, and other personnel;

c.) citing of rules and why they were formulated;

d.) basic fundamentals of rough terrain forklift truck and component design as related to safety, e.g.,

in.-lb (N-m) loading, mechanical limitations, center of gravity, stability, etc.;

e.) introduction to equipment, control locations, and functions. Explain how they work when used

properly and problems when used improperly.

f.) supervise practice on operating course remote from normal activity and designed to simulate

actual operations, e.g., lumber stacking, elevating shingles to the roof, etc.;

g.) oral, written, and operational performance tests and evaluations during and at completion of the

course;

h.) refresher courses, which may be condensed versions of the primary

course, and periodic “on job” operator evaluation;

i.) understanding of nameplate data and operator instructions and warning information appearing on

the rough terrain forklift truck.

B.) GENERAL SAFETY PRACTICES

1.) Rough terrain forklift trucks can cause injury if improperly used or maintained.

2.) Only authorized operators trained to adhere strictly to all operating instructions shall be permitted to oper-

ate rough terrain forklift trucks. Unusual operating conditions may require additional safety precautions, training, and special operating instructions.

3.) Modifications and additions which affect capacity or safe operation shall not be preformed without the man-

ufacturer’s prior written approval. Where such authorization is granted, capacity, operation, and maintenance

instruction plates, tags, or decals shall be changed accordingly.

4.) If the rough terrain forklift truck is equipped with front end attachment(s) or optional forks, the user shall see

that the truck is marked to identify the forks or attachment(s), show the approximate weight of the truck and

fork or attachment combination, and show the capacity of the truck with forks or attachment(s) at maximum

elevation with load laterally centered.

5.) The user shall see that all nameplates and caution and instruction markings are in place and legible.

6.) The user shall consider that changes in load dimension may affect rough terrain forklift truck capacity.

II

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

B.) GENERAL SAFETY PRACTICES (cont.)

7.) Where steering can be accomplished with either hand and the steering mechanism is of a type that pre-

vents road reactions from causing the handwheel to spin (power steering or equivalent), steering knobs may

be used. When used, steering knobs shall be of a type that can be engaged by the operator’s hand from the

top and shall be within the periphery of the steering handwheel.

8.) Experience has shown that rough terrain forklift trucks which comply with stability requirements are stable

when properly operated. However, improper operation, faulty maintenance, or poor housekeeping may contribute to a condition of instability and defeat the purpose of the requirements.

9.) Users shall give consideration to special operating conditions. The amount of forward and rearward tilt to

be used is governed by the application. Although the use of maximum rearward tilt is allowable under certain

conditions, such as traveling with the load lowered, the stability of a rough terrain forklift truck as determined

by standardized tests does not encompass consideration for excessive tilt at high elevations or the operation

of trucks with excessive off-center loads.

10.) Some of the conditions which may affect stability are ground and floor conditions, grade, speed, loading

(rough terrain forklift trucks equipped with attachments behave as partially loaded trucks even when operated

without a load on the attachment), dynamic and static forces, improper tire inflation, and the judgement exercised by the operator.

C.) OPERATING SAFETY RULES AND PRACTICES

1.) Safe operation is the responsibility of the operator.

2.) This equipment can be dangerous if not used properly . The operator shall develop safe working habits and

also be aware of hazardous conditions in order to protect himself, other personnel, the rough terrain forklift

truck, and other material.

3.) The operator shall be familiar with the operation and function of all controls and instruments before under-

taking to operate the rough terrain forklift truck.

4.) Before operating any rough terrain forklift truck, truck operators shall have read and be familiar with the

operator’s manual for the particular truck being operated.

5.) Before starting to operate the rough terrain forklift truck:

a.) be in operating position and fasten seat belt;

b.) place directional controls in neutral;

c.) apply brakes;

d.) start engine.

6.) Do not start or operate the rough terrain forklift truck, any of its functions, or attachments from any place

other than the designated operator’s position.

7.) Keep hands and feet inside the operator’s designated area or compartment. Do not put any part of the

body outside the operator compartment of the rough terrain forklift truck.

8.) Never put any part of the body into the mast structure or between the mast and the rough terrain forklift

truck.

9.) Never put any part of the body within the reach mechanism of the rough terrain forklift truck or other attach-

ments.

10.) Understand rough terrain forklift limitations and operate the truck in a safe manner so as not to cause injury

to personnel.

1 1.) Do not allow anyone to stand or pass under the elevated portion of any rough terrain forklift truck, whether

empty or loaded.

12.) Do not permit passengers to ride on rough terrain forklift trucks.

13.) Check clearance carefully before driving under electrical lines, bridges, etc.

14.) A rough terrain forklift truck is attended when the operator is less than 25 ft (7.6m) from the truck, which

remains in his view.

15.) A rough terrain forklift truck is unattended when the operator is 25ft (7.6m) or more from the truck, which

remains in his view, or whenever the operator leaves the truck and it is not in his view.

16.) Before leaving the operator’s position:

a.) bring rough terrain forklift truck to a complete stop;

b.) place directional controls in neutral;

c.) apply the parking brake;

d.) lower load-engaging means fully, unless supporting an occupied elevated platform;

e.) stop the engine;

f.) if the rough terrain forklift truck must be left on an incline, block the wheels;

g.) fully lower the load-engaging means.

17.) Maintain a safe distance from the edge of ramps, platforms, and other similar working surfaces.

18.) Do no move railroad cars or trailer with a rough terrain forklift truck.

III

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

C.) OPERATING SAFETY RULES AND PRACTICES (cont.)

19.) Do not use a rough terrain forklift truck for opening or closing railroad car doors.

20.) In areas classified as hazardous, use only rough terrain forklift trucks approved for use in those areas.

21.) Report all accidents involving personnel, building structures, and equipment to the supervisor or as

directed.

22.) Do not add to, or modify, the rough terrain forklift truck.

23.) Do not block access to fire aisles, stairways, and fire equipment.

24.) For rough terrain forklift trucks equipped with a differential lock, the lock should not be engaged when driv-

ing on the road or at high speeds or when turning. If the lock is engaged when turning, there could be loss of

steering control.

25.) Observe all traffic regulations including authorized speed limits. Under normal traffic conditions, keep to

the right, maintain a safe distance, based on speed of travel, from the truck ahead; and keep the truck under

control at all times.

26.) Yield the right-of-way to pedestrians and emergency vehicles such as ambulances and fire trucks.

27.) Do not pass another truck traveling in the same direction at intersections, blind spots, or at other danger-

ous locations.

28.) Slow down and sound the audible warning device(s) at cross-aisles and other locations where vision is

obstructed.

29.) Cross railroad tracks at an angle wherever possible. Do not park closer than 6 ft (1.8m) to the nearest rail

of a railroad track.

30.) Keep a clear view of the path of travel and observe other traffic, personnel, and safe clearances.

31.) If the load being carried obstructs forward view, travel with the load trailing.

32.) Ascend or descend grades slowly and with caution.

a.) When ascending or descending grades in excess of 5%, loaded rough terrain forklift trucks

should be driven with the load upgrade.

b.) Unloaded rough terrain forklift trucks should be operated on all grades with the load-engaging

means downgrade.

c.) On all grades, the load and load-engaging means shall be tilted back, if applicable, and raised

only as far as necessary to clear the road surface.

d.) Avoid turning, if possible, and use extreme caution on grades, ramps, or inclines; normally

travel straight up or down.

33.) Under all travel conditions, operate the rough terrain forklift truck at a speed that will permit it to be brought

to a stop in a safe manner.

34.) Travel with load-engaging means or load low and, where possible, tilted back. Do not elevate the load

except during stacking.

35.) Make starts, stops, turns, or direction reversals in a smooth manner so as not to shift load and/or overturn

the rough terrain forklift truck.

36.) Do not indulge in stunt driving or horseplay.

37.) Slow down for wet and slippery surfaces.

38.) Before driving over a dockboard or bridge plate, be sure that it is properly secured. Drive carefully and

slowly across the dockboard or bridge plate, and never exceed its rated capacity.

39.) Do not drive rough terrain forklift trucks onto any elevator unless specifically authorized to do so.

Approach elevators slowly, and then enter squarely after the elevator car is properly leveled. Once on the elevator, neutralize the controls, shut off engine, and set brakes. It is advisable that all other personnel leave the

elevator before truck is allowed to enter or leave.

40.) Avoid running over loose objects on the roadway surface.

41.) When negotiating turns, reduce speed to a safe level, and turn steering handwheel in a smooth sweeping

motion. Except when maneuvering at a very low speed, turn the steering handwheel at a moderate, even rate.

42.) Use special care when traveling without load, as the risk of lateral overturning is greater.

43.) Improper use of stabilizer controls (if so equipped) could cause rough terrain forklift truck upset. Always

lower the carriage before operating stabilizer controls.

44.) For rough terrain forklift trucks equipped with lateral leveling:

a.) Always level the frame before raising the boom or mast, with or without a load.

b.) Lateral leveling should not be used to position an elevated load; instead, lower the load and

reposition the rough terrain forklift truck.

45.) Handle only stable or safely arranged loads.

a.) When handling off-center loads which cannot be centered, operate with extra caution.

b.) Handle only loads within the capacity of the rough terrain forklift truck.

c.) Handle loads exceeding the dimensions used to establish rough terrain forklift truck capacity

with extra caution. Stability and maneuverability may be adversely affected.

IV

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

C.) OPERATING SAFETY RULES AND PRACTICES (cont.)

46.) When attachments are used, extra care shall be taken in securing, manipulating, positioning, and trans-

porting the load. Operate rough terrain forklift trucks equipped with attachments as partially loaded trucks

when not handling a load.

47.) Completely engage the load with the load-engaging means. Fork length should be at least two-thirds of

load length. Where tilt is provided, carefully tilt the load backward to stabilize the load. Caution should be used

in tilting backward with high or segmented loads.

48.) Use extreme care when tilting load forward or backward, particularly when high tiering. Do not tilt forward

with load-engaging means elevated except to pick up or deposit a load over a rack or stack. When stacking

or tiering, use only enough backward tilt to stabilize the load.

49.) The handling of suspended loads by means of a crane arm (boom) or other device can introduce dynam-

ic forces affecting the stability of a rough terrain forklift truck. Grades and sudden starts, stops, and turns can

cause the load to swing and create a hazard if not externally stabilized. When handling suspended loads:

a.) do not exceed the truck manufacturer’s capacity of the rough terrain forklift truck as equipped

for handling suspended loads.

b.) only lift the load vertically and never drag it horizontally;

c.) transport the load with the bottom of the load and the mast as low as possible;

d.) with load elevated, maneuver the rough terrain forklift truck slowly and cautiously, and only to

the extent necessary to permit lowering to the transport position;

e.) use tag lines to restrain load swing whenever possible.

50.) At the beginning of each shift and before operating the rough terrain forklift truck, check its condition,

giving special attention to:

a.) tires and their inflation pressure

b.) warning devices

c.) lights

d.) lift and tilt systems, load-engaging means, chains, cables, and limit switches

e.) brakes

f.) steering mechanism

g.) fuel system(s)

51.) If the rough terrain forklift truck is found to be in need of repair or in any way unsafe, or if it contributes to

an unsafe condition, the matter shall be reported immediately to the user’s designated authority, and the truck

shall not be operated until it has been restored to safe operating condition.

52.) If during operation the rough terrain forklift truck becomes unsafe in any way, the matter shall be reported

immediately to the user’s designated authority, and the truck shall not be operated until it has been restored to

safe operating condition.

53.) Do not make repairs or adjustments unless specifically authorized to do so.

54.) When refueling, smoking in the area shall not be permitted, the engine shall be stopped, and the opera-

tor shall not be on the rough terrain forklift

truck.

55.) Spillage of oil or fuel shall be carefully and completely absorbed or evaporated and fuel tank cap replaced

before restarting engine.

56.) Do not use open flames when checking electrolyte level in storage batteries, liquid level in fuel tanks, or

the condition of LPG fuel lines and connectors.

57.) Do not lift personnel with the forklift. If the forklift must be used to lift people, precautions for the protec-

tion of the personnel must be taken (see ITSDF B56.6, chapter 5.15 Elevating Personnel).

V

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

D.) SUSPENDED LOADS

A jib or truss boom should ONLY be used to lift and place loads when the machine is stationary and the frame

is level. Transporting suspended loads must ALWAYS be done slowly and cautiously, with the boom and load

as low as possible. Use taglines to restrict loads from swinging, to avoid overturn.

The handling of suspended loads by means of a truss boom or other similar device can introduce dynamic

forces affecting the stability of the machine that are not considered in the stability criteria of industry test

standards. Grades and sudden starts, stops and turns can cause the load to swing and create a hazard.

Guidelines for “Free Rigging / Suspended Loads”

1. DO NOT exceed the rated capacity of the telescopic handler as equipped for handling suspended

loads. The weight of the rigging must be included as part of the load.

2. During transport, DO NOT raise the load more than 12 inches (305 mm) above the ground, or raise

the boom more than 45 degrees.

3. Only lift the load vertically – NEVER drag it horizontally.

4. Use multiple pickup points on the load when possible. Use taglines to restrain the load from swinging

and rotating.

5. Start, travel, turn and stop SLOWLY to prevent the load from swinging. DO NOT exceed walking

speed.

6. Inspect rigging before use. Rigging must be in good condition and in the U.S. comply with OSHA

regulation §1910.184, “Slings,” or §1926.251, “Rigging equipment for material handling.”

7. Rigging equipment attached to the forks must be secured such that it cannot move either sideways or

fore and aft. The load center must not exceed 24 inches (610 mm).

8. DO NOT lift the load with anyone on the load, rigging or lift equipment, and NEVER lift the load over

personnel.

9. Beware of the wind, which can cause suspended loads to swing, even with taglines.

10. DO NOT attempt to use frame-leveling to compensate for load swing.

WARNING

U.S. OSHA regulations effective November 8, 2010 (29 CFR Part 1926, Subpart CC — Cranes and Derricks in

Construction) include requirements for employers that use powered industrial trucks («forklifts») configured

to hoist (by means of a winch or hook) and move suspended loads horizontally. In par ticular, this regulation

applies to any rough-terrain forklift (e.g., «telescopic handler») equipped with a jib or truss boom with a

hook (with or without a winch), or a hook assembly attached to the forks. [Note: This regulation is in

addition to the OSHA regulation that requires specific forklift operator training: §1910.178(l).]

When a forklift / telescopic handler is configured and used for hoisting, the employer must ensure that:

1. Forklift, lift equipment and rigging have been inspected (each shift, month and year) and are in

good, safe condition and properly installed.

2. An operator’s manual and applicable load charts are on the forklift.

3. Work zone ground conditions can support the equipment and load. Any hazardous conditions in the

work area have been identified, and the operator notified.

4. Equipment is being used within its rated capacity and in accordance with the manufacturer’s

instructions.

VI

5. Operator and crew members have been trained in the safe use and operation of the equipment,

including how to avoid electrocution.

6. During use, no part of the equipment, load line or load will be within the minimum clearance

distance specified by OSHA [10 feet (3.0 m), and more for lines rated over 50 kV] of any energized

power line, and any taglines used are non-conductive.

7. In addition, for lift equipment with a rated capacity greater than 2000 lbs. (907 kg), the employer

must ensure that:

a.) An accessible fire extinguisher is on the forklift;

b.) Monthly and annual inspections are performed and documented, and records retained (three

months for monthly, one year for annual);

c.) Before November 10, 2014, operators must have had the additional training and qualification /

certification required by OSHA regulations §1926.1427 and §1926.1430.

Note: Refer to the full text of the OSHA crane regulation (29 CFR Part 1926, Subpart CC) for a detailed

description

VII

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

CONCLUSION:

1.) ATTEND OPERATOR TRAINING CLASSES

The forklift operator must clearly understand all instructions concerning the safe operation of the forklift and all

safety rules and regulations of the work site. They must have successfully completed a training coarse in

accordance with the Powered Industrial Truck Standard (29 CFR 1910.178) as described by the Occupational

Safety and Health Administration (OSHA). They must be qualified as to their visual, hearing, physical, and

mental ability to operate the equipment safely. NEVER use drugs or alcohol while operating a forklift! NEVER

operate or allow anyone to operate a forklift when mental alertness or coordination is impaired! An operator

on prescription or over-the-counter drugs must consult a medical professional regarding any side effects of the

medication that may impair their ability to safely operate the forklift.

2.) CREATE A MAINTENANCE PROGRAM

OSHA recommends a maintenance log, listing repairs requested and completed, for each forklift. Also, “lock

out tag procedures” should be utilized. If the forklift malfunctions; park it safely, remove the key, tag “Do Not

Use”, and report the problem to the proper authority or authorized service personnel immediately.

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS (cont.)

2.) CREATE A MAINTENANCE PROGRAM (cont.)

For the best forklift performance and operation, a maintenance program is required. Use the hour meter on

the instrument panel to keep maintenance properly scheduled (see SECTION TWO — “Servicing Schedule”).

For repairs on major components (engine, transmission, etc.), contact your nearest dealer for a Repair Manual.

Do not operate a forklift that is damaged or does not function properly. Only authorized personnel may make

repairs or adjustments to the lift truck. After repairs, the lift truck must be tested for safe operation before

returning to service.

3.) FORKLIFT KNOWLEDGE

Forklift trucks can cause serious injury if improperly used or maintained. Study all of the manuals provided for

your forklift model. Learn the locations and meanings of all safety decals. If any decals are illegible or missing, have them replaced immediately. Make sure all safety features provided by the original manufacturer are

in place and function properly. Do not operate a forklift with damaged, missing or unsafe components. Have

it repaired by authorized service personnel. Learn the functions of all controls, gauges, indicator lights, etc. on

the forklift. Know the speed/gear ranges, braking and steering capabilities, load ratings and clearances. When

referring to the location of forklift components, the terms “left”, “right”, “front”, and “rear” are related to the operator seated normally, facing forward in the operator’s seat. If you have any questions about the forklift, consult your supervisor. Failure to fully understand or obey safety warnings can result in serious injury or death!

4.) WORK SITE KNOWLEDGE

Before operating on a work site, learn the rules for movement of people, forklifts and all other traffic. Check

the size, weight, and condition of the loads you will be expected to handle. Verify that they are properly

secured and safe to transport. Learn where the loads are to be placed, planning your route for a safe

approach, watching for hazardous conditions. Will a signal man be required to help place the load? Remove

any debris which may cause tire damage or rupture. Plan your route around problem areas or have them corrected. Inform the supervisor of any unsafe conditions observed at the site. Examples of hazards: power

lines, cables, low clearance structures, garage doors, telephone pole guide lines, fencing, loose lumber, building materials, drop-offs, trenches, rough/soft spots, oil spills, deep mud, steep inclines, railroad tracks, curbs,

etc.. NEVER approach power lines, gas lines or other utilities with the forklift! Always verify that local,

state/provincial and federal regulations have been met. Report any accidents involving personnel, building

structures, and equipment to the supervisor immediately. Always remain alert — conditions are constantly

changing at the work site!

TECHNICAL SUPPORT

All data provided in this manual is subject to production changes, addition of new models, and improved product designs. If a question arises regarding your forklift, please consult your dealer or Manitou-NA, Inc. for the

latest information. When ordering service parts or requesting technical information, be prepared to quote the

applicable Model/Serial Numbers.

VIII

SAFETY MESSAGES

NOTE THE SAFETY ALERT SYMBOL (SHOWN BELOW). IT IDENTIFIES POTENTIAL

HAZARDS WHICH, IF NOT AVOIDED MAY RESULT IN INJURY OR DEATH!

the safety messages places throughout this manual; providing special instructions, telling you when to take precautions

and to identify potential hazards. The safety messages are highlighted and outlined in a box similar to those shown in the

examples below.

SAFETY ALERT SYMBOL

Also, observe

NOTE or NOTICE

Provides information, special instructions or references about the lift truck.

IMPORTANT

Precautions which must be taken to avoid damage to the lift truck.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. May also alert unsafe practices.

WARNING

Indicates a potentially hazardous situation which, if not avoided, may result in death or

serious injury!

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

CALIFORNIA PROPOSITION 65 WARNING

Diesel Engine Exhaust and some of its constituents are known to the State of California

to cause cancer, birth defects or other reproductive harm.

WARNING: Battery posts, terminals and related accesories and related accessories

contain lead and lead compounds. Wash hands after handling.

IX

The purpose of this chapter is to introduce you to the safety messages, decals, and nameplates found on

your forklift truck. The decals are identified by name, part number, location, and a brief description. (The

forklift model logos, and other misc. decals not shown, can be found in your forklift parts manual.) The

decals illustrated may not be exactly the same as those installed on your forklift; installation of the decals

varies depending on the forklift model, series, decal updates, etc.. The size and location of some decals

limit the amount of information that can be placed upon it. For this reason, additional detailed information

not found on the decals is provided through-out this manual.

Every decal placed on the lift truck is important; they are constant reminders of safety and instructions that

should never be taken for granted. Even experienced operators can be seriously injured or killed by ignoring, refusing to enforce, or forgetting to follow safe operating procedures! Do not assume you know all safety issues concerning the decals. Before operating the lift truck; learn the meaning(s) of the decals as

described in this manual. If any decal becomes illegible or missing, have it replaced immediately! Always

replace decals using the same decal part no., unless otherwise specified by the manufacturer. For replacement decals not found in your parts manual, contact your nearest dealer. If you have any questions, contact

your supervisor or nearest dealer for advice before operating your forklift!

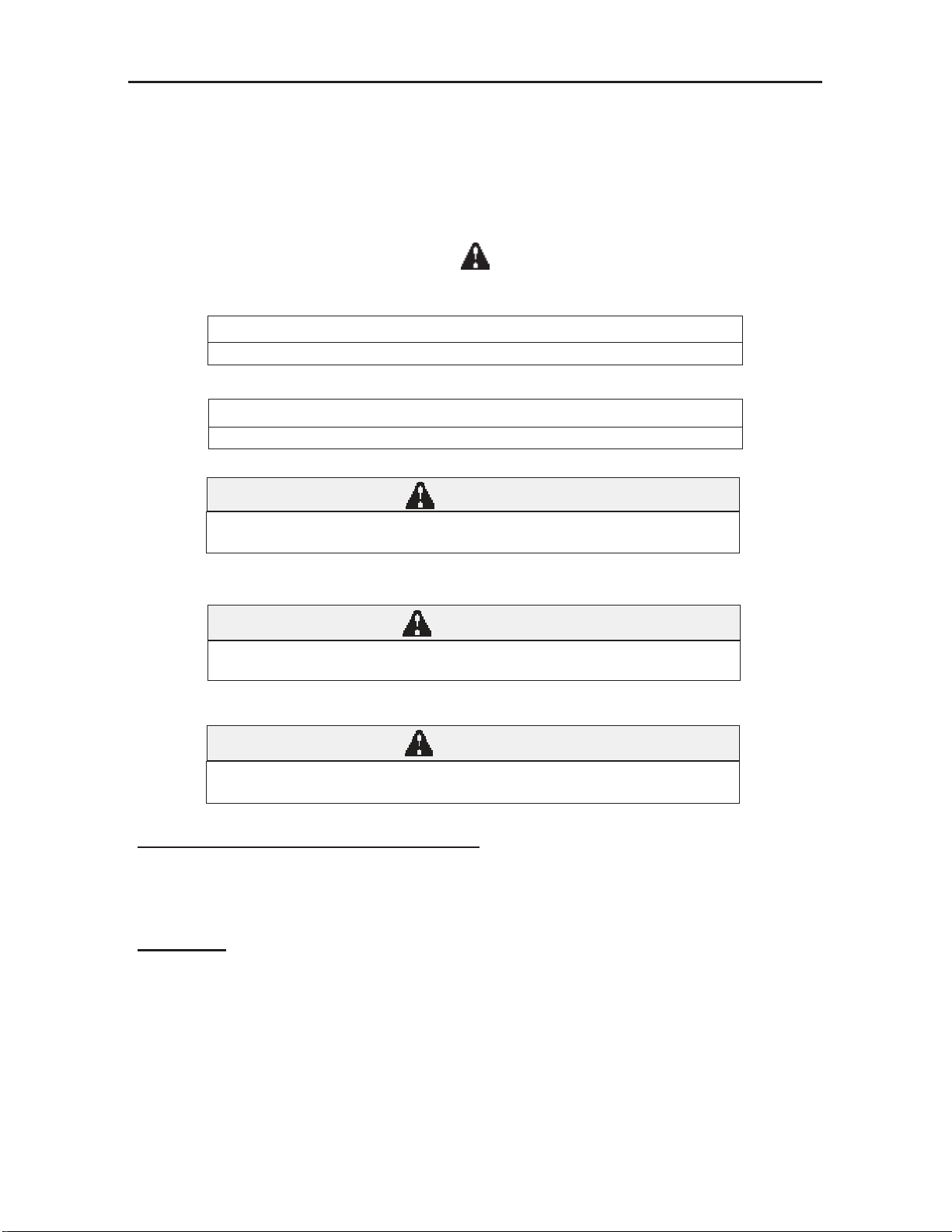

801011

Before Starting — 801011

(Boom equipped models). Location: on the brake fluid cover panel (to

the left and below the dash panel).

Safety Instructions — 420792

(Mast equipped models). Location: on or near the operator manual

storage case, and/or on the dash panel.

Instructions for the forklift operator; before operating the forklift.

Use of Seat Belt — 801012

(Boom equipped models). Location: to the right of the

operator, near the hydraulic control lever.

Instructs the operator to always wear the seat belt during

operations, and never jump from an over-turning forklift.

X

Emergency and Parking Brake — 801010

Location: near the park brake lever.

Identifies the Emergency/Parking Brake Lever.

Alarm Must Sound — 496162

Location: on the dash, in direct view of the operator.

The backup alarm must sound when the forklift is placed in reverse gear.

No Riders — 420732

Location: on the cab entrance(s), and on or near wheel fenders and engine

cover.

Informs: riders are not allowed on the forklift.

Clear of Raised Boom — 801006

(Boom equipped models). Location: on both sides

of the boom nose.

Keep away from unsupported boom.

Clear of Power Lines — 801007

(Boom equipped models). Location: on both sides

of the boom nose.

Keep away from power lines.

XI

Use of Frame Leveling — 801013

(Boom equipped models). Location: to the right of

the operator near the hydraulic control lever.

Frame leveling notice; load must be lowered.

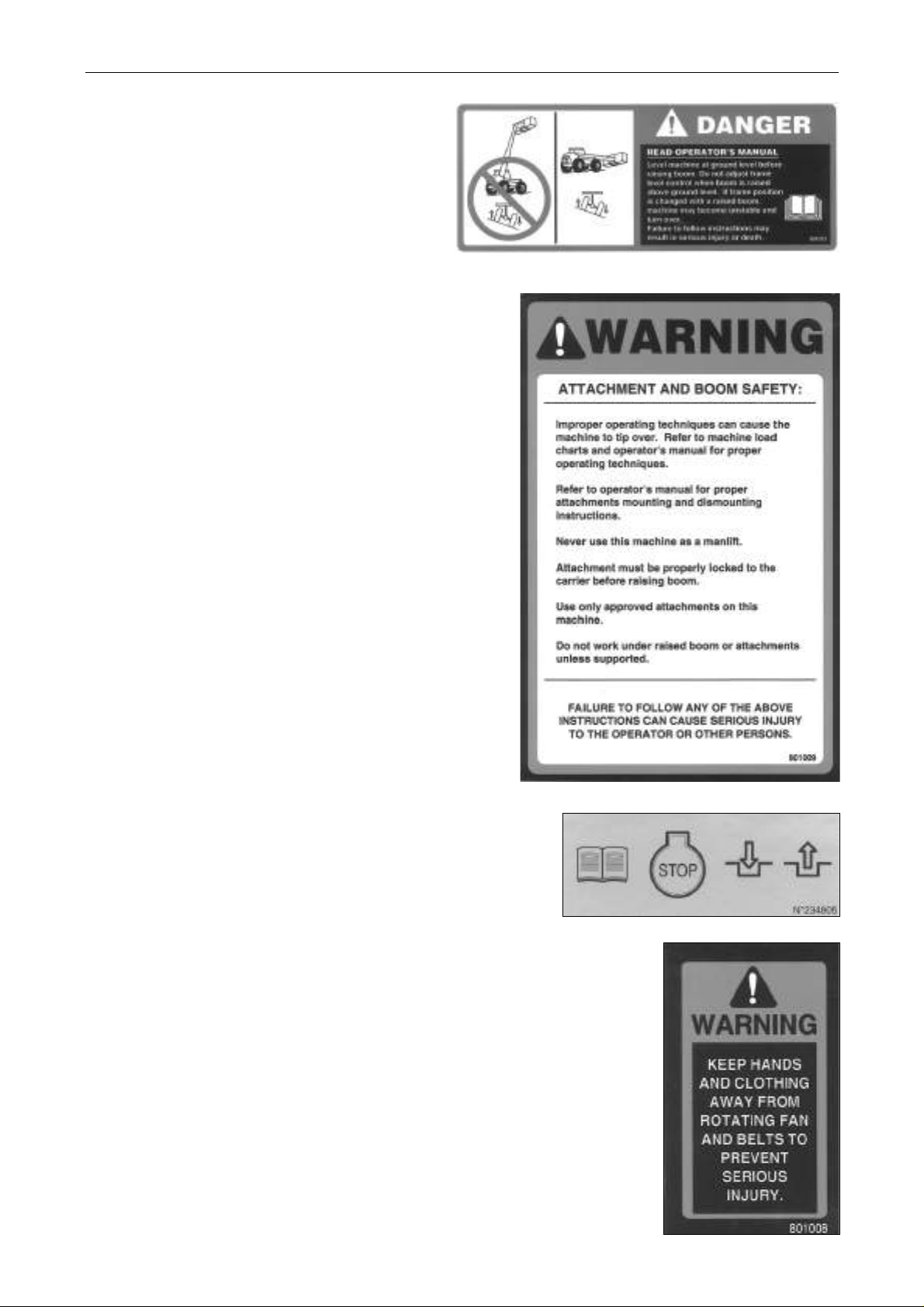

Attachment and Boom Safety — 801009

(Boom equipped models). Location: on both sides of the

boom nose.

Important reminders of attachment and boom safety.

Hydraulic Coupling — 234805

Location: near the quick-disconnect adapters.

Stop the engine and release hydraulic pressure before changing

attachments.

Rotating Fan and Belt(s) — 801008

Location: on the radiator near the fan, and on any fan belt/pulley cover(s).

Keep hands and clothing away from rotating fan and belts.

XII

Gear Shift Pattern — 33460

(4-speed transmission models). Location: near the gear shift lever.

Identifies the gear shift pattern of the forklift transmission.

Steering Mode — 184276

(4 wheel steer equipped models). Location: near the steering mode selection lever.

Identifies the steering mode selection.

Mineral Oil (Brake Reservoir) — 221322 or 234800 has

been replaced by 164091.

Location: near the brake fluid reservoir where applicable.

Refer to the Operator/Service Manual for the correct brake fluid

(mineral oil) to be used in the brake system.

XIII

Hydraulic Oil — 234798 or 76573

Location: on the hydraulic tank or filler cap.

Identifies the hydraulic reservoir (tank) or filler cap.

Hydraulic Oil — 61024

Location: on the hydraulic tank.

Identifies the hydraulic reservoir (tank).

Anti-Freeze — 234799

Location: on the radiator, near the radiator filler cap.

Indicates required minimum to maximum anti-freeze protection (-22

Diesel Fuel — 161101

Location: on the fuel tank, near the filler cap.

Identifies the fuel tank, and use of diesel fuel.

No Step — 496735

Location: varies, depending on the forklift model.

Instructs personnel not to use the designated area as a step.

0

F to -400F).

Do Not Tow — 494918

(Hydrostatic equipped models). Location: on the

dash, in view of the operator.

Towing the forklift will damage the transmission;

refer to the operator’s manual.

XIV

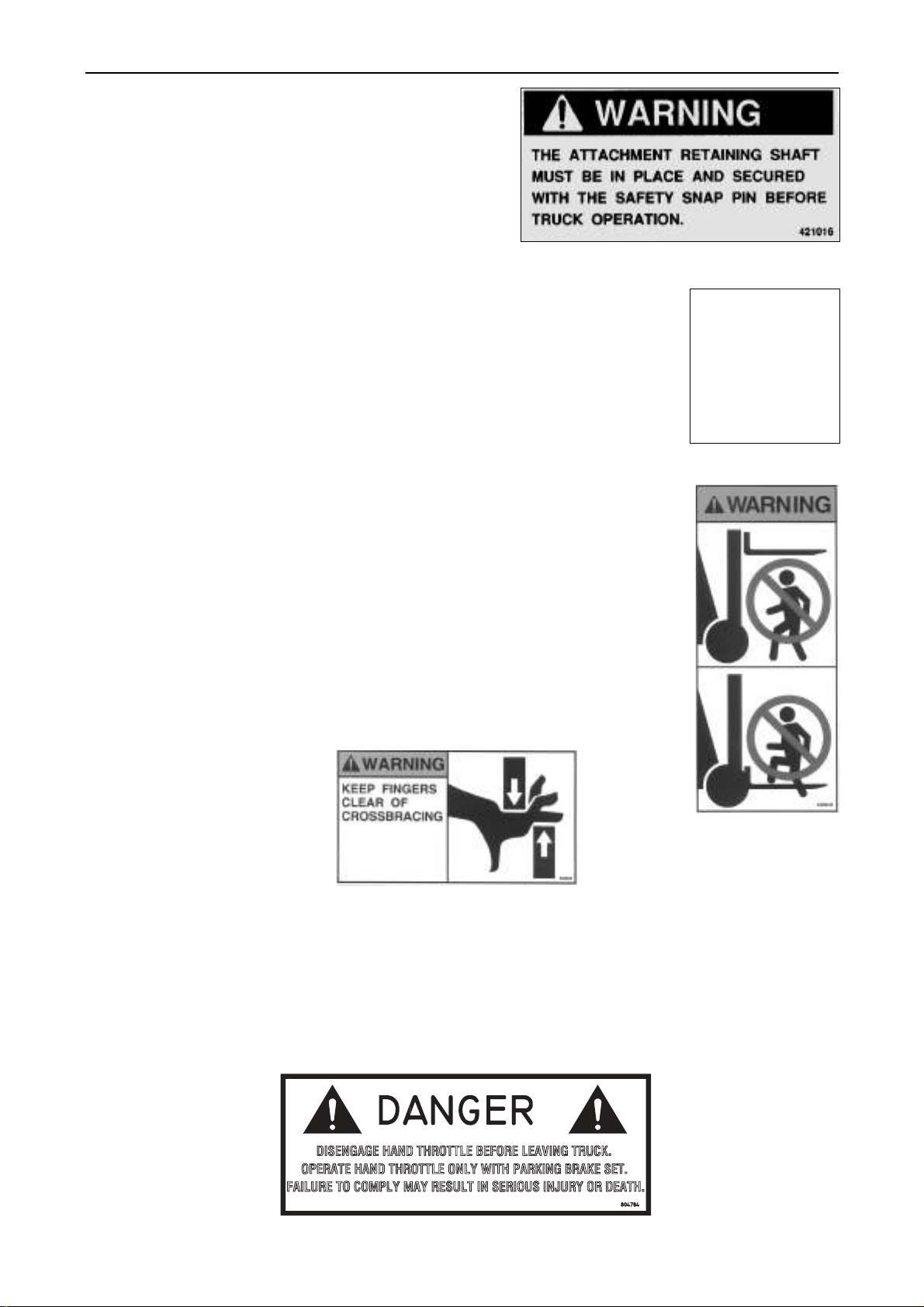

Attachment Warning — 421016

(Boom equipped models). Location: on the boom coupler,

near where the retaining shaft is installed.

Reminder to operator; install attachment retaining shaft and

safety pin before operations.

Hook Here — 24653

Location: at points provided on the forklift, where straps or chains may be attached to

secure the forklift to a trailer during transport.

Fork Safety — 426641

(Mast equipped models). Location: on the front and back side of the mast’s outer rails,

at eye level (4 required).

Instructs personnel not to travel beneath or upon the lift truck forks.

Pinch Point, Large, 2.5 x 4.5 in. — 426643

Pinch Point, Small, 1.5 x 2.75 in. — 426642

(Mast equipped models). Location: on the front and rear sides

of the mast cross bracing.

Keep fingers away from the mast

crossbracing.

HAND THROTTLE DANGER — 804784

(Boom equipped models, option). Location: Near the hand throttle mechanism.

Reminder to operator; set parking brake before operating hand throttle.

Disengage hand throttle before leaving the forklift.

XV

Acid in Battery — 801014

Location: in or near the battery

storage compartment.

Addresses battery hazards.

Jump Start Battery — 801015

Location: in or near the battery storage

compartment.

Jump start instructions.

Attachment Plate — 425995

Location: on the optional removeable forklift attachment.

Important manufacturer information about the attachment. Record this information for use

when contacting the maufacturer for parts and service.

Overhead Guard Data Plate — B6109

Location: attached to the overhead guard.

Overhead guard conformity.

496550

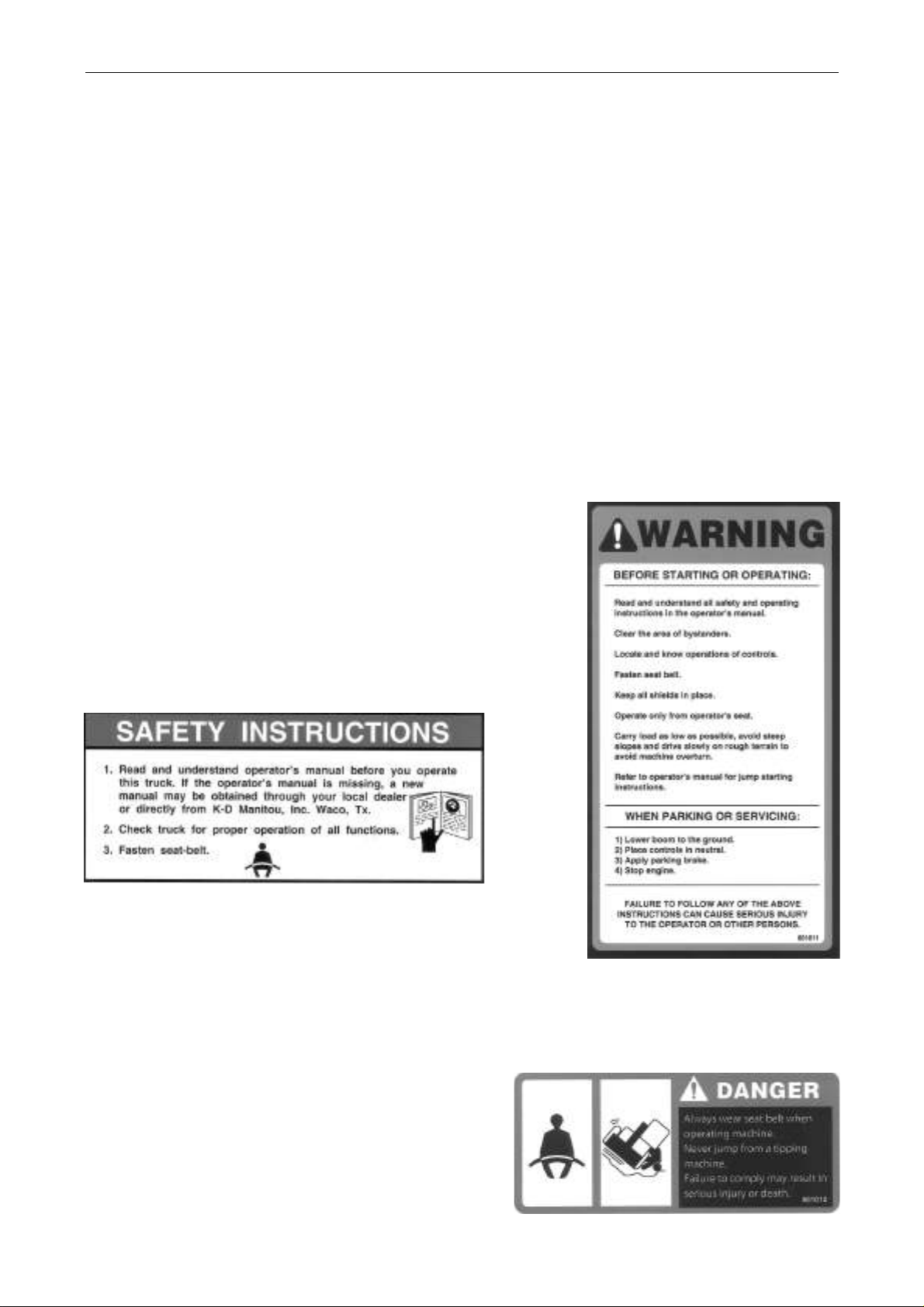

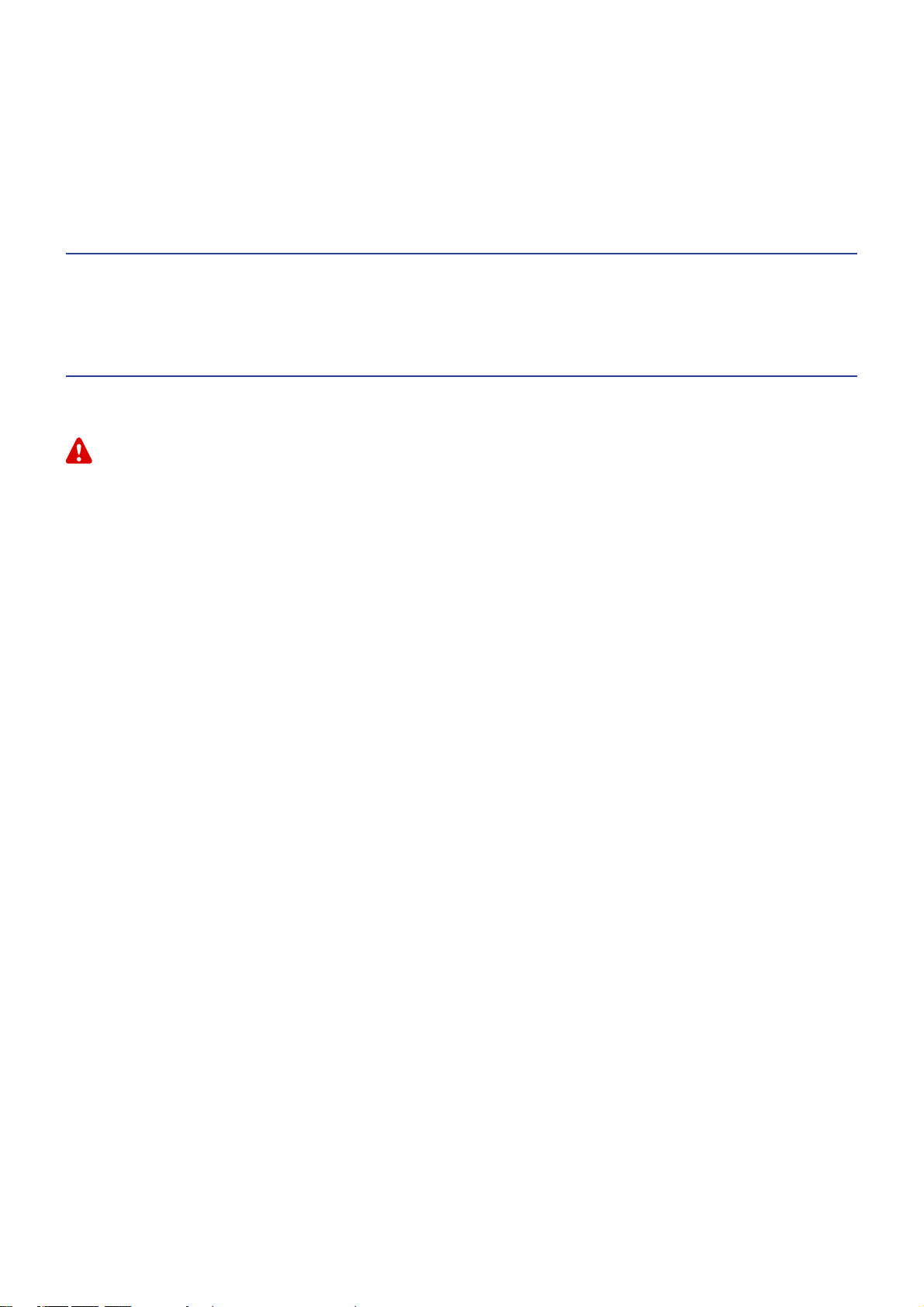

Forklift Data Plate — 496550

(Boom equipped models)

Forklift Data Plate — 283688

Location: within the operator’s compartment.

Important forklift truck identification. Record

this information for use when contacting the

manufacturer for parts and service.

MANITOU BF 44158 ANCENIS CEDEX FRANCE

MODELE

MODEL

Année de fabrication

Year of manufacture

Anno di fabbricazione

Año de fabricacion

Puissance ISO/TR14396

Power ISO/TR14396

Potenza ISO/TR14396

Potencia ISO/TR14396

Effort vertical max.

Vertical max. effort (on trailer hook)

Carico max. verticale (sul gancio di traino)

Esfuerzo vertical max. (sobre el gancho de remolque)

Pression des pneumatiques (Bar)

Tyre pressure (Bar)

Pressione per pneumatici (Bar)

Presion de los neumáticos (Bar)

Avant

Anteriore

Front

Adelante

283688

MODELLO

MODELO

kW

(sur accrochage remorque)

daN

Arrière

Posteriore

Rear

Trasero

SERIE

SERIES

N° de série

Serial Nr

Número de serie

Masse à vide

Unladen mass

Numéro d’homologation

Homologation number

Numero d’omologazione

Contraseña homologacion

Capacité maxi nominale

Nominal maximum capacity

Capacità maxi nominale

Capacidad máximo nominal

Effort de traction

Tractive effort

Forza di traino

Esfuerzo de traccion

N°283688

SERIE

SERIE

Numero di serie

Massa a vuoto

Masa en vacio

daN

kg

kg

XVI

1 — OPERATING

AND SAFETY

INSTRUCTIONS

1-1

1-2

TABLE OF CONTENTS

INSTRUCTIONS TO THE COMPANY MANAGER

THE SITE

THE OPERATOR

THE LIFT TRUCK

A — THE LIFT TRUCK’S SUITABILITY FOR THE JOB

B — ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS

C — MODIFICATION OF THE LIFT TRUCK

D — FRENCH ROAD TRAFFIC RULES

THE INSTRUCTIONS

THE MAINTENANCE

(or see current legislation in other countries)

INSTRUCTIONS FOR THE OPERATOR

PREAMBULE

GENERAL INSTRUCTIONS

A — OPERATOR’S MANUAL

B — AUTHORIZATION FOR USE IN FRANCE

C — MAINTENANCE

D — MODIFICATION OF THE LIFT TRUCK

E — LIFTING PEOPLE

OPERATING INSTRUCTIONS UNLADEN AND LADEN

A — BEFORE STARTING THE LIFT TRUCK

B — DRIVER’S OPERATING INSTRUCTIONS

C — ENVIRONMENT

D — VISIBILITY

E — STARTING THE LIFT TRUCK

F — DRIVING THE LIFT TRUCK

G — STOPPING THE LIFT TRUCK

H — DRIVING THE LIFT TRUCK ON THE PUBLIC HIGHWAY

INSTRUCTIONS FOR HANDLING A LOAD

A — CHOICE OF ATTACHMENTS

B — MASS OF LOAD AND CENTRE OF GRAVITY

C — LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE

D — TRANSVERSE ATTITUDE OF THE LIFT TRUCK

E — TAKING UP A LOAD ON THE GROUND

F — TAKING UP AND LAYING A HIGH LOAD ON TYRES

G — TAKING UP AND LAYING A HIGH LOAD ON STABILIZERS

H — TAKING UP AND LAYING DOWN A SUSPENDED LOAD

I — TRAVELLING WITH A SUSPENDED LOAD

PLATFORM OPERATING INSTRUCTIONS

A — AUTHORISATION FOR USE

B — SUITABILITY OF THE PLATFORM FOR THE JOB

C — PRECAUTIONS WHEN USING THE PLATFORM

D — USING THE PLATFORM

E — ENVIRONMENT

F — MAINTENANCE

INSTRUCTIONS FOR USING THE RADIO-CONTROL

(or see current legislation in other countries)

(or see current legislation in other countries)

1-4

1 — 4

1 — 4

1 — 4

1 — 4

1 — 4

1 — 5

1 — 5

1 — 5

1 — 5

1-6

1 — 6

1 — 6

1 — 6

1 — 6

1 — 6

1 — 6

1 — 7

1 — 8

1 — 8

1 — 8

1 — 9

1 — 9

1 — 10

1 — 10

1 — 11

1 — 12

1 — 14

1 — 14

1 — 14

1 — 14

1 — 15

1 — 15

1 — 16

1 — 18

1 — 20

1 — 20

1 — 21

1 — 21

1 — 21

1 — 21

1 — 21

1 — 21

1 — 22

1 — 23

MAINTENANCE INSTRUCTIONS OF THE LIFT TRUCK

GENERAL INSTRUCTIONS

MAINTENANCE

LUBRICANT AND FUEL LEVELS

HYDRAULIC

ELECTRICITY

WELDING

WASHING THE LIFT TRUCK

IF THE LIFT TRUCK IS NOT TO BE USED FOR A LONG TIME

INTRODUCTION

PREPARING THE LIFT TRUCK

PROTECTING THE I.C. ENGINE

PROTECTING THE LIFT TRUCK

BRINGING THE LIFT TRUCK BACK INTO SERVICE

1-24

1 — 24

1 — 24

1 — 24

1 — 24

1 — 24

1 — 25

1 — 25

1-26

1 — 26

1 — 26

1 — 26

1 — 26

1 — 27

INSTRUCTIONS TO THE COMPANY MANAGER

THE SITE

— Proper management of lift truck’s area of travel will reduce the risk of accidents:

. ground not unnecessarily uneven or obstructed,

. no excessive slopes,

. pedestrian traffic controlled, etc.

THE OPERATOR

— Only qualified, authorized personnel can use the lift truck. This authorization is given in writing by the appropriate person in the

establishment with respect to the use of lift trucks and must be carried permanently by the operator.

On the basis of experience, there are a number of possible situations in which operating the lift truck is contra-indicated. Such foreseeable abnormal

uses, the main ones being listed below, are strictly forbidden.

— The foreseeable abnormal behaviour resulting from ordinary neglect, but does not result from any wish to put the machinery to any improper use.

— The reflex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the lift truck.

— Behaviour resulting from application of the «principle of least action» when performing a task.

— For certain machines, the foreseeable behaviour of such persons as: apprentices, teenagers, handicapped persons, trainees tempted to drive a

lift truck, operator tempted to operate a truck to win a bet, in competition or for their own personal experience.

The person in charge of the equipment must take these criteria into account when assessing whether or not a person will makea suitable driver.

THE LIFT TRUCK

A — THE TRUCK’S SUITABILITY FOR THE JOB

— MANITOU has ensured that this lift truck is suitable for use under the standard operating conditions defined in this operator’s

manual, in accordance to ASME B56.6 — 2002

— Before commissioning, the company manager must make sure that the lift truck is appropriate for the work to be done, and

perform certain tests (in accordance with current legislation).

B — ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS

— In addition to series equipment mounted on your lift truck, many options are available, such as: road lighting, stop lights, flashing

light, reverse lights, reverse buzzer alarm, front light, rear light, light at the jib head, etc… (as model of lift truck).

— The operator must take into account the operating conditions to define the lift truck’s signalling and lighting equipment.

Contact your dealer.

— Take into account climatic and atmospheric conditions of the site of utilisation.

. Protection against frost (see: 3 — MAINTENANCE: LUBRICANTS AND FUEL).

. Adaptation of lubricants (ask your dealer for information).

. I.C. engine filtration (see: 3 — MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

For operation under average climatic conditions, i.e.: between — 15 °C and + 35 °C, correct levels of lubricants in all the circuits are checked in production.

For operation under more severe climatic conditions, before starting up, it is necessary to drain all the circuits, then ensure correct levels of lubricants

using lubricants properly suited to the relevant ambient temperatures. It is the same for the cooling liquid.

— A lift truck operating in an area without fire extinguishing equipment must be equipped with an individual extinguisher. There are

solutions, consult your dealer.

Your lift truck is designed for outdoor use under normal atmospheric conditions and indoor use in suitably aerated and ventilated premises. It is prohibited

to use the lift truck in areas where there is a risk of fire or which are potentially explosive (e.g. Refineries, fuel or gas depots, stores of inflammable

products…). For use in these areas, specific equipment is available (ask your dealer for information).

— Our trucks comply with Directive 2004/108/EC concerning electromagnetic compatibility (EMC), and with the corresponding

harmonized norm EN 12895. Their proper operation is no longer guaranteed if they are used within areas in which the

electromagnetic fields exceed the limit specified by that norm (10 V/m).

— Directive 2002/44/EC requires company managers to not expose their employees to excessive vibration doses. There is no

recognized code of measurement for comparing the machines of different manufacturers. The actual doses received can therefore

be measured only under actual operating conditions at the user’s premises.

— The following are some tips for minimizing these vibration doses:

• Select the most suitable lift truck and attachment for the intended use.

• Adapt the seat adjustment to the operator’s weight (according to lift truck model) and maintain it in good condition, as

well as the cab suspension. Inflate the tires in accordance with recommendations.

• Ensure that the operators adapt their operating speed to suit the conditions on site.

• As far as possible, arrange the site in such a way as to provide a flat running surface and remove obstacles and harmful

potholes.

1-4

C — MODIFICATION OF THE LIFT TRUCK

— For your safety and that of others, you must not change the structure and settings of the various components used in your lift truck

(hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight, unapproved

attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

D — FRENCH ROAD TRAFFIC RULES

(or see current legislation in other countries)

— Only one certificate of conformity is issued. It must be kept in a safe place.

THE INSTRUCTIONS

— The operator’s manual must always be in good condition and kept in the place provided on the lift truck and in the language used

by the operator.

— The operator’s manual and any plates or stickers which are no longer legible or are damaged, must be replaced immediately.

THE MAINTENANCE

— Maintenance or repairs other than those detailed in part: 3 — MAINTENANCE must be carried out by qualified personnel (consult

your dealer) and under the necessary safety conditions to maintain the health of the operator and any third party.

Your lift truck must be inspected periodically to ensure that it remains in compliance. The frequency of this inspection is defined by current legislation in

the country in which the lift truck is used.

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

WHENEVER YOU SEE THIS SYMBOL IT MEANS:

WARNING ! BE CAREFUL ! YOUR SAFETY OR THE SAFETY OF THE LIFT TRUCK IS AT RISK.

The risk of accident while using, servicing or repairing your lift truck can be restricted if you follow the safety instructions and safety measures detailed

in these instruction.

— Only the operations and manœuvres described in these operator’s manual must be performed. The manufacturer cannot predict

all possible risky situations. Consequently, the safety instructions given in the operator’s manual and on the lift truck itself are

not exhaustive.

— At any time, as an operator, you must envisage, within reason, the possible risk to yourself, to others or to the lift truck itself

when you use it.

Failure to respect the safety and operating instructions, or the instructions for repairing or servicing your lift truck may lead to serious, even fatal

accident.

GENERAL INSTRUCTIONS

A — OPERATOR’S MANUAL

— Read the operator’s manual carefully.

— The operator’s manual must always be in good condition and in the place provided for it on the lift truck.

— You must report any plates and stickers which are no longer legible or which are damaged.

B — AUTHORISATION FOR USE IN FRANCE

(or see current legislation in other countries)

— Only qualified, authorized personnel can use the lift truck. This authorization is given in writing by the appropriate person in the

establishment with respect to the use of lift trucks and must be carried permanently by the operator.

— The operator is not competent to authorise the driving of the lift truck by another person.

C — MAINTENANCE

— The operator must immediately advise his superior if his lift truck is not in good working order or does not comply with the safety

notice.

— The operator is prohibited from carrying out any repairs or adjustments himself, unless he has been trained for this purpose. He must

keep the lift truck properly cleaned if this is among his responsibilities.

— The operator must carry out daily maintenance (see: 3 — MAINTENANCE: A — DAILY OR EVERY 10 HOURS SERVICE).

— The operator must ensure tyres are adapted to the nature of the ground (see area of the contact surface of the tyres in the

chapter: 2 — DESCRIPTION: FRONT AND REAR TYRES). There are optional solutions, consult your dealer.

. SAND tyres.

. LAND tyres.

. Snow chains.

Do not use the lift truck if the tyres are incorrectly inflated, damaged or excessively worn, because this could put your own safety or that of others at

risk, or cause damage to the lift truck itself. The fitting of foam inflated tyres is prohibited and is not guaranteed by the manufacturer, excepting prior

authorisation.

D — MODIFICATION OF THE LIFT TRUCK

— For your safety and that of others, you must not change the structure and settings of the various components used in your lift truck

(hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight, unapproved

attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

1-6

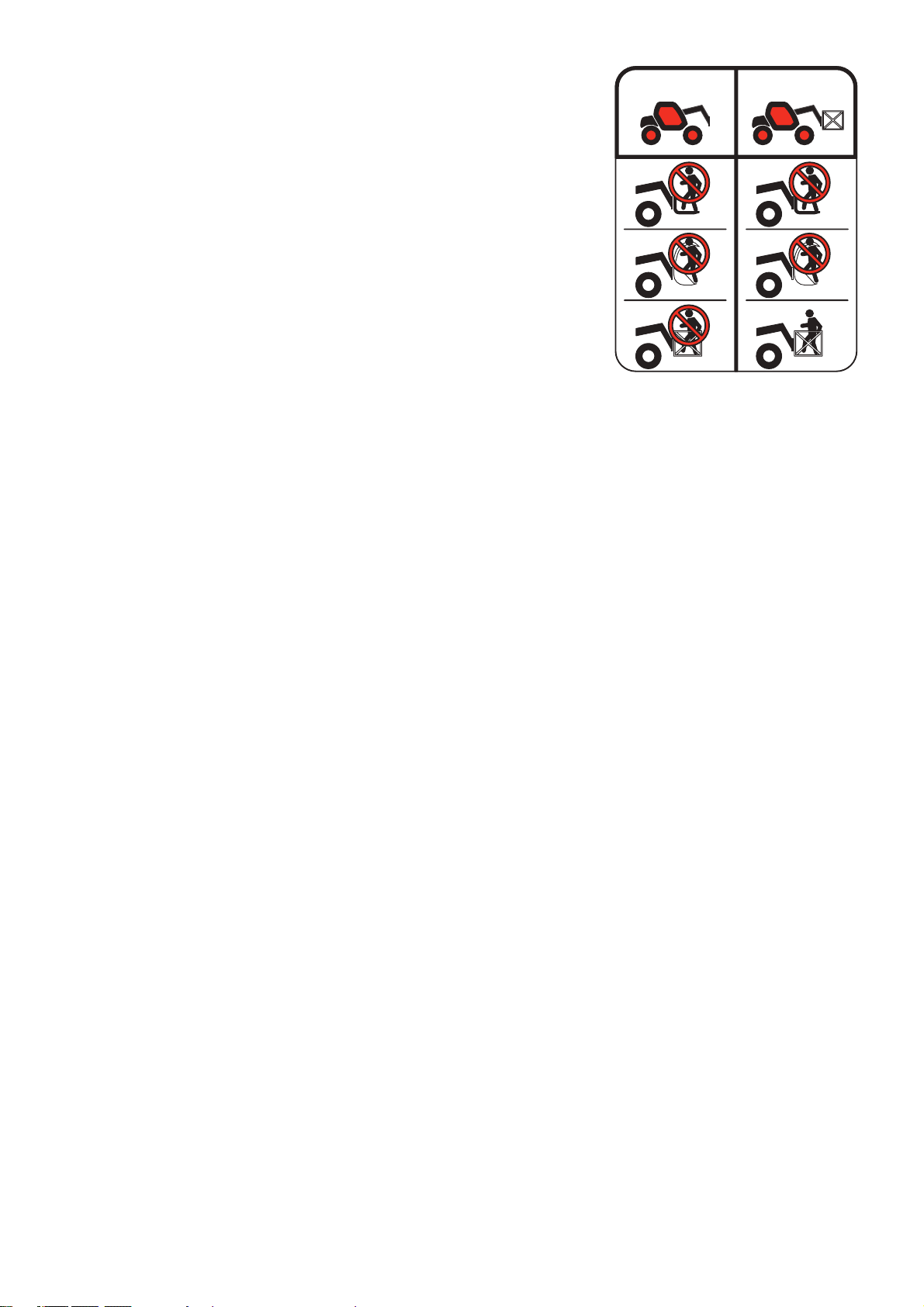

E — LIFTING PEOPLE

— The use of working equipment and load lifting attachments to lift people is:

• either forbidden

• or authorized exceptionally and under certain conditions (see current regulations

in the country in which the lift truck is used).

— The pictogram posted at the operator station reminds you that:

• Left-hand column

— It is forbidden to lift people, with any kind of attachment, using a non PLATFORM-

fitted lift truck.

• Right-hand column

— With a PLATFORM-fitted lift truck, people can only be lifted using platforms

designed by MANITOU for the purpose.

— MANITOU sells equipment specifically designed for lifting people (OPTION PLATFORM

lift truck, contact your dealer).

Loading…

manual de partes despiece en español

- Addeddate

- 2023-03-24 20:46:02

- Identifier

- manitou-mlt-735-mlt-741-mlt-742-lsu-manual-de-partes-998-paginas

- Identifier-ark

- ark:/13960/s2khgrg2gfm

- Ocr

- tesseract 5.3.0-3-g9920

- Ocr_detected_lang

- an

- Ocr_detected_lang_conf

- 1.0000

- Ocr_detected_script

- Latin

- Ocr_detected_script_conf

- 0.9794

- Ocr_module_version

- 0.0.20

- Ocr_parameters

- -l spa

- Page_number_confidence

- 14.34

- Ppi

- 300

comment

Reviews

There are no reviews yet. Be the first one to

write a review.

211

Views

DOWNLOAD OPTIONS

Temporarily Unavailable

DAISY

For users with print-disabilities

Temporarily Unavailable

EPUB

Uploaded by

Manuales Maquinaria

on

Sale!

Original price was: $ 50,00.Current price is: $ 40,00.

Manitou MLT 735 120 LSU S6-E3 Operator Manual

Format: PDF

Language: EN

Size: 6.58 MB

Pages: 178

Speed Download Link

Category: PDF

-

Description

Description

Manitou MLT 735 120 LSU S6-E3 Operator Manual

What does this catalog contain?

Manitou MLT 735 120 LSU S6-E3 Operator Manual contains high quality images, diagrams, instructions to help you to operate, maintenance, diagnostic, and repair your machine. This document is printable, without restrictions, contains searchable text and bookmarks for easy navigation.

Manitou MLT735 120 LSU S6-E3 Operator Manual includes:

- Numbered table of contents easy to use so that you can find the information you need fast.

- Detailed sub-steps expand on repair procedure information.

- Numbered instructions guide you through every repair procedure step by step.

- Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

- Notes, cautions and warnings throughout each chapter pinpoint critical information.

- Bold figure number help you quickly match illustrations with instructions.

- Detailed illustrations, drawings and photos guide you through every procedure.

- Enlarged inset helps you identify and examine parts in detail.

What will you get when you get this service catalog?

- After payment has been received, a few minutes later.

- Lifetime PDF and Access To Download (By Request).

- Compatible With Windows, Mac, IOS, Android and Other Systems.

- Searchable Text and Built-in Index For Instant Information Search Bookmarks.

- Printable – Pages Or Entire Manual.

- Zoomable – Detailed Exploded Diagrams, Picture.

TABLE OF CONTENT OF THE Manitou MLT 735-120 LSU S6-E3 Manual

0 – ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS

1 – OPERATING & SAFETY INSTRUCTION

2 – DESCRIPTION

3 – MAINTENANCE

4 – ATTACHMENT ENGAGEMENT

5 – ELECTRICAL & HYDRAULIC SCHEMATIC

MANITOU

Manitou MLT735 Operators Manual

Manitou MLT735 Operators Manual

Manitou MLT735 Operators Manual.pdf

Adobe Acrobat Document

3.3 MB

Manitou MT1440PE3 MT1840PE3 Lift Truck Operator’s Manual

Manitou MT1440PE3 MT1840PE3 Lift Truck Operator’s Manual

Manitou MT1440PE3 MT1840PE3 Lift Truck O

Adobe Acrobat Document

4.8 MB

2012 Manitou Service Manual

2012 Manitou Service Manual

2012 Manitou Service Manual.pdf

Adobe Acrobat Document

2.1 MB

Some MANITOU Forklift Truck Manuals PDF above the page — MLT735, MT1440, MT1840.

1958 — Created the first masted forklift terrain and launches the brand MANITOU.

1970 — Start of international expansion of the company.

1972 — partnership agreement with TOYOTA for sale TOYOTA industrial trucks in France.

1981 — Launch of the first models of telehandlers.

1984 — Launch of the company’s shares MANITOU on the securities market in Paris.

1991 — Launch of sales of telehandlers in the agricultural market.

1993 — Takeover of LOC MANUTENTION and expansion of activities to the production of warehouse equipment.

1995 — Start of production of lifting platforms and trailer trucks.

1995 — Creation of a joint venture with TOYOTA for the production of industrial loaders for sale in Europe.

1997 — Partnership with CASE NEW HOLLAND.

2003 — Creation of production sites in the US and in Italy.

2004 — MANITOU marks the release of the 200,000th truck terrain and changing the logo. The partnership

agreement for the production and sales with the company GEHL (United States).

2005 — Updating the ISO 9001 certificate, issued by BVQI. Creating a branch in Australia.

2007 — Manitou opens an international logistics center for the shipment of spare parts area of 33 500m².

-

Вернуться к

Ручные инструкции пользователя

Руководство по эксплуатации телескопического погрузчика Manitou MLT 634 731 735 741 1035

- 0 раз купили

- 0 оценка

- 5 осталось

-

0 отзывов

-

Почта России

1582 ₽

-

Курьерская доставка EMS

2106 ₽

Характеристики

Tytuł

Instrukcja obsługi Ładowarka teleskopowa Manitou MLT 634 731 735 741 1035

Описание

Przedmiotem mojej dzisiejszej aukcji jest instrukcja obsługi do ładowarek teleskopowych:

MANITOU

MLT 634 Turbo LSU seria E-E3

MLT 634 — 120 LSU seria E-E3

MLT 634 — 120 LSU POWERSHIFT seria E-E3

MLT 731 Turbo seria E-E3

MLT 735 Turbo LSU seria 5-E3

MLT 735 — 120 LSU seria 5-E3

MLT 735 — 120 LSU POWERSHIFT seria 5-E3

MLT 741 — 120 LSU seria 5-E3

MLT 741 — 120 LSU POWERSHIFT seria 5-E3

MLT 1035 L Turbo LSU seria 5-E3

- Instrukcja jest w języku polskim

- Ilość stron 188

Zawarte w instrukcji informacje pomogą Ci prawidłowo i bezpiecznie kierować maszyną i wykonywać zamierzone prace przy możliwie najmniejszym wysiłku.

Przy przestrzeganiu zasad eksploatacji, obsługi technicznej, oraz zasad bezpieczeństwa, ciągnik będzie dla Ciebie niezawodnym i wieloletnim partnerem.

-

Гарантии

Мы работаем по договору оферты и предоставляем все необходимые

документы. -

Лёгкий возврат

Если товар не подошёл или не соответсвует описанию, мы поможем

вернуть его. -

Безопасная оплата

Банковской картой, электронными деньгами, наличными в офисе

или на

расчётный счёт.

Рейтинг

товара 0 / 5

0 отзывов