en

Operator’s Manual

bg

Инструкции за експлоатация

cs

Návod k obsluze

et

Kasutusjuhend

hr

Priruènik za operatora

hu

Kezelési útmutató

lt

Naudojimo instrukcija

lv

Operatora rokasgrāmata

pl

Instrukcja obs³ugi

ro

Manual de utilizare

ru

Руководство по эксплуатации

sl

Priroènik za uporabo

Model 120000

Vanguardt

RUN

Model 200000

Vanguardt

Briggs & Stratton is a registered trademark

of Briggs & Stratton Corporation

English

en

Български LietuviųMagyar Slovenšèina

bg cs hr slet hu

Èeština

eesti keel Hrvatski Latviešu Polski Русский

E 2008 Briggs & Stratton Corporation,

Milwaukee, WI, USA. All rights reserved.

lt lv pl ro ru

Form No. 277552EST A

Românã

1

I

RUN

D

E

M

J

K

H

C

F

C

B

H

A

L

H

G

N

2

A

C

4

5

AB

A

B

F

G

3

C

A

B

C

D

B

E

2

A

BRIGGSandSTRATTON.COM

D

6

RUN

A

7

B

A

A

8

10

A

B

A

9

D

B

C

E

F

D

D

E

11

A

A

D

B

C

F

G

12

E

D

A

B

C

A

B

13

14

C

B

RUN

B

A

3

General Information

For replacement parts or technical assistance, record below the engine model, type, and

code numbers along with the date of purchase. These numbers are located on your

engine (see the Features and Controls page).

WARNING

The engine exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects, or other

reproductive harm.

Date of purchase:

MM/DD/YYYY

Engine model:

Model: Code:Type:

Engine Power Rating Information

The gross power rating for individual gas engine models is labeled in accordance with

SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been obtained and corrected in

accordance with SAE J1995 (Revision 2002-05). Torque values are derived at 3060

RPM; horsepower values are derived at 3600 RPM. Actual gross engine power will be

lower and is affected by, among other things, ambient operating conditions and

engine-to-engine variability. Given both the wide array of products on which engines are

placed and the variety of environmental issues applicable to operating the equipment,

the gas engine will not develop the rated gross power when used in a given piece of

power equipment (actual “on-site” or net power). This difference is due to a variety of

factors including, but not limited to, accessories (air cleaner, exhaust, charging, cooling,

carburetor, fuel pump, etc.), application limitations, ambient operating conditions

(temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing

and capacity limitations, Briggs & Stratton may substitute an engine of higher rated

power for this Series engine.

Operator Safety

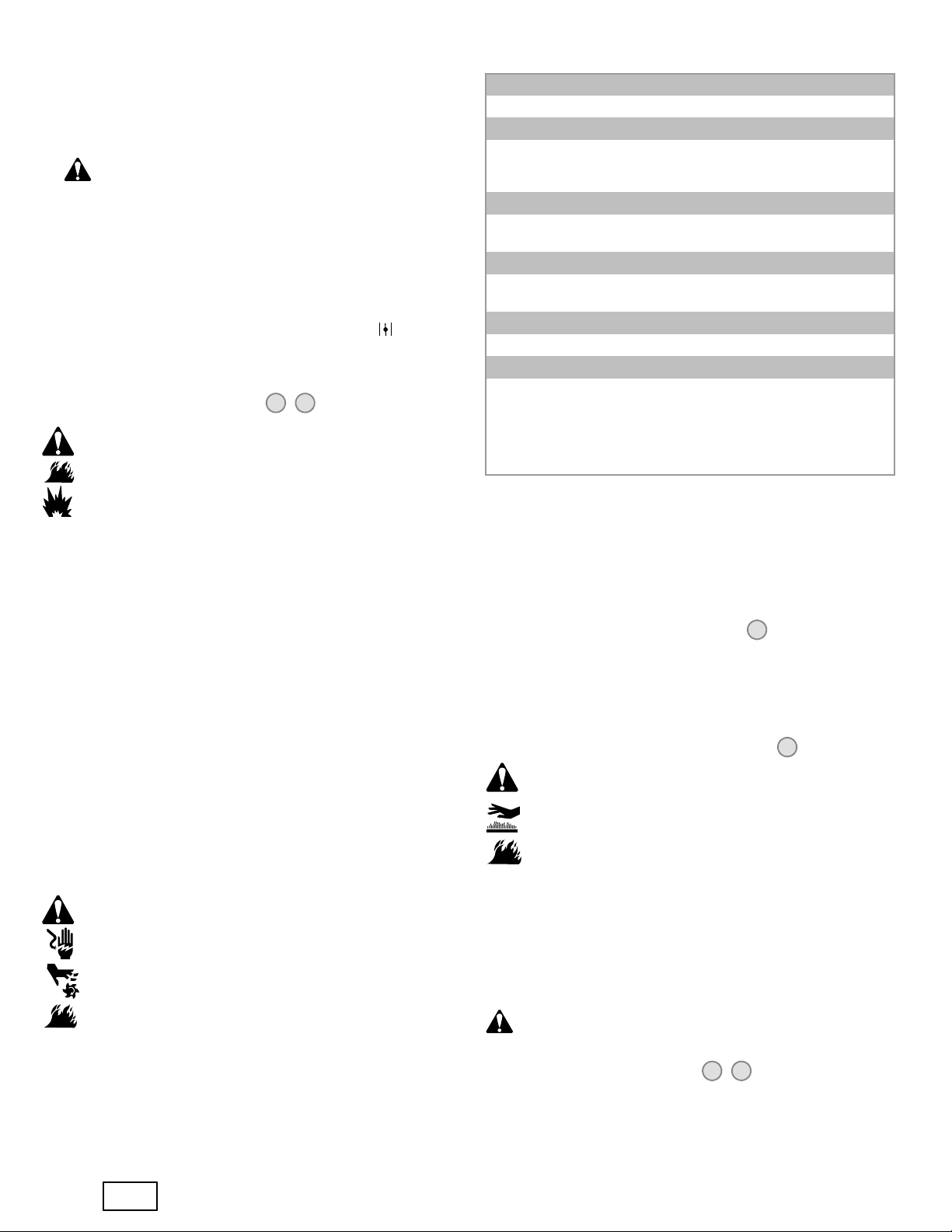

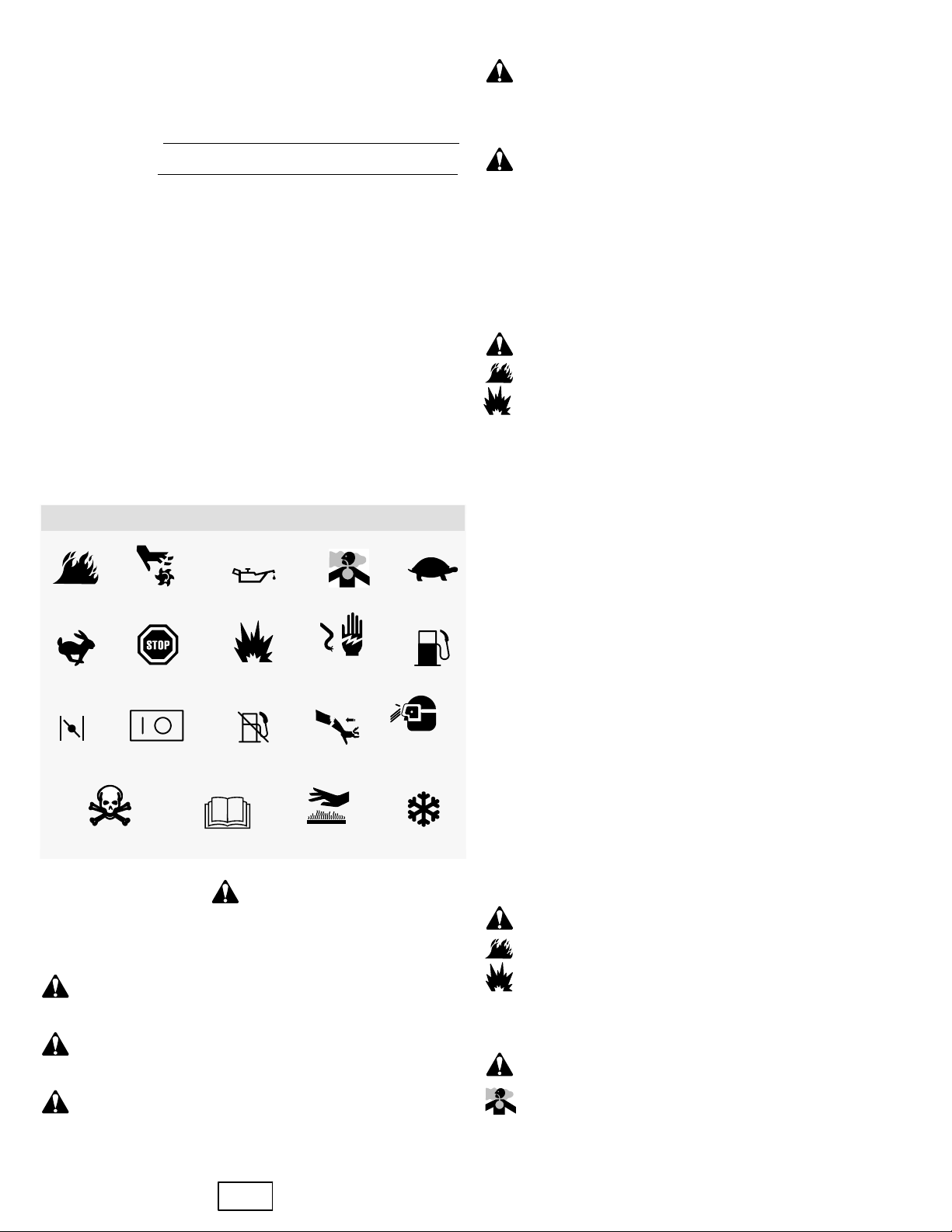

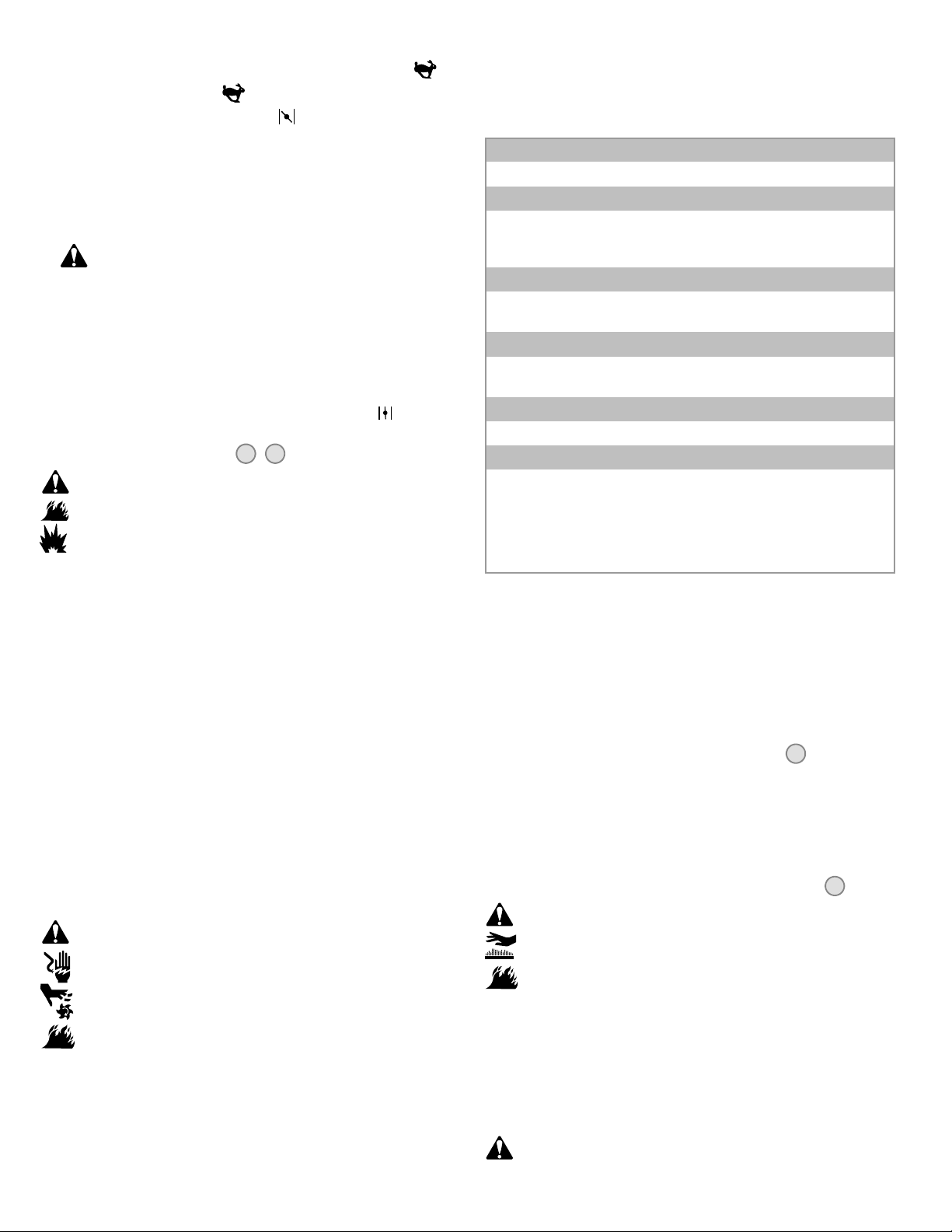

SAFETY AND CONTROL SYMBOLS

Fire

Fast

Choke

Hazardous

Chemical

Moving Parts

Stop

On Off

Read Manual

Oil

Explosion

Fuel Shutoff

Hot Surface

Toxic Fumes

Shock

Kickback

Frostbite

Slow

Fuel

Wear Eye

Protection

WARNING

Briggs & Stratton does not approve or authorize the use of these

engines on 3-wheel All Terrain Vehicles (ATVs), motor bikes,

fun/recreational go-karts, aircraft products, or vehicles intended for

use in competitive events. Use of these engines in such applications

could result in property damage, serious injury (including paralysis),

or even death.

CAUTION: This engine was shipped from Briggs & Stratton without oil. Before you start

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill f uel tank. Fill tank to approximately 1.5 inches (38 mm) below top of

neck to allow for fuel expansion.

• Keep gasoline away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary

• If fuel spills, wait until it evaporates before starting engine.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place

and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle (if

equipped) to FAST position and crank until engine starts.

When Operating Equipment

• Do not tip engine or equipment at angle which causes gasoline to spill.

• Do not choke the carburetor to stop engine.

• Never start or run the engine with the air cleaner assembly (if equipped) or the air

filter (if equipped) removed.

When Changing Oil

• If you drain the oil from the top oil fill tube, the fuel tank must be empty or fuel can

leak out and result in a fire or explosion.

When Transporting Equipment

• Transport with fuel tank EMPTY or with fuel shut-off valve OFF.

When Storing Gasoline Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

light or other ignition source because they can ignite gasoline vapors.

The safety alert symbol

result in personal injury. A signal word (DANGER, WARNING, or CAUTION) is used with the

alert symbol to indicate the likelihood and the potential severity of injury. In addition, a hazard

symbol may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazard which, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if not avoided, might result in minor or

moderate injury.

CAUTION, when used without the alert symbol, indicates a situation that

could result in damage to the product.

is used to identify safety information about hazards that can

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do not start engine.

• Do not use pressurized starting fluids because vapors are flammable.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if doors or windows are open.

4 BRIGGSandSTRATTON.COM

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward

engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

• Remove all external equipment/engine loads before starting engine.

• Direct-coupled equipment components such as, but not limited to, blades, impellers,

pulleys, sprockets, etc., must be securely attached.

WARNING

Rotating parts can contact or entangle hands, feet, hair, clothing, or

accessories.

Traumatic amputation or severe l aceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling drawstrings or items that could become

caught.

WARNING

Running engines produce heat. Engine parts, especially muffler, become

extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• Install and maintain in working order a spark arrester before using equipment on

forest-covered, grass-covered, brush-covered unimproved land. The state of

California requires this (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal land.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation,

or laceration.

Fire hazard

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Disconnect battery at negative terminal (only engines with electric start.)

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be the same and installed in the same position as the

original parts.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

en

5

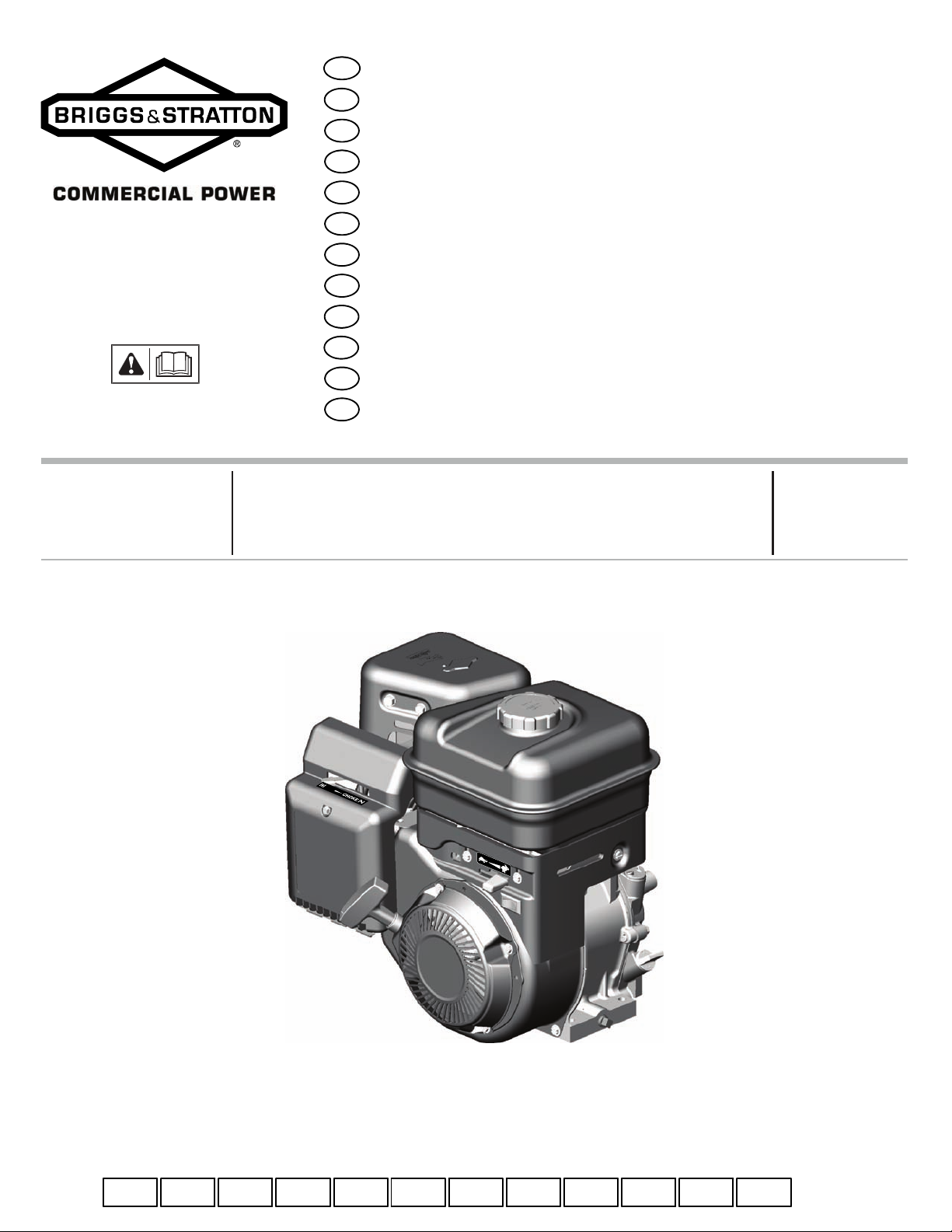

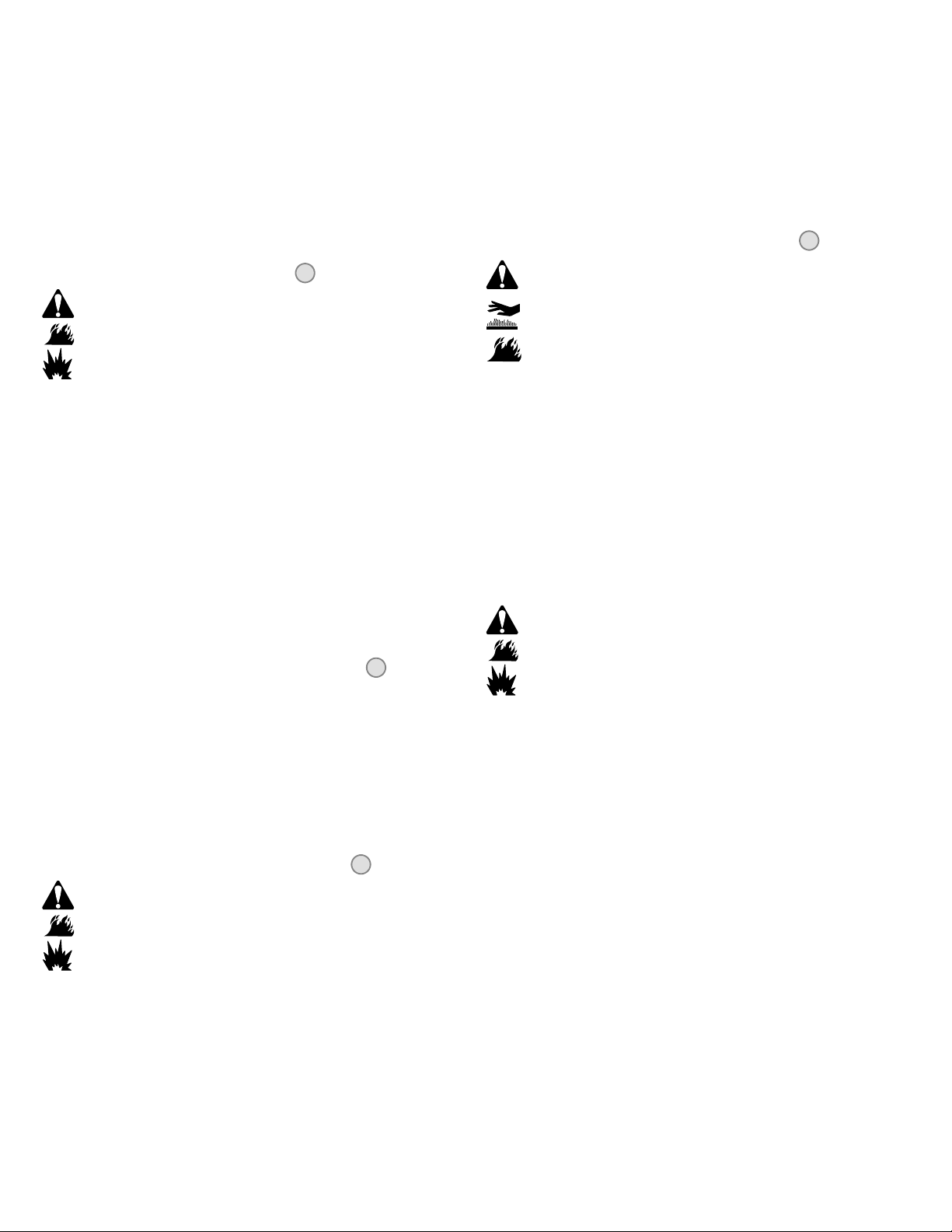

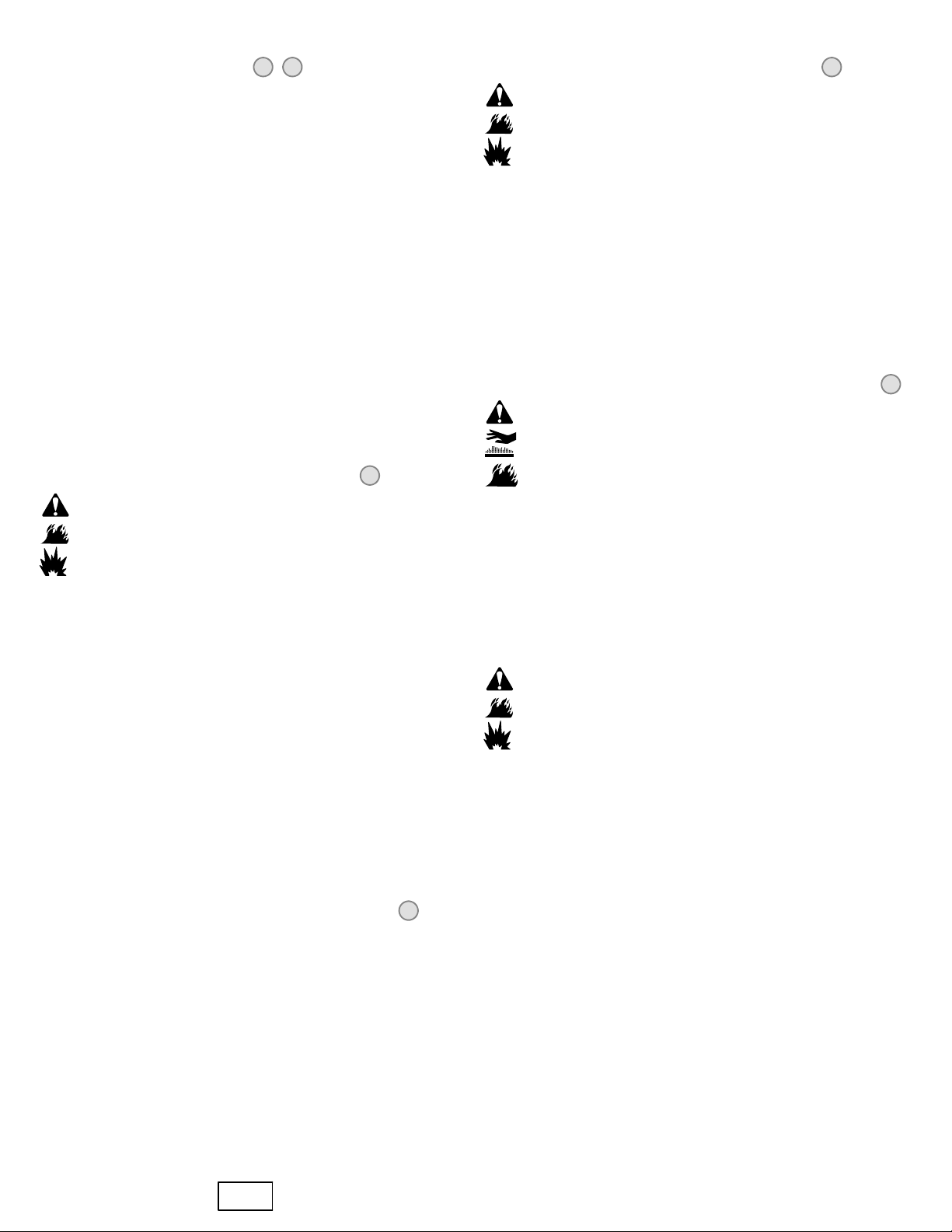

Features and Controls

Compare the illustration

various features and controls.

A. Engine Identification

Model Type Code

B. Spark Plug

C. Fuel Tank and Cap

D. Air Cleaner

E. Starter Cord Handle

F. Oil Fill and Dipstick

G. Oil Drain Plug

H. Muffler

Muffler Guard (optional)

Spark Arrester (optional)

I. Choke Control

J. Throttle Control (optional)

K. Stop Switch

L. Shut-off Valve (optional)

M. Finger Guard

N. Gear Reduction Unit (optional)

1

with your engine to familiarize yourself with the location of

Operation

Oil capacity (see the Specifications section)

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty Certified oils for best

performance. Other high-quality detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

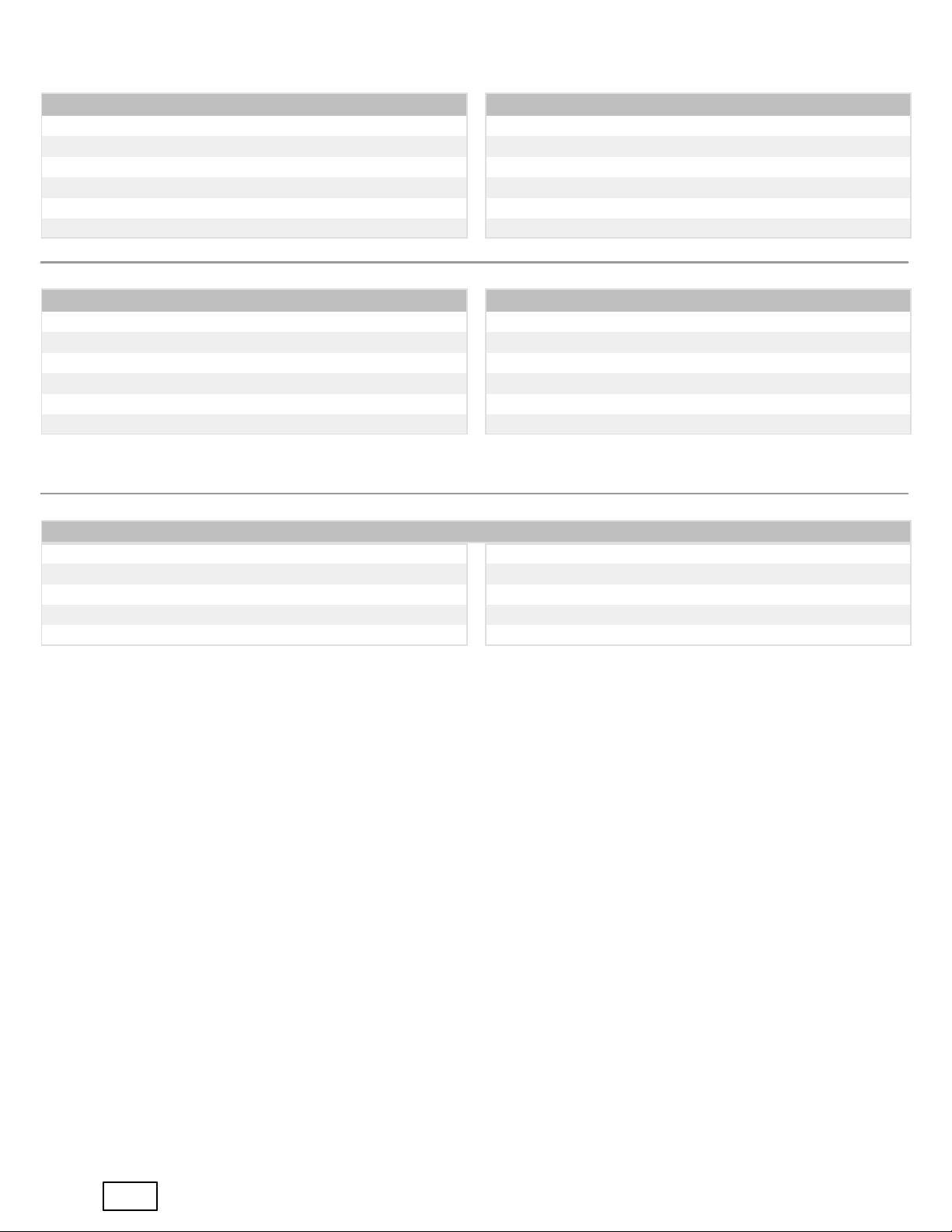

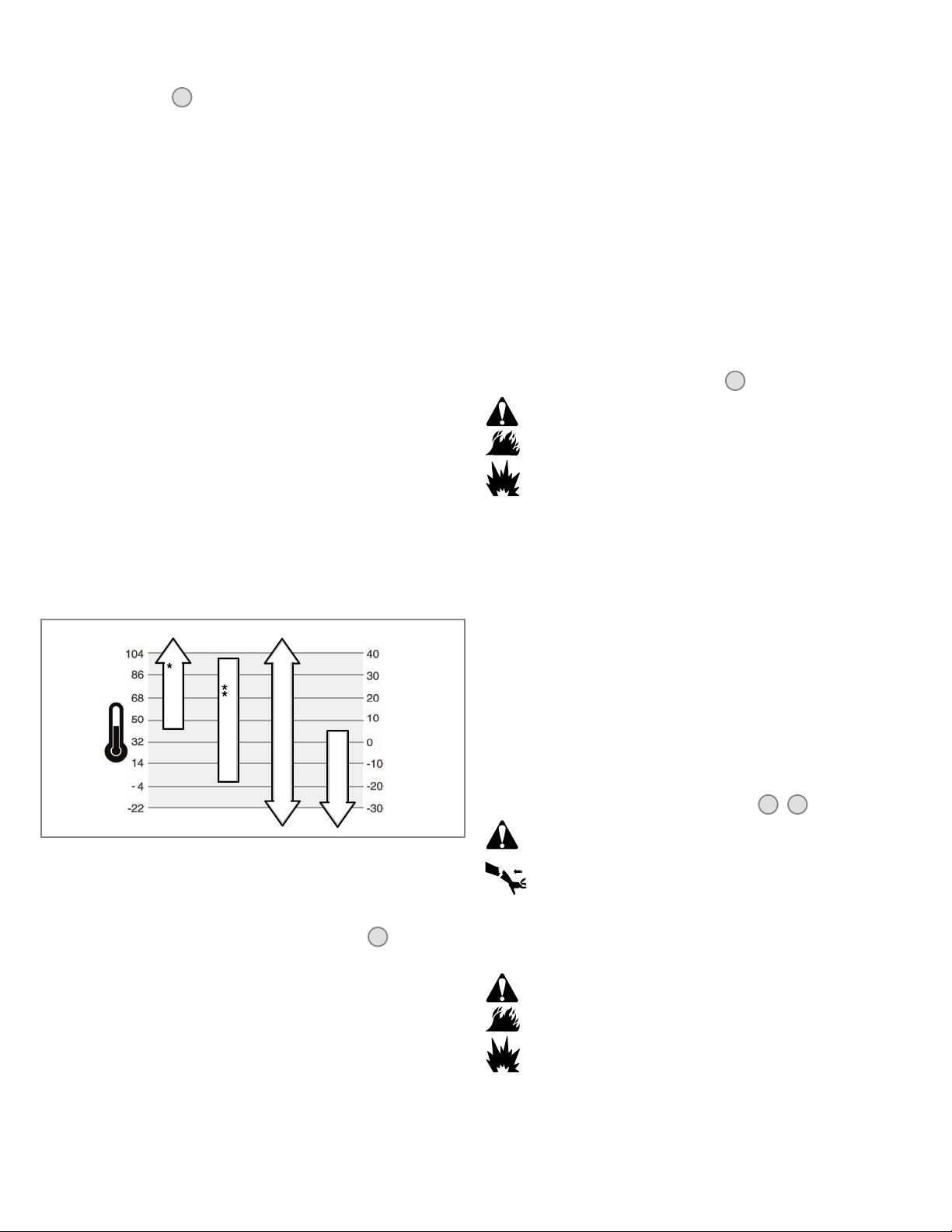

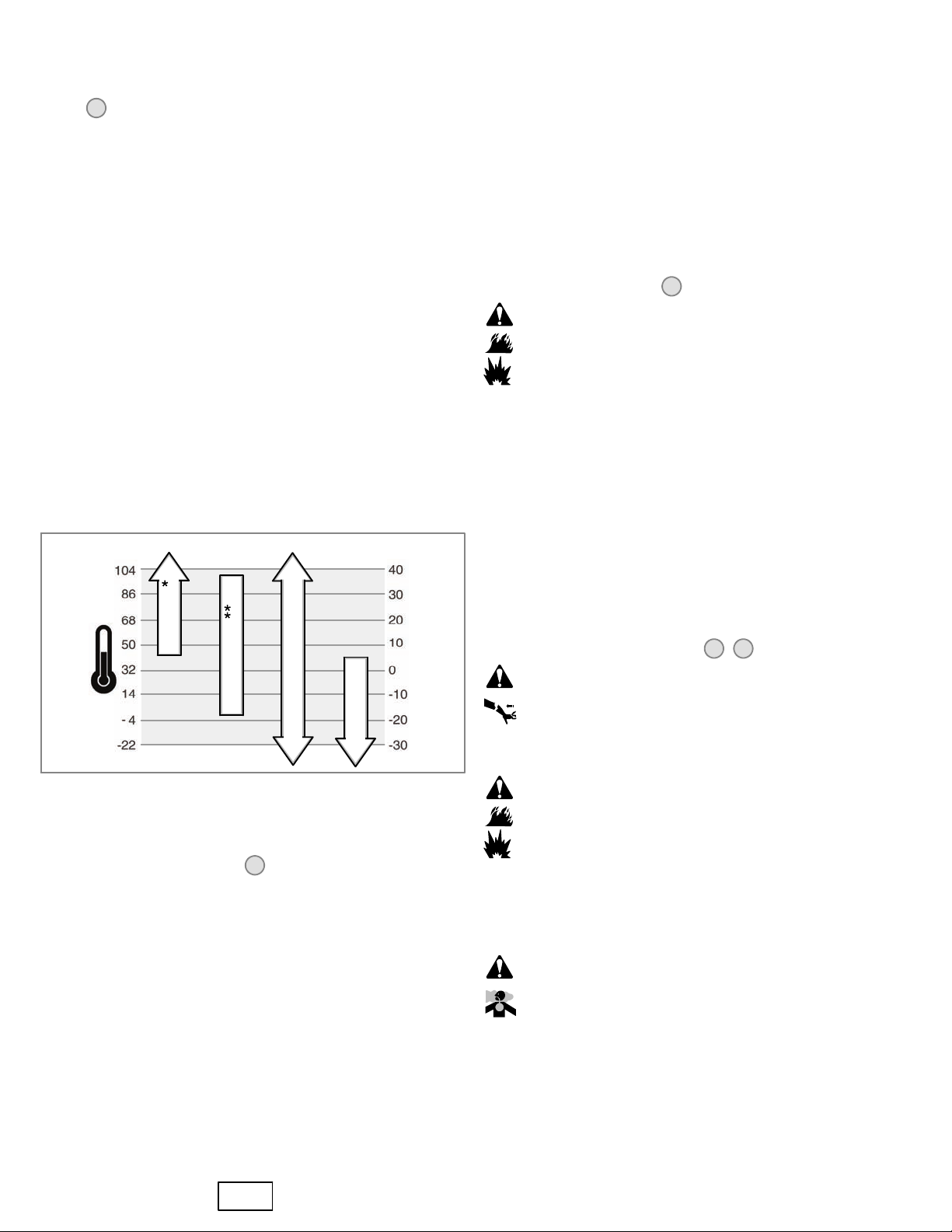

Outdoor temperatures determine the proper oil viscosity for the engine. Use the chart to

select the best viscosity for the outdoor temperature range expected.

°F °C

providers or change brands. This engine is certified to operate on gasoline. The

emissions control system for this engine is EM (Engine Modifications).

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON)

gasoline is acceptable. To remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause decreased performance,

increased fuel consumption, and increased emissions. See a Briggs & Stratton

Authorized Dealer for high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762 meters) with t he high altitude

kit is not recommended.

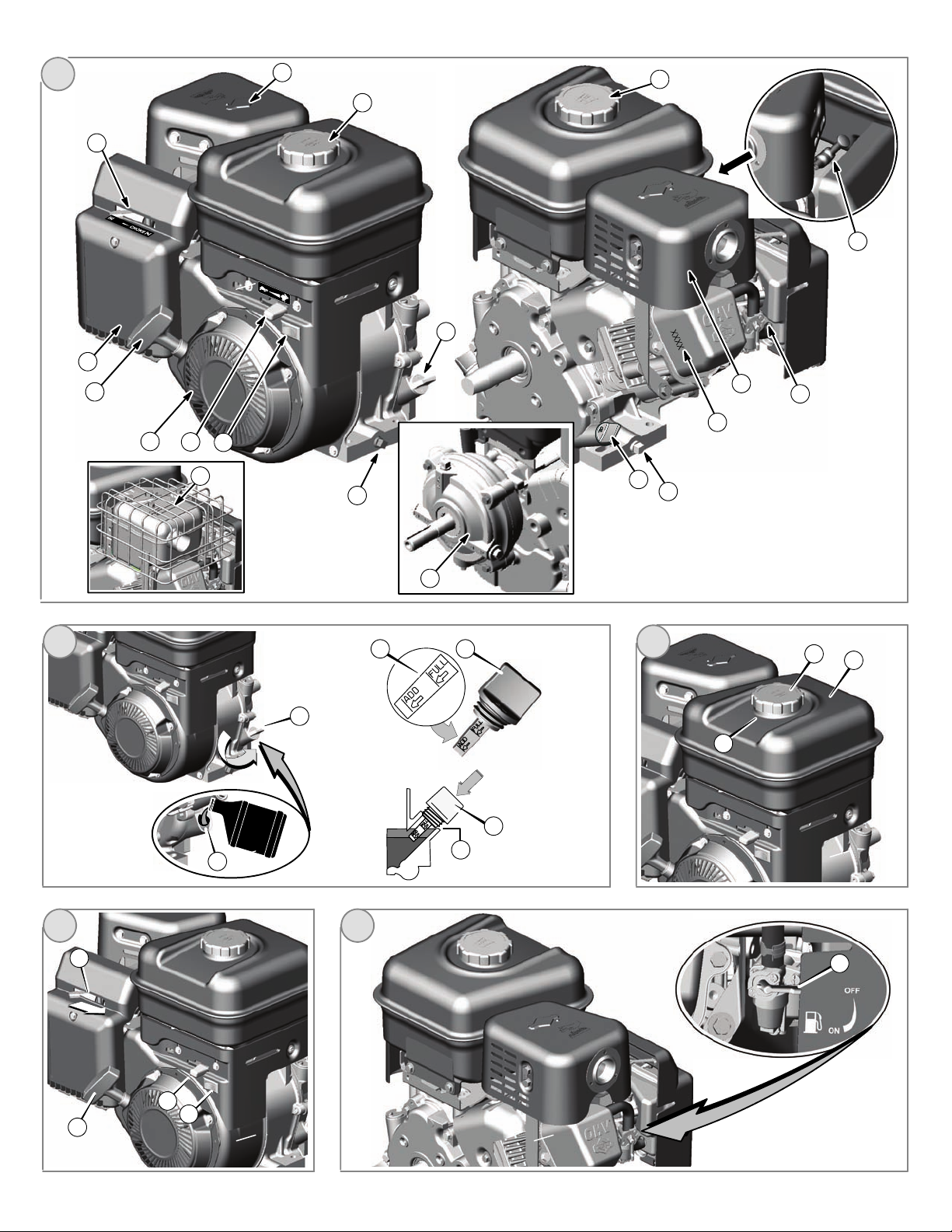

How To Add Fuel — Figure

3

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

• Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill f uel tank. Fill tank to approximately 1.5 inches (38 mm) below top of

neck to allow for fuel expansion.

• Keep gasoline away from sparks, open flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• If fuel spills, wait until it evaporates before starting engine.

1. Clean the fuel cap area of dirt and debris. Remove the fuel cap (A). See Figure 3.

2. Fill the fuel tank (B) with gasoline. To allow for expansion of the gasoline, do not fill

above the bottom of the fuel tank neck (C).

3. Reinstall the fuel cap.

How To Start The Engine — Figure

4 5

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward

SAE 30

10W-30

Synthetic 5W-30

* Below 40°F(4°C) the use of SAE 30 will result in hard starting.

** Above 80°F(27°C) the use of 10W-30 may cause increased oil consumption. Check

oil level more frequently.

How To Check/Add Oil — Figure

Before adding or checking the oil

• Place engine level.

• Clean the oil fill area of any debris.

1. Remove the dipstick (A) and wipe with a clean cloth.

2. Insert the dipstick but do not screw in. Oil level should be at the FULL mark (B)on

the dipstick.

3. To add oil, pour the oil slowly into the engine oil fill (C). Fill to point of overflowing.

4. Replace and tighten the dipstick.

2

5W-30

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) or up to 15% MTBE (methyl tertiary

butyl ether) is acceptable.

CAUTION: Do not use unapproved gasolines, such as E85. Do not mix oil in gasoline or

modify the engine to run on alternate fuels. This will damage the engine components and

void the engine warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See

Storage. All fuel is not the same. If starting or performance problems occur, change fuel

engine faster than you can let go.

Broken bones, fractures, bruises or sprains could result.

• When starting engine, pull the starter cord slowly until resistance is felt and then pull

rapidly to avoid kickback.

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air cleaner are in place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to open/run position, move throttle (if

equipped) to fast position and crank until engine starts.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area, even if doors or windows are open.

CAUTION: This engine was shipped from Briggs & Stratton without oil. Before you start

the engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be covered

under warranty.

1. Check the oil level. See the How To Check/Add Oil section.

2. Make sure equipment drive controls, if equipped, are disengaged. See the equipment

manual for location and operation of these controls.

3. Push the stop switch (A) to the on position (Figure 4).

4. Move the throttle control (B), if equipped, to the fast

engine in the fast

5. Move the choke control (C) to the choke

position.

position.

position. Operate the

6 BRIGGSandSTRATTON.COM

Note: Choke is usually unnecessary when restarting a warm engine.

6. Turn the fuel shut -off valve (D), if equipped, to the on position (Figure 5).

7. Rewind Start: Firmly hold the starter cord handle (E). Pull the starter cord handle

slowly until resistance is felt, then pull rapidly (Figure 4).

Note: If the engine does not start after three attempts, go to

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA).

WARNING: Rapid retraction of the starter cord (kickback) will pull your

hand and arm toward the engine faster than you can let go. Broken bones,

fractures, bruises or sprains could result. When starting engine, pull the starter cord

slowly until resistance is felt and then pull rapidly to avoid kickback.

8. Electric Start: Turn the electric start switch to the on/start position. See the

equipment manual for the location and operation of the switch.

Note: If the engine does not start after three attempts, go to

BRIGGSandSTRATTON.COM or call 1-800-233-3723 (in USA).

CAUTION: To extend the life of the starter, use short starting cycles (five seconds

maximum). Wait one minute between starting cycles.

9. As the engine warms up, move the choke control (C)totherun

(Figure 4).

How To Stop The Engine — Figure

5 6

position

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

Maintenance Chart

First 5 Hours

• Change oil

Every8HoursorDaily

• Check engine oil level

• Clean area around muffler and controls

• Clean finger guard

Every 25 Hours or Annually

• Clean air filter *

• Clean pre-cleaner *

Every 100 Hours or Annually

• Change engine oil

• Check muffler and spark arrester

Every 100 Hours

• Change gear reduction oil (if equipped)

Annually

• Replace air filter

• Replace pre-cleaner

• Replace spark plug

• Clean/Replace fuel filter

• Clean air cooling system *

• Check valve clearance **

* In dusty conditions or when airborne debris is present, clean more often.

** Not required unless engine performance problems are noted.

• Do not choke the carburetor to stop engine.

1. Push the stop switch (A, Figure 6) to the off position

Electric Start: Turn the electric start switch to the off/stop position. See the

equipment manual for the location and operation of the switch.

2. After the engine stops, turn the fuel shut-off valve (D, Figure 5) to the closed position.

or

Maintenance

Use only original equipment replacement parts. Other parts may not perform as

well, may damage the unit, and may result in injury. In addition, use of other parts

may void your warranty.

We recommend that you see any Briggs & Stratton Authorized Dealer for all

maintenance and service of the engine and engine parts.

CAUTION: All t he components used to build this engine must remain in place for proper

operation.

Emissions Control

Maintenance, replacement, or repair of the emissions control devices and systems

may be performed by any non-road engine repair establishment or individual.

However, to obtain “no charge” emissions control service, the work must be performed

by a factory authorized dealer. See the Emissions Warranty.

WARNING

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation,

or laceration.

Fire hazard

Carburetor Adjustment

Never make adjustments to the carburetor. The carburetor was set at the factory to

operate efficiently under most conditions. However, if adjustments are required, see any

Briggs & Stratton Authorized Dealer for service.

CAUTION: The manufacturer of the equipment on which this engine is installed specifies

the top speed at which the engine will be operated. Do not exceed this speed.

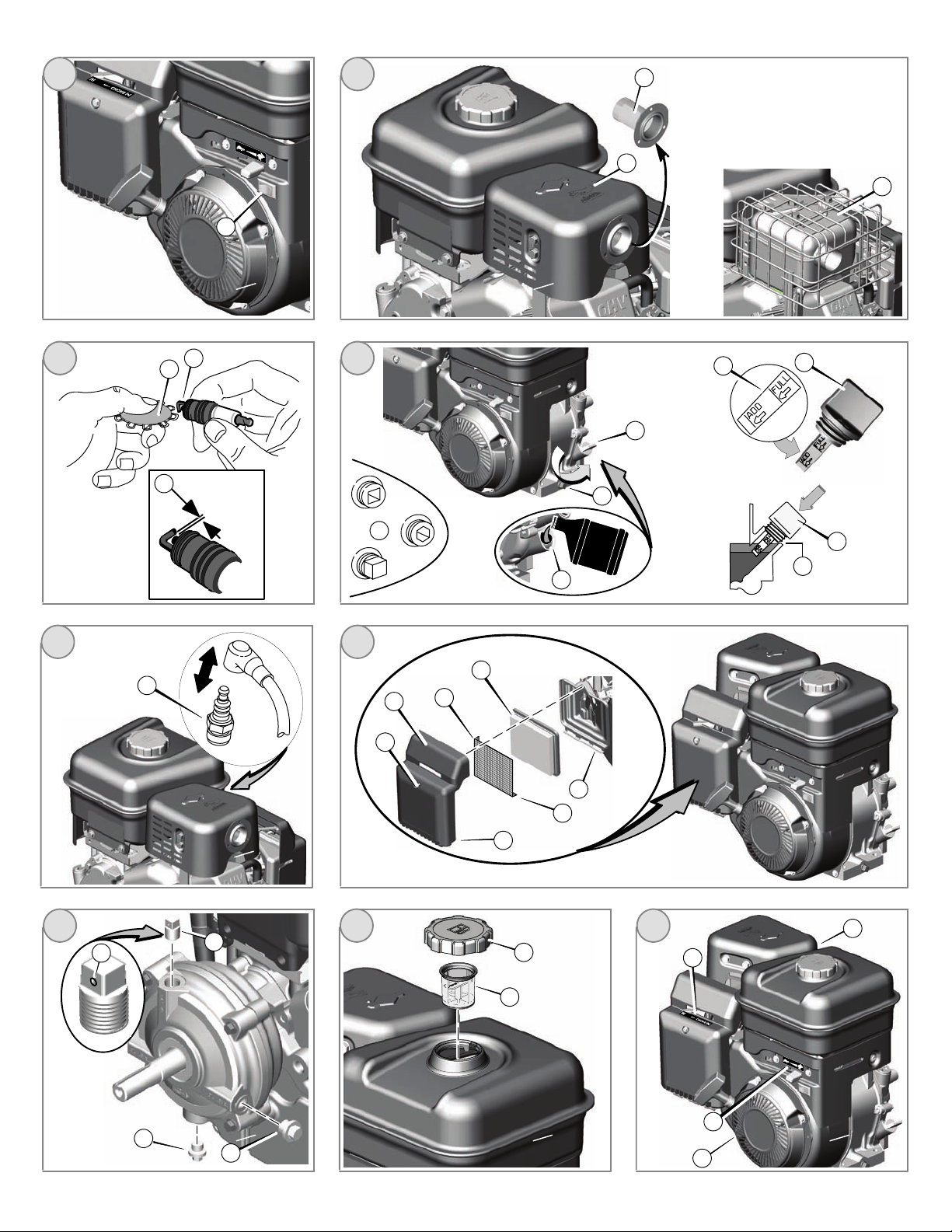

How To Check The Spark Plug — Figure

Check the gap (A, Figure

and tighten the spark plug to the recommended torque. For gap setting or torque, see the

Specifications section.

Note: In some areas, local law requires using a resistor spark plug to suppress ignition

signals. If this engine was originally equipped with a resistor spark plug, use the same

type for replacement.

Inspect Muffler And Spark Arrester — Figure

8

7

WARNING

Running engines produce heat. Engine parts, especially muffler, become

extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

• Install and maintain in working order a spark arrester before using equipment on

forest-covered, grass-covered, brush-covered unimproved land. The state of

California requires this (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal land.

Inspect the muffler (A, Figure 7) for cracks, corrosion, or other damage. Remove the

spark arrester (B), if equipped, and inspect for damage or carbon blockage. If

replacement parts are required, make sure to use only original equipment replacement

parts.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from the spark plug.

• Use only correct tools.

• Do not tamper with governor spring, links or other parts to increase engine speed.

• Replacement parts must be the same and installed in the same position as the

original parts.

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

en

WARNING: Replacement parts must be the same and installed in the same

position as the original parts or fire could result.

How To Change The Oil — Figure

CAUTION: Used oil is a hazardous waste product and must be disposed of properly. Do

not discard with household waste. Check with your local authorities, service center, or

dealer for safe disposal/recycling facilities.

9 10

Remove Oil

1. With engine off but still warm, disconnect the spark plug wire (A) and keep it away

from the spark plug (Figure 10).

7

2. Remove the oil drain plug (B, Figure 9). Drain the oil into an approved receptacle.

Note: Any of the oil drain plugs (C) shown may be installed in the engine.

3. After the oil has drained, install and tighten the oil drain plug.

Add oil

• Place engine level.

• Clean the oil fill area of any debris.

• See the Specifications section for oil capacity.

1. Remove the dipstick (D) and wipe with a clean cloth.

2. Pour the oil slowly into the engine oil fill (E). Fill to point of overflowing.

3. Install the dipstick but do not screw in. Remove and check the oil level. Oil level

should be at the FULL mark (F) on the dipstick.

4. Install and tighten the dipstick.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

• Before replacing the fuel filter, drain the fuel tank or close the fuel shut-off valve.

• Replacement parts must be the same and installed in the same position as the

original parts.

• If fuel spills, wait until it evaporates before starting engine.

1. Remove the fuel cap (A, Figure 13).

2. Remove the fuel filter (B).

3. If the fuel filter is dirty, clean or replace it. If you replace the fuel filter, make sure to

use an original equipment replacement filter.

How To Clean The Air Cooling System — Figure

14

How To Service The Air Filter — Figure

11

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

• Never start or run the engine with the air cleaner assembly or the air filter removed.

CAUTION: Do not use pressurized air or solvents to clean the filter. Pressurized air can

damage the filter and solvents will dissolve the filter.

The air cleaner system uses a pleated filter with an optional pre-cleaner. The pre-cleaner

can be washed and reused.

Flat Air Filter

1. Loosen the fastener (D) that holds the cover (A). See Figure 11.

2. Open the cover and remove the pre-cleaner (C) and the filter (B).

3. To loosen debris, gently tap the filter on a hard surface. If the filter is excessively

dirty, replace with a new filter.

4. Wash the pre-cleaner in liquid detergent and water. Then allow it to thoroughly air

dry. Do not oil the pre-cleaner.

5. Assemble the dry pre-cleaner to the filter with the lip (G) of the pre-cleaner on the

bottom of the filter pleats.

6. Install the filter.

7. Install the cover tabs (E) into the slots (F).

8. Close the cover and secure with the fastener.

How To Change The Gear Reduction Oil — Figure

If your engine is equipped with a gear reduction unit, service as follows.

1. Remove the oil fill plug (B) and the oil level plug (C).

2. Remove the oil drain plug (A, Figure 12) and drain the oil into an appropriate

receptacle.

3. Install and tighten the oil drain plug.

4. To refill, slowly pour gear lube into the oil fill hole (see Specifications section).

Continue to pour until the oil runs out of the oil level hole.

5. Install and tighten the oil level plug.

6. Install and tighten the oil fill plug.

Important: The oil fill plug has a vent hole (D) and must be installed on the top of the

gear case cover as shown.

How To Clean/Replace The Fuel Filter — Figure

12

13

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

WARNING

Running engines produce heat. Engine parts, especially muffler, become

extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool before touching.

• Remove accumulated debris from muffler area and cylinder area.

CAUTION: Do not use water to clean the engine. Water could contaminate the fuel

system. Use a brush or dry cloth to clean the engine.

This is an air cooled engine. Dirt or debris can restrict air flow and cause the engine to

overheat, resulting in poor performance and reduced engine life.

Use a brush or dry cloth to remove debris from the finger guard (A). Keep linkage,

springs and controls (B) clean. Keep the area around and behind the muffler (C)freeof

any combustible debris (Figure 14).

After a period of time, debris can accumulate in the cylinder cooling fins and cause the

engine to overheat. This debris cannot be removed without partial disassembly of the

engine. Have a Briggs & Stratton Authorized Dealer inspect and clean the air cooling

system as recommended in the Maintenance Chart.

Storage

WARNING

Gasoline and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Storing Gasoline Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters or other appliances that have pilot

lights or other ignition sources because they can ignite gasoline vapors.

Fuel System

Fuel can become stale when stored over 30 days. Stale fuel causes acid and gum

deposits to form in the fuel system or on essential carburetor parts. To keep fuel fresh,

use Briggs & Stratton FRESH START

drip concentrate cartridge.

There is no need to drain gasoline from the engine if a fuel stabilizer is added according

to instructions. Run the engine for 2 minutes to circulate the stabilizer throughout the fuel

system. The engine and fuel can then be stored up to 24 months.

If gasoline in the engine has not been treated with a fuel stabilizer, it must be drained into

an approved container. Run the engine until it stops from lack of fuel. The use of a fuel

stabilizer in the storage container is recommended to maintain freshness.

Engine Oil

While the engine is still warm, change the engine oil.

®

fuel stabilizer, available as a liquid additive or a

• Keep gasoline away from sparks, open flames, pilot lights, heat, and other ignition

sources.

8

Troubleshooting

Need Assistance? Go to BRIGGSandSTRATT ON.COM or call 1-800-233-3723.

BRIGGSandSTRATTON.COM

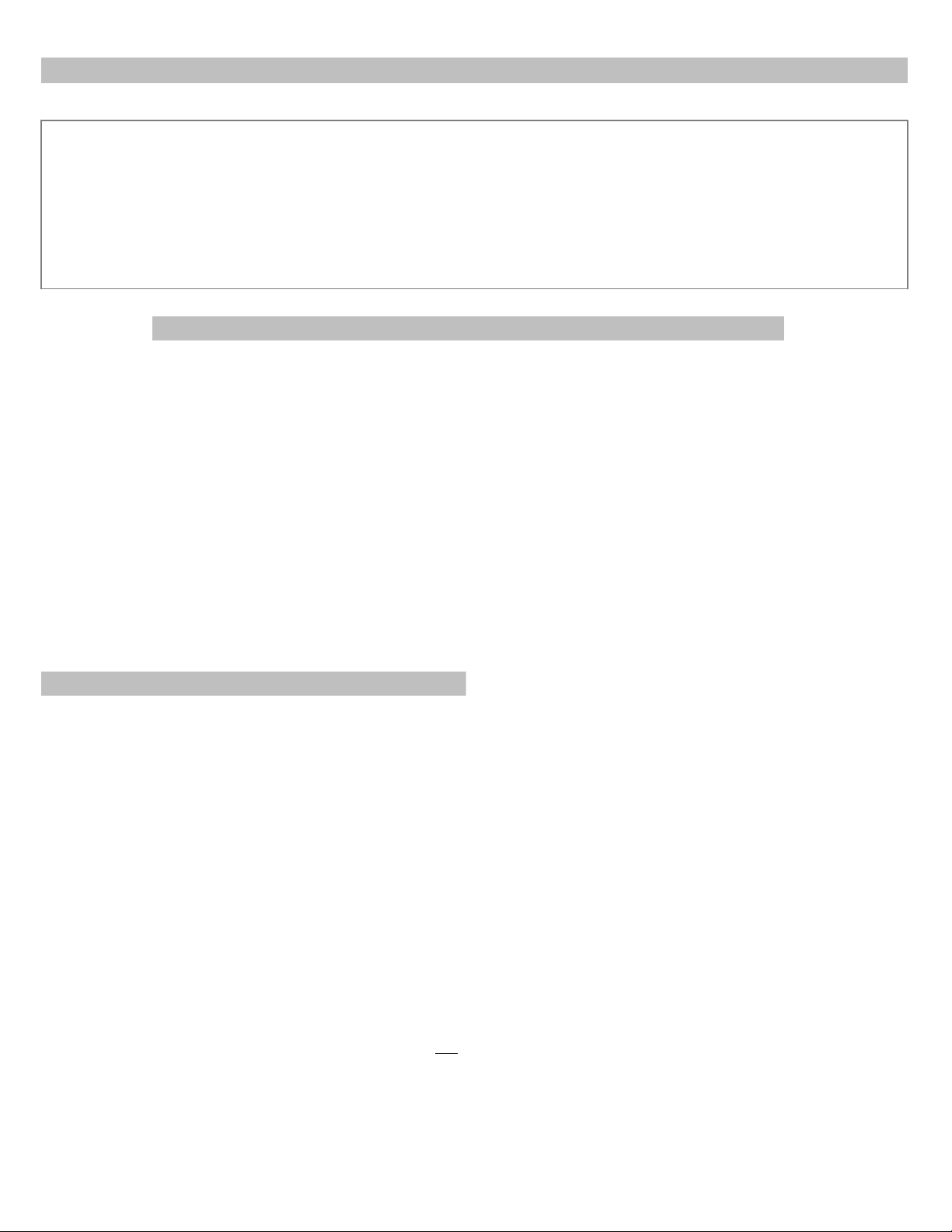

Specifications

Engine Specifications

Model 120000

Displacement 12.48 ci (205 cc)

Bore 2.688 in (68.28 mm)

Stroke 2.200 in (55.88 mm)

Oil Capacity 18 — 20 oz (0.54 — 0.59 L)

Gear Reduction Oil 80W-90

Tune-up Specifications *

Model 120000

Spark Plug Gap 0.030 in (0.76 mm)

Spark Plug Torque 180 lb-in (20 Nm)

Armature Air Gap 0.010 — 0.014 in (0.25 — 0.36 mm)

Intake Valve Clearance 0.004 — 0.006 in (0.10 — 0.15 mm)

Exhaust Valve Clearance 0.009 — 0.011 in (0.23 — 0.28 mm)

* Engine power will decrease 3.5% for each 1,000 feet (300 meters) above sea level and 1% for each 10° F(5.6° C) above 77° F(25° C). The engine will operate satisfactorily at an

angle up to 15°. Refer to the equipment operator’s manual for safe allowable operating limits on slopes.

Engine Specifications

Model 200000

Displacement 18.63 ci (305 cc)

Bore 3.120 in (79.24 mm)

Stroke 2.438 in (61.93 mm)

Oil Capacity 26 — 28 oz (0.77 — 0.83 L)

Gear Reduction Oil SAE 30

Tune-up Specifications *

Model 200000

Spark Plug Gap 0.030 in (0.76 mm)

Spark Plug Torque 180 lb-in (20 Nm)

Armature Air Gap 0.008 — 0.012 in (0.20 — 0.30 mm)

Intake Valve Clearance 0.004 — 0.006 in (0.10 — 0.15 mm)

Exhaust Valve Clearance 0.009 — 0.011 in (0.22 — 0.28 mm)

Common Service Parts n

Service Part Part Number

Flat Air Filter 491588, 5043

Flat Air Filter Pre-cleaner 493537, 5064

Fuel Filter 792917

Fuel Additive 5041, 5058

n We recommend that you see any Briggs & Stratton Authorized Dealer for all maintenance and service of the engine and engine parts. Use only genuine Briggs & Stratton parts.

Service Part Part Number

Resistor Spark Plug 491055

Long Life Platinum Spark Plug 5066

Spark Plug Wrench 89838, 5023

Spark Tester 19368

en

9

BRIGGS & STRATTON ENGINE OWNER WARRANTY POLICY

May 2008

LIMITED WARRANTY

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) of the engine that is defective in material or workmanship or both. Transportation charges on

product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and is subject to the time periods and conditions

stated below. For warranty service, find the nearest Authorized Servic e Dealer in our dealer locator map at BRIGGSandSTRATTON.COM, or by calling

1-800-233-3723, or as listed in the ‘Yellow Pagest’.

There is no other expressed warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one year from

purchase, or to the extent permitted by law and all implied warranties are excluded. Liability for incidental or consequential damages are excluded to the extent

exclusion is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state and country to country.

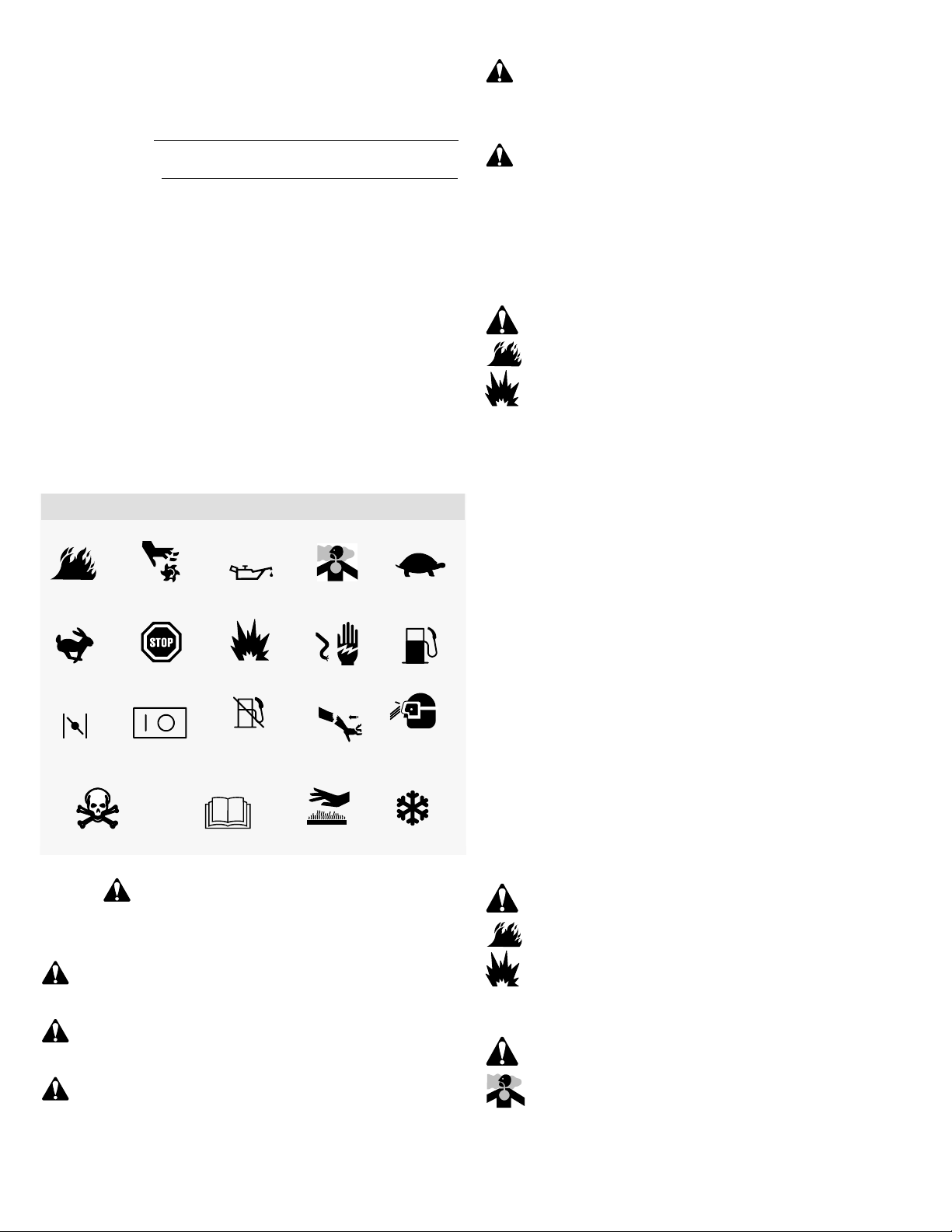

STANDARD WARRANTY TERMS *

Brand/Product Type

Vanguardt

Extended Life Seriest, I/C®, Intekt I/C®, Intekt Pro

Snow Series MAXt with Du ra-Boret Cast Iron Sleeve

Consumer Use Commercial Use

2 years 2 years

2 years 1 year

2 years 1 year

Y

All Other Briggs & Stratton Engines 2 years 90 days

* These are our standard warranty terms, but occasionally there may be additional warranty coverage that was not determined at time of publication. For a listing of current

warranty terms for your engine, go to BRIGGSandSTRATTON.COM or contact your Authorized Briggs & Stratton Service Dealer.

Y

Engines used on Home Standby Generator applications are warranted under consumer use only. This warranty does not apply to engines on equipment used for prime

power in place of a utility. Engines used in competitive racing or on commercial or rental tracks are not warranted.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the table above. “Consumer

use” means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes.

Once an engine has experienced commercial use, it shall thereafter be considered as a commercial use engine for purposes of this warranty.

No warranty registration is necessary to obtain warranty on Briggs & Stratton Products. Save your proof of purchase receipt. If you do not provide proof of the initial

purchase date at the time warranty service is requested, the manufacturing date of the product will be used to determine the warranty period.

About Your Warranty

Briggs & Stratton welcomes warranty repair and apologizes to you for being

inconvenienced. Any Authorized Service Dealer may perform warranty repairs. Most

warranty repairs are handled routinely, but sometimes requests for warranty service may

not be appropriate.

If a customer differs with the decision of the Service Dealer, an investigation will be made

to determine whether the warranty applies. Ask the Service Dealer to submit all

supporting facts to his Distributor or the Factory for review. If the Distributor or the

Factory decides that the claim is justified, the customer will be fully reimbursed for those

items that are defective. To avoid misunderstanding which might occur between the

customer and the Dealer, listed below are some of the causes of engine failure that the

warranty does not cover.

Normal wear: Engines, like all mechanical devices, need periodic parts service and

replacement to perform well. Warranty will not cover repair when normal use has

exhausted the life of a part or an engine. Warranty would not apply if engine damage

occurred because of misuse, lack of routine maintenance, shipping, handling,

warehousing or improper installation. Similarly, warranty is void if the serial number of the

engine has been removed or the engine has been altered or modified.

Improper maintenance: The life of an engine depends upon the conditions under which

it operates, and the care it receives. Some applications, such as tillers, pumps and rotary

mowers, are very often used in dusty or dirty conditions, which can cause what appears

to be premature wear. Such wear, when caused by dirt, dust, spark plug cleaning grit, or

other abrasive material that has entered the engine because of improper maintenance, is

not covered by warranty.

This warranty covers engine related defective material and/or workmanship only

and not replacement or refund of the equipment to which the engine may be

mounted. Nor does the warranty extend to repairs required because of:

1 Problems caused by parts that are not original Briggs & Stratton parts.

2 Equipment controls or installations that prevent starting, cause unsatisfactory engine

performance, or shorten engine life. (Contact equipment manufacturer.)

3 Leaking carburetors, clogged fuel pipes, sticking valves, or other damage, caused

by using contaminated or stale fuel.

4 Parts which are scored or broken because an engine was operated with insufficient

or contaminated lubricating oil, or an incorrect grade of lubricating oil (check and

refill when necessary, and change at recommended intervals). OIL GARD may not

shut down running engine. Engine damage may occur if oil level is not properly

maintained.

5 Repair or adjustment of associated parts or assemblies such as clutches,

transmissions, remote controls, etc., which are not manufactured by Briggs &

Stratton.

6 Damage or wear to parts caused by dirt, which entered the engine because of

improper air cleaner maintenance, re-assembly, or use of a non-original air cleaner

element or cartridge. At recommended intervals, clean and/or replace the filter as

stated in the Operator’s Manual.

7 Parts damaged by over-speeding, or overheating caused by grass, debris, or dirt,

which plugs or clogs the cooling fins, or flywheel area, or damage caused by

operating the engine in a confined area without sufficient ventilation. Clean engine

debris at recommended intervals as stated in the Operator’s Manual.

8 Engine or equipment parts broken by excessive vibration caused by a loose engine

mounting, loose cutter blades, unbalanced blades or loose or unbalanced impellers,

improper attachment of equipment to engine crankshaft, over-speeding or other

abuse in operation.

9 A bent or broken crankshaft, caused by striking a solid object with the cutter blade of

a rotary lawn mower, or excessive v-belt tightness.

10 Routine tune-up or adjustment of the engine.

,

11 Engine or engine component failure, i.e., combustion chamber, valves, valve seats,

valve guides, or burned starter motor windings, caused by the use of alternate fuels

such as, liquified petroleum, natural gas, altered gasolines, etc.

Warranty service is available only through authorized service dealers by Briggs &

Stratton Corporation. Locate your nearest Authorized Service Dealer in our dealer

locator map on BRIGGSandSTRATT ON .COM or by calling 1-800-233-3723, or as

listed in the ‘Yellow Pagest’.

10 BRIGGSandSTRATTON.COM

Emissions Control System Warranty Statement

Briggs & Stratton Corporation (B&S), the California Air Resources Board (CARB) and the United States Environmental Protection

Agency (U.S. EPA) Emissions Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

California, United States and Canada Emissions Control Defects

Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and B&S are pleased to explain

the Emissions Control System Warranty on your small off-road engine (SORE). In

California, new small off-road engines model year 2006 and later must be designed, built

and equipped to meet the State’s stringent anti-smog standards. Elsewhere in the United

States, new non-road, spark-ignition engines certified for model year 1997 and later must

meet similar standards set forth by the U.S. EPA. B&S must warrant the emissions

control system on your engine for t he periods of time listed below, provided there has

been no abuse, neglect or improper maintenance of your small off-road engine.

Your emissions control system includes parts such as the carburetor, air cleaner, ignition

system, fuel line, muffler and catalytic converter. Also included may be connectors and

other emissions related assemblies.

Where a warrantable condition exists, B&S will repair your small off-road engine at no

cost to you including diagnosis, parts and labor.

Briggs & Stratton Emissions Control Defects Warranty Coverage

Small off-road engines are warranted relative to emissions control parts defects for a

period of two years, subject to provisions set forth below. If any covered part on your

engine is defective, the part will be repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for the performance of the

required maintenance listed in your Operating and Maintenance Instructions. B&S

recommends that you retain all your receipts covering maintenance on your small

off-road engine, but B&S cannot deny warranty solely for the lack of receipts or for your

failure to ensure the performance of all scheduled maintenance.

As the small off-road engine owner, you should however be aware that B&S may deny

you warranty coverage if your small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your small off-road engine to an Authorized B&S

Service Dealer as soon as a problem exists. The undisputed warranty repairs should be

completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact a B&S Service Representative at (414) 259-5262.

The emissions warranty is a defects warranty. Defects are judged on normal engine

performance. The warranty is not related to an in-use emissions test.

Briggs & Stratton Emissions Control Defects Warranty Provisions

The following are specific provisions relative to your Emissions Control Defects Warranty Coverage. It is in addition to the B&S engine warranty f or non-regulated engines found in the

Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the engine

purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive valves and switches

• Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser that the Warranted

Parts shall be free from defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years from the date the engine is

delivered to a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be performed at no charge to the

owner, including diagnostic labor which leads to the determination that a Warranted

Part is defective, if the diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty service contact your nearest Authorized B&S

Service Dealer as listed in the “Yellow Pages” under “Engines, Gasoline,” “Gasoline

Engines,” “Lawn Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of the B&S Engine

Warranty Policy. Warranty coverage shall be excluded for failures of Warranted

Parts which are not original B&S parts or because of abuse, neglect or improper

maintenance as set forth in the B&S Engine Warranty Policy. B&S is not liable to

cover failures of Warranted Parts caused by the use of add-on, non-original, or

modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as required

maintenance or which is scheduled only for regular inspection to the effect of “repair

or replace as necessary” shall be warranted as to defects for the warranty period.

Any Warranted Part which is scheduled for replacement as required maintenance

shall be warranted as to defects only for the period of time up to the first scheduled

replacement for that part. Any replacement part that is equivalent in performance

and durability may be used in the performance of any maintenance or repairs. The

owner is responsible for the performance of all required maintenance, as defined in

the B&S Operating and Maintenance Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine components caused

by the failure of any Warranted Part still under warranty.

Look For Relevant Emissions Durability Period and Air Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Emissions

Standard must display information regarding the Emissions Durability Period and the Air

Index. Briggs & Stratton makes this information available to the consumer on our

emissions labels. The engine emissions label will indicate certification information.

The Emissions Durability Period describes the number of hours of actual running time

for which the engine is certified to be emissions compliant, assuming proper

maintenance in accordance with the Operating & Maintenance Instructions. The

following categories are used:

Moderate:

Engine is certified to be emissions compliant for 125 hours of actual engine running time.

Intermediate:

Engine is certified to be emissions compliant for 250 hours of actual engine running time.

en

Extended:

Engine is certified to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with an intermediate rating

would equate to 10 to 12 years.

Briggs & Stratton engines are certified to meet the United States Environmental

Protection Agency (USEPA) Phase 2 emissions standards. For Phase 2 certified

engines, the Emissions Compliance Period referred to on the Emissions Compliance

label indicates the number of operating hours for which the engine has been shown to

meet Federal emissions requirements.

For engines less than 225 cc displacement.

Category C = 125 hours , Category B = 250 hours , Category A = 500 hours

For engines of 225 cc or more displacement.

Category C = 250 hours , Category B = 500 hours , Category A = 1000 hours

11

Общи сведения

За ˜езе˜вни …асти или техни…еска помощ запиμете по-долу номе˜ата на модела,

типа и кода на двигател ви, заедно с датата на купуването. ‚ези номе˜а се

нами˜ат въ˜ху двигател ви (ви¥те ст˜аницата Показатели и управления).

Дата на купуване:

MM/ÄÄ/øøøø

ВНИМАНИЕ, използвано áåç п˜едуп˜едителни символ, посо…ва

ситуаци,êîòî би могла да доведе до повреждане на продукта.

ПРЕДУПРЕЖДЕНИЕ

¤зго˜елите газове от този двигател съдъ˜¥ат хими…ески съединени,

известни на щата яалифо˜ни като п˜и…инители на ˜ак, ув˜е¥дани ï˜è

˜à¥äàíå, èëè ä˜óãè óâ˜å¥äàíè, свъ˜зани с ˜еп˜одуктивността.

Модел на двигателя:

flîäåë: ÿîä:‚èï:

Информация за номиналната мощност на двигателите

fiълната мощност въ˜ху отделните модели бензинови двигатели е отбелçàíà â

съответствие със създадени от SAE (Д˜у¥ество на ин¥ене˜ите от

автомобилната п˜омиμленост и т˜анспо˜та) fi˜авилник за техни…еска

експлоатаци J1940 (flетодика за оп˜еделне на номиналната мощност и

âú˜òùè момент на малки двигатели), а номиналната им мощност бе полу…ена и

ко˜иги˜ана в съответствие с ве˜сиòà íà fi˜авилника за техни…еска

експлоатаци J1995 на SAE (ˆедакци от 2002-05 г.). Стойностите на въ˜тùè

момент са изведени п˜и 3060 об/мин.; стойностите на мощността √ п˜и 3600

об/мин. Действителната пълна мощност на двигателите ще бъде по-ниска и се

влие, ме¥ду д˜угото, от околната с˜еда, в кото обо˜удването се експлоати˜а и

от ха˜акте˜истиките на всеки отделен двигател. fi˜è μè˜îêè íàáî˜ îò ìàμини,

въ˜ху които се поставт двигателите и п˜и ˜азнооб˜азието на екологи…ните

изисквани,âêîто обо˜удването ˜аботи, бензиновит двигател нма да ˜азвие

указаната от п˜оизводител пълна мощност, когато е монти˜ан на дадено

ене˜гийно обо˜удване (действителната мощност ∆на обекта∆ или ефективната

мощност). ‚ази ˜азлика се дъл¥и на голм б˜ой факто˜и, вкл˚…ително на

аксесоа˜ите към двигател (въздуμен филтъ˜, ауспух, система за за˜е¥дане,

система за охла¥дане, ка˜бу˜ато˜, го˜ивна помпа и т. н.), на ха˜акте˜ните

ог˜ани…ени за използването му, на условита в околната с˜еда, в кото

двигателт ˜аботи (темпе˜ату˜а, вла¥ност, надмо˜ска висо…ина), на ˜азли…и

във всеки отделен двигател. fiо˜ади технологи…ни и п˜оизводствени ог˜ани…ени

фи˜мата Briggs & Stratton мо¥е да замести даден двигател с по-висока

номинална мощност с двигател от тези се˜ии.

òà

Техника за безопасност на оператора

СИМВОЛИ ЗА БЕЗОПАСНОСТ И УПРАВЛЕНИЕ

Движещи

Огнеопасно

Ñòîï

Âêë. Èçêë.

Опасни

химикали

fi˜едуп˜едителнит символ за опасност

èíôî˜ìàöè за ˜искове, които могат да доведат до на˜анване на пе˜сонала.

Сигнализи˜аща дума (›fiæÑ‹›, fiˆÅćfiˆÅ≠ÄÅ‹¤Å èëè ◊‹¤fl拤Е) се постав

заедно с п˜едуп˜едителен символ, за да посо…и ве˜отността и потенциалната

се˜иозност на на˜анването. Допълнително, един символ за опасност мо¥е да

показва вида на опасността.

се части

Взривоопасно

Прекратяване

подаването на гориво

Прочетете

Ръководството

Масло

Опасност за поражения

от електрически ток

ОПАСНО посо…ва опасност, кото, ако не бъде избегната, ще доведе

до смърт или сериозно нараняване.

ПРЕДУПРЕЖДЕНИЕ посо…ва опасност, коòî, àêî íå áúäå

избегната, може да доведе до смърт или сериозно нараняване.

ВНИМАНИЕ посо…ва опасност, кото ако не бъде избегната, може да

доведе до малка или средна степен на нараняване.

Отровни

газове

Обратен

óäàð

Гореща

повърхност

îï˜åäåë п˜едох˜анителна

Бързи

обороти

Гориво

Да се носят

предпазни очила

измръзването

Бавни

обороти

Смукач

ПРЕДУПРЕЖДЕНИЕ

ÿî˜ïî˜àöè Briggs & Stratton íå îäîá˜ваинепозволва използването на

тези двигатели въ˜ху всъдеходи на 3 колела (ATVs), мотоциклети,

увеселителни коли…ки/за ка˜тинг, летателни апа˜ати или т˜анспо˜тни

с˜едства за у…астие в състезателни ме˜оп˜иòè. ¤зползването на тези

двигатели на такива маμини мо¥е да доведе до мате˜иални щети,

се˜иозни на˜анâàíè (âêë˚…ително па˜ализа) и до˜и до смъ˜т.

ВНИМАНИЕ: ‹àñòîùèт двигател се достав от Briggs & Stratton без масло.

fi˜еди да ста˜ти˜ате двигател се уве˜ете, …е сте налели масло спо˜ед

инст˜укциите в това ˜ъководство. жко го ста˜ти˜ате без масло, той ще се

пов˜еди, без да мо¥е да бъде поп˜авен и га˜анциòà íìà äà ãî ïîê˜èâà.

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

При доливане на гориво

• ¤çêë˚…ете двигател и го оставете да се охлади най-малко 2 минути, п˜еди

да свалите капа…ката на ˜езе˜воа˜а за го˜иво.

• fiълнете ˜езе˜воа˜а за го˜иво на отк˜ито или в доб˜е вентили˜ано

помещение.

• ‹е п˜епълвайте ˜езе˜воа˜а за го˜иво. fiълнете го п˜иблизително 1,5 ин…а

(38 mm) по-ниско от го˜ни ˜ъб на гъ˜ловината, за да позволите ˜азμи˜ение

на го˜ивото.

• Д˜ъ¥те бензина дале… от иск˜и, отк˜ити пламъци, сигнални лампи, топлина

и д˜уги запалителни изто…ници.

• fi˜îâå˜вайте …есто го˜ивоп˜оводите, ˜езе˜воа˜а, капа…ката и

съединенита за пукнатини и те…ове. Замен йте ги ако е необходимо.

• жко го˜ивото се ˜азлее, из…акайте докато то се изпа˜и, п˜еди да ста˜ти˜ате

двигател.

При стартиране на двигателя

• ‡ве˜ете се, …е запалителната свещ, μумозаглуμèòåë, êàïà…êàòà íà

˜езе˜воа˜а за го˜иво и въздуμíè филтъ˜ (ако има такъв) са на мстото си и

са обезопасени.

• ‹е ˜азвъ˜тайте двигател с извадена запалителна свещ.

• жко двигателт се задави, поставете смука…а (ако има такъв) на позици

OPEN/RUN, п˜еместете ˜ъ…ната газ (ако има такава) на позици FAST и

˜азвъ˜тайте, докато двигателò ñòà˜òè˜à.

При работеща машина

• ‹е накланйте двигател èëè ìàμината под ъгъл, който води до ˜азливане на

бензина.

• ‹å çàïóμвайте ка˜бу˜ато˜а, за да сп˜ете двигател.

• ‹икога не ста˜ти˜айте и не ˜аботете с двигател, на който въздуμíè

филтъ˜ен (ако има такъв) комплект е свален.

Когато сменявате маслото

жко изто…вате маслото п˜ез го˜ната т˜ъба за наливане, ˜езе˜воа˜ът за

•

го˜ивото т˜бва да бъде п˜азен, защото в п˜отивен слу…ай мо¥е да има те…

на го˜иво, водещ до по¥а˜ или експлози.

При транспортиране на машината

• ‚˜анспо˜ти˜айте с fiˆжЗЕ‹ ˜езе˜воа˜, или с к˜ан за подаване на го˜иво на

позици OFF.

Когато складирате бензин или оборудване с гориво в резервоара

• Склади˜айте дале… от пещи, пе…ки, водонаг˜еватели или д˜уги елект˜и…ески

п˜ибо˜и, които имат сигнална лампа или д˜уг запалителен изто…ник, защото

те могат да възпламент бензиновите па˜и.

ПРЕДУПРЕЖДЕНИЕ

Пускането на двигателя създава искрене.

Искренето може да възпламени намиращите се наоколо запалими

газове.

Това може да доведе до експлозия и пожар.

• жко има изти…ане на п˜и˜оден или вте…нен газ п˜опан в помещението, не

ста˜ти˜айте двигател.

• ‹е използвайте го˜ива за на…ално запалване под налгане, защото па˜ите им

са запалителни.

12 BRIGGSandSTRATTON.COM

ПРЕДУПРЕЖДЕНИЕ

Двигателите изпускат въглероден окис, който е отровен газ, без

мирис и цвят.

Вдишването на въглероден окис може да причини гадене,

припадък или смърт.

• Ста˜ти˜айте и ˜аботете с двигател навън.

• ‹е ста˜ти˜айте и не ˜аботете с двигател в затво˜ено помещение, до˜и и п˜и

îòâî˜åíè â˜àòè èëè ï˜îçî˜öè.

ПРЕДУПРЕЖДЕНИЕ

Бързото оттегляне на пусковото въже (обратен удар) ще придърпа

изцяло ръката ви към двигателя по-бързо, отколкото вие можете да

я отдръпнете.

Това може да причини счупени кости, фрактури, контузии и

навяхвания.

• яогато ста˜ти˜ате двигател, изтеглете бавно въ¥ето на ста˜те˜а, докато

усетите съп˜отивление, а после ˜зко д˜ъпнете, за да избегнете об˜атни

óäà˜.

• ¤çêë˚…åòå âñêî âúíμно обо˜удване/задви¥вано от двигател, ï˜åäè äà ãî

ñòà˜òè˜àòå.

• Ди˜ектно п˜ика…ените към двигател ìàμинни елементи като но¥ове, пе˜ки,

лебедки, зъбни колела, задви¥ващи ве˜иги и д˜уги, т˜бва да бъдат сигу˜но

п˜ик˜епени.

ПРЕДУПРЕЖДЕНИЕ

Въртящите се части могат да допрат или захванат ръце, крака,

коса, облекло или принадлежности.

Може да се достигне до травматична ампутация или сериозно

нараняване.

• ˆаботете с двигател п˜и поставени защитни капаци.

• Д˜ъ¥те ˜ъцете и к˜аката си дале… от въ˜тùè ñå …àñòè.

• fi˜ивъ˜звайте дългите коси и свалéòå óê˜àμåíèòà.

• ‹е носете по себе си μи˜око облекло, висùè μну˜ове или вещи, които могат

да бъдат захванати.

ПРЕДУПРЕЖДЕНИЕ

Работещите двигатели отделят топлина. Частите на двигателите,

особено шумозаглушителя, стават изключително горещи.

При допир може да получите сериозно изгаряне.

Горимите отпадъци, като листа, треви, храсталак и други, могат да

се запалят.

• ›ставете μумозаглуμèòåë, цилиндъ˜а на двигател è ˜åá˜àòà äà ñå

охладт, п˜еди да ги докосвате.

• ›тст˜анете нат˜упаните отломки около μумозаглуμèòåë и цилиндъ˜а.

• flонти˜айте и поддъ˜¥айте в ˜аботно състоние иск˜огасител, ï˜åäè äà

използвате двигател на залесени места, зат˜евени площи, площи с х˜асти и

необ˜аботени места. Ватът яалифо˜ни изисква това (в ˆаздел 4442 на

яалифо˜нийски п˜авилник за обществени ˜есу˜си). ◊ъзмо¥ноед˜угищати

да имат подобни закони. ·еде˜алните закони се п˜илагат на феде˜ална

те˜ито˜и.

ПРЕДУПРЕЖДЕНИЕ

Случайно искрене може да доведе до пожар или поразяване от

електрически ток.

Неволно стартиране може да доведе до захващане, травматична

ампутация или до раняване.

Опасност от пожар

Преди извършване на настройки и поправки:

• ›тка…ете кабела на запалителната свещ и го д˜ъ¥те дале… от не.

• ›тка…ете минус-клемата на акумулато˜а (само п˜и двигатели с елект˜и…ески

ñòà˜òå˜).

• ¤зползвайте само подходщи инст˜ументи.

• ‹е застопо˜вайте лостовите системи с ˜егули˜ащата п˜у¥ина, или с д˜уги

…àñòè, çà äà ïîâèμите обо˜отите на двигател.

• ˆезе˜вните …асти т˜бва да бъдат със същото ка…ество и да се монти˜ат в

същата позици, както о˜игиналните …асти.

• ‹å óä˜йте маховика с …ук или твъ˜д п˜едмет, защото той мо¥е да се ст˜оμè

по в˜еме на ˜абота.

При изпробване за искра:

• ¤зползвайте одоб˜ен тип тесте˜ за свещи.

• ‹е п˜авете п˜ове˜ка за иск˜а п˜и извадена запалителна свещ.

bg

13

Елементи и управления

С˜авнете ил˚ñò˜àöèòà1ñâàμи двигател, за да се запознаете с

˜азполо¥ението на ˜азли…ните елементи и уп˜авлени.

A. flа˜ки˜овка на двигател

Модел Тип Код

B. Запалителна свещ

C. ˆåçå˜âîà˜ çà ãî˜èâî è êàïà…êà

D. ◊úçäóμен филтъ˜

E. ˆъкохватка на въ¥ето за ˜ъ…ни ñòà˜òå˜

F. ›тво˜ за наливане на масло и нивопоказател

G. fi˜обка за изто…ване на маслото

H. Жумозаглуμèòåë

ÿî¥óõ íà μумозаглуμèòåë (ïî îïöè)

¤ск˜огасител (по опци)

I. ⁄ ост на смука…а

J. ˆú…íà ãàç (ïî îïöè)

K. Ñòîï êë˚…

L. я˜ан…е за подаване на го˜ивото (по опци)

M. fi˜едпазител за п˜ъстите

N. Зъбна ˜едукто˜на кути (ïî îïöè)

Работа

◊местимост за масло (нап˜авете сп˜авка в ˜аздел Технически данни).

Препоръки за маслото

За полу…аване на най-доб˜и техни…ески показатели п˜епо˜ъ…ваме използването

на маслата на Briggs & Stratton с га˜анци и се˜тификат за ка…ество. Д˜уги

високока…ествени масла с миещи п˜исадки са п˜иемливи, ако са класифици˜ани

за ˜аботни ˜е¥ими SF, SG, SH, SJ или по-високи. Да не се използват специални

добавки.

◊úíμните темпе˜ату˜и оп˜еделт п˜авилни вискозитет на маслото за

двигател. ¤зползвайте таблицата, за да избе˜ете най-доб˜и вискозитет за

о…аквани диапазон на вънμните темпе˜ату˜и.

°F °C

SAE 30.

10W-30

Синтетично 5W-30

5W-30

• Ÿензин със съдъ˜¥ание на не пове…е от 10% етанол (бензоспи˜т) или до

15% MTBE (т˜и-метил бутилов ете˜) е п˜иемлив.

ВНИМАНИЕ: ‹е използвайте неодоб˜ени бензини като E85. ‹е смесвайте

бензина с масло, не го модифици˜айте за ˜абота с алте˜нативни го˜ива. ‚ова ще

пов˜еди компонентите на двигател è ще анулира гаранцията му.

За да п˜едпазите го˜ивната система от об˜азуване на смоли, добавете

стабилизато˜ в го˜ивото. ‹ап˜авете сп˜авка в Складиране. шо˜ивата не са едни

същи. жко настъпи п˜облем със ста˜ти˜ането или техни…еските показатели,

сменете достав…иците или ма˜ките на го˜ивото. ‹астоùèтдвигателима

се˜тификат за ˜абота с бензин. Системата за бо˜ба с в˜едните емисии за този

двигател е EM (flодификации на двигателите)

Голяма надморска височина

fi˜и надмо˜ски висо…ини над 5000 фута (1524 мет˜а), бензин с минимално

октаново …исло 85/85 AKI (89 RON), е п˜иемлив. За да остане съвместим с

изискванита за нивото на емисиите, се налага наст˜ойка на двигател â

съответствие с голмата надмо˜ска висо…ина. ˆаботата без такава наст˜ойка ще

доведе до пони¥аване на техни…еските показатели, повиμаване на

консумацита на го˜иво и увели…ени в˜едни емисии. ‹ап˜авете сп˜авка п˜и

‡пълномощен п˜едставител на Briggs & Stratton за сведени относно наст˜ойката

за голма надмо˜ска висо…ина.

‹е се п˜епо˜ъ…ва ˜абота на двигател с ˜егули˜ащ комплект за голма

надмо˜ска висо…ина п˜и висо…ини под 2500 фута (762 мет˜а).

Как да наливаме гориво — Фигура

3

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

При доливане на гориво

• ¤çêë˚…ете двигател и го оставете да се охлади най-малко 2 минути, п˜еди

да свалите капа…ката на ˜езе˜воа˜а за го˜иво.

• fiълнете ˜езе˜воа˜а за го˜иво на отк˜ито или в доб˜е вентили˜ано

помещение.

• ‹е п˜епълвайте ˜езе˜воа˜а за го˜иво. fiълнете го п˜иблизително 1,5 ин…а

(38 mm) по-ниско от го˜ни ˜ъб на гъ˜ловината, за да позволите ˜азμи˜ение

на го˜ивото.

• Д˜ъ¥те бензина дале… от иск˜и, отк˜ити пламъци, сигнални лампи, топлина

и д˜уги запалителни изто…ници.

• fi˜îâå˜вайте …есто го˜ивоп˜оводите, ˜езе˜воа˜а, капа…ката и

съединенита за пукнатини и те…ове. Замен йте ги ако е необходимо.

• жко го˜ивото се ˜азлее, из…акайте докато то се изпа˜и, п˜еди да ста˜ти˜ате

двигател.

1. fiо…истете п˜ост˜анството около капа…ката на ˜езе˜воа˜а за го˜иво от

м˜ъсоти и наслоâàíè. Свалете капа…ката (A). ◊è¥òå ·èãó˜à 3.

2. ‹апълнете ˜езе˜воа˜а за го˜иво (B) с бензин. За да позволите ˜азμи˜ение на

бензина, не пълнете над долната основа на гъ˜ловината за наливане на

го˜иво (C).

3. fiоставете об˜атно капа…ката.

Как да стартирате двигателя — Фигура

4 5

* жко п˜и темпе˜ату˜и под 40°F(4°C) се използва масло SAE 30, това ще

доведе до т˜удно ста˜ти˜ане на двигател.

** fi˜и темпе˜ату˜и над 80°F(27°C) използването на масло 10 W-30 мо¥е да

ïîâèμи консумацита на масло. fi˜îâå˜вайте по …есто нивото му.

Как да проверявате/доливате масло — Фигура

Преди наливане или проверяване на маслото

• ˆазполо¥ете хо˜изонтално двигател.

• fiо…истете мстото около отво˜а за наливане на масло от наслоâàíè.

1. Свалете нивопоказател (A) è ãî èçáú˜μåòå ñ …èñò ïëàò.

2. fiоставете нивопоказател,íîíå ãî çàòгайте. нивото на маслото т˜бва да

бъде до ма˜ки˜овката FULL (B) на нивопокаазател.

3. fi˜и наливане на масло, отливайте внимателно п˜ез отво˜а за пълнене с

масло (C). ‹апълнете до то…ката на п˜епълване.

4. fiоставете отново нивопоказател и го затегнете.

2

Препоръки за горивото

Горивото трябва да отговаря на следните изисквания:

• ˝ист, п˜есен, безоловен бензин.

• flинимално октаново …исло от 87/87 AKI (91 RON). За голма надмо˜ска

âèñî…èíà, âè¥òå ïî-äîëó.

ПРЕДУПРЕЖДЕНИЕ

Бързото оттегляне на пусковото въже (обратен удар) ще придърпа

изцяло ръката ви към двигателя по-бързо, отколкото вие можете да

я отдръпнете.

Това може да причини счупени кости, фрактури, контузии и

навяхвания.

• яогато ста˜ти˜ате двигател, изтеглете бавно въ¥ето на ста˜те˜а, докато

усетите съп˜отивление, а после ˜зко д˜ъпнете, за да избегнете об˜атни

óäà˜.

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

При стартиране на двигателя

• ‡ве˜ете се, …е запалителната свещ, μумозаглуμèòåë, êàïà…êàòà íà

˜езе˜воа˜а за го˜иво и въздуμíè филтъ˜ са на мстото си и са обезопасени.

• ‹е ˜азвъ˜тайте двигател с извадена запалителна свещ.

• жко двигателт се задави, поставете смука…а (ако има такъв) на позици

∆open/run∆, п˜еместете ˜ъ…ната газ (ако има такава) на позици∆fast∆ è

˜азвъ˜тайте, докато двигателò ñòà˜òè˜à.

14 BRIGGSandSTRATTON.COM

ПРЕДУПРЕЖДЕНИЕ

Двигателите изпускат въглероден окис, който е отровен газ, без

мирис и цвят.

Вдишването на въглероден окис може да причини гадене,

припадък или смърт.

• Ста˜ти˜айте и ˜аботете с двигател навън.

• ‹е ста˜ти˜айте и не ˜аботете с двигател в затво˜ено помещение, до˜и и п˜и

îòâî˜åíè â˜àòè èëè ï˜îçî˜öè.

ВНИМАНИЕ: ‹àñòîùèт двигател се достав от Briggs & Stratton без масло.

fi˜еди да ста˜ти˜ате двигател се уве˜ете, …е сте налели масло в него спо˜ед

инст˜укциите в това ˜ъководство. жко го ста˜ти˜ате без масло, той ща се

пов˜еди без да бъде възмо¥но да се ˜емонти˜а и га˜анциòà íма да пок˜ива

щетата.

1. fi˜ове˜ете нивото на маслото. ‹ап˜авете сп˜авка в ˜аздела Êàê ñå

проверява/налива масло.

2. ‡ве˜ете се, …е уп˜авленита на съо˜ъ¥ението, ако има такива, са изкл˚…ени.

‹ап˜авете сп˜авка в ˜ъководството за ˜абота относно местата и ˜аботата с

тези уп˜авлени.

3. ‹атиснете стоп кл˚…à (A) до позициòà (·èãó˜à 4).

4. fi˜еместете ˜ъ…ната газ (B), ако има такава, на бъ˜зата

ˆаботете с двигател íà áú˜çàòà

позици.

позици.

Техническо обслужване

Използвайте единствено оригинални машинни резервни части. Части с друг

произход може да не пасват добре, може да повредят устройството и могат

да доведат до нараняване. ›свен това, използването на …асти с д˜уг п˜оизход

мо¥е да анули˜а ваμàòà ãà˜àíöè.

‹ие ви п˜епо˜ъ…ваме да посетите ›то˜изи˜ан се˜визен п˜едставител на Briggs &

Stratton за вси…ки опе˜ации по техни…еското и се˜визното обслу¥ване на

двигател и ˜езе˜вните …асти.

ВНИМАНИЕ: ◊си…ки компоненти, използвани п˜и п˜оизводството на този

двигател, т˜бва да бъдат на мстото си за п˜авилната му ˜абота.

Контрол на емисиите

Поддръжката, смяната или ремонтът на устройствата за контрол на

вредните емисии могат да бъдат извършвани от всеки ремонтен цех или

техник, ремонтиращи двигатели, които не се използват за транспортни цели.

◊ñå ïàê, çà äà ïîëó…èòå ∆безплатно∆ обслу¥ване на уст˜ойствата за конт˜ол на

в˜едните емисии, ˜аботата т˜áâà äà áúäå èçâú˜μена от упълномощен заводски

п˜едставител. ‹ап˜авете сп˜авка в ша˜анцита относно в˜едните мисли.

ПРЕДУПРЕЖДЕНИЕ

Случайно искрене може да доведе до пожар или поразяване от

електрически ток.

Неволно стартиране може да доведе до захващане, травматична

ампутация или до раняване.

Опасност от пожар

5. fi˜еместете лоста на смука…а (C) на д˜осели˜ана

Забележка: ›бикновено използването на смука… не е необходимо п˜и

повто˜но ста˜ти˜ане на топъл двигател.

6. Завъ˜тете к˜ан…ето за подаване на го˜иво (D), ако има такова, на позици

(·èãó˜à 5).

7. Ръчен стартер: Зд˜аво д˜ъ¥те ˜ъкохватката на въ¥ето на ста˜те˜а (E).

¤зтеглете бавно ˜ъкохватката на въ¥ето на ста˜те˜а, докато по…увствате

съп˜отивление, след което го д˜ъпнете ˜çêî (·èãó˜à 4).

Забележка: жко двигателт не ста˜ти˜а след т˜и опита, идете на ад˜ес

BRIGGSandSTRATTON.COM или се обадете на телефон 1-800-233-3723 (â

ÑæÂ).

ПРЕДУПРЕЖДЕНИЕ: Ÿъ˜зото оттеглíå íà âú¥åòî íà ñòà˜òå˜à

(об˜атен уда˜) ще п˜итегли цлата ви ˜ъка към двигател по-бъ˜зо,

отколкото вие мо¥ете да оттеглите. ‚ова би могло да доведе до с…упени

кости, ф˜акту˜и, навхвани и контузии. fi˜и ста˜ти˜ане на двигател

изтеглете бавно въ¥ето на ста˜те˜а, докато по…увствате съп˜отивление,

след което го д˜ъпнете ˜зко, за да избегнете об˜атни óäà˜.

8. Електрически стартер: Çàâú˜òåòå êë˚…а за елект˜и…ески ста˜те˜ на

позици on/start. ‹ап˜авете сп˜авка в ˜ъководството за ˜абота със

съо˜ъ¥ението относно ˜азполо¥ението и действието с кл˚…à.

Забележка: жко двигателт не ста˜ти˜а след т˜и опита, идете на ад˜ес

BRIGGSandSTRATTON.COM или се обадете на телефон 1-800-233-3723 (â

ÑæÂ).

ВНИМАНИЕ: За да п˜одъл¥ите ¥ивота на ста˜те˜а, използвайте к˜атки

ста˜тови цикли (пет секунди максимум). ¤з…аквайте една минута ме¥ду

отделните ста˜тови цикли.

9. Вом двигателт заг˜ее, поставете лоста на смука…а (C) на ˜аботна

позици (·èãó˜à 4).

Как да спрете двигателя — Фигура

5 6

позици.

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

• ‹å çàïóμвайте каме˜ата на ка˜бу˜ато˜а, за да сп˜ете двигател.

1. ‹атиснете стоп кл˚…à (A, ·игу˜а 6) до позици∆off∆

Електрически стартер: Çàâú˜òåòå êë˚…а за елект˜и…ески ñòà˜òå˜ íà

позици off/stop. ‹ап˜авете сп˜авка в ˜ъководството за ˜абота със

съо˜ъ¥ението относно ˜азполо¥ението и ˜аботата с кл˚…à.

2. След спи˜ане на двигател, завъ˜тете к˜ан…ето за подаване на го˜ивото (D,

·игу˜а 5) на затво˜ено поло¥ение.

èëè

bg

Преди извършване на регулировки и поправки:

• ›тка…ете кабела на запалителната свещ и го д˜ъ¥те дале… от не.

• ¤зползвайте само подходщи инст˜ументи.

• ‹е застопо˜вайте с ˜егули˜ащата п˜у¥ина, лостовите системи или с д˜уги

…àñòè, çà äà ïîâèμите обо˜отите на двигател.

• Replacement parts must be the same and installed in the same position as the

original parts.

• ‹å óä˜йте маховика с …ук или твъ˜д п˜едмет, защото той мо¥е да се ст˜оμè

по в˜еме на ˜абота.

При изпробване за искра:

• ¤зползвайте одоб˜ен тип тесте˜ за свещи.

• ‹е п˜авете п˜ове˜ка за иск˜а п˜и извадена запалителна свещ.

График за техническо обслужване

След първите 5 часа

• Äà ñå ñìåí маслотоl

На всеки 8 часа или ежедневно

• Äà ñå ï˜îâå˜ва нивото на маслото в двигател

• Да се по…истват повъ˜хностите около μумозаглуμèòåë è

уп˜авлениòà.

• Да се по…иства защитни капак за п˜ъстите

На всеки 25 часа или ежегодно

• Да се по…иства въздуμíè филтъ˜ *

• Да се по…иства п˜едфилтъ˜а *

На всеки 100 часа или ежегодно

• Äà ñå ñìåí маслото на двигател

• Äà ñå ï˜åãëå¥äàò μумозаглуμèòåë и иск˜огасител

На всеки 100 часа

• Äà ñå ñìåí маслото в зъбни ˜едукто˜ (ако има такъв)

Ежегодно

• Äà ñå ñìåí въздуμíè филтъ˜.

• Да се смени п˜едфилтъ˜а

• Да се смени запалителната свещ

• Да се по…исти/смени филтъ˜а за го˜ивото

• Да се по…исти въздуμната охладителна система *

• Äà ñå ï˜îâå˜т ме¥дината на клапаните **

* fi˜è íàëè…èå íà çàï˜àμеност или носещи се в околното п˜ост˜анство

отломки, да се по…иства по-…есто.

** ‹е се налага, освен ако не бъдат забелзани п˜облеми с техни…еските

показатели на двигател.

Регулиране на карбуратора

‹е п˜авете никога наст˜ойки на ка˜бу˜ато˜а. яа˜бу˜ато˜ът е ˜егули˜ан в завода

да ˜аботи ефективно п˜и пове…ето околни услови. ◊се пак, ако се налагат

наст˜ойки, се объ˜нете към ‡пълномощен се˜визен на Briggs & Stratton.

ВНИМАНИЕ: fi˜оизводителт на обо˜удването, на което този двигател ще бъде

монти˜ан, оп˜едел максималните обо˜оти, п˜и които ще ˜аботи двигателò. Íå

надвишавайте òåçè îáî˜îòè.

Как да се провери запалителната свещ — Фигура

fi˜îâå˜вайте ме¥дината ме¥ду елект˜одите и (A,·игу˜а8)спомощтана

калибъ˜ за тел (B). жко е необходимо, ˜егули˜айте ме¥дината. flîíòè˜àéòå è

8

15

затегнете свещта с п˜епо˜ъ…вани âú˜òщ момент. За ˜егули˜ане на ме¥дината

или относно въ˜тùè момент за затгане, нап˜авете сп˜авка в ˜аздел

Технически данни.

Забележка: ‹à íкои места, местнит закон изисква упот˜еба на ˜езисто˜на

свещ, за да се подтиснат ˜адиосмущенита. жко настоùèт двигател е

фаб˜и…но обо˜удван с ˜езисто˜на свещ, използвайте същи òèï ñâåù çà ñìíà.

Да се проверява внимателно шумозаглушителя и

искрогасителя — Фигура

7

ПРЕДУПРЕЖДЕНИЕ

Работещите двигатели отделят топлина. Частите на двигателите,

особено шумозаглушителя, стават изключително горещи.

При допир може да получите сериозно изгаряне.

Горимите отпадъци, като листа, треви, храсталак и други, могат да

се запалят.

• ›ставете μумозаглуμèòåë, цилиндъ˜а на двигател è ˜åá˜àòà äà ñå

охладт, п˜еди да ги докосвате.

• ›тст˜анете нат˜упаните отломки около μумозаглуμèòåë и цилиндъ˜а.

• flонти˜айте и поддъ˜¥айте в ˜аботно състоние иск˜огасител, ï˜åäè äà

използвате двигател на залесени места, зат˜евени площи, площи с х˜асти и

необ˜аботени места. Ватът яалифо˜ни изисква това (в ˆаздел 4442 на

яалифо˜нийски п˜авилник за обществени ˜есу˜си). ◊ъзмо¥ноед˜угищати

да имат подобни закони. ·еде˜алните закони се п˜илагат на феде˜ална

те˜ито˜и.

fi˜îâå˜åòå μумозаглуμèòåë (A, ·игу˜а 7) за пукнатини, ко˜ози èëè ä˜óã âèä

пов˜еда. Свалете иск˜огасител (B), ако има такъв, и го п˜ове˜ете за пов˜еда

èëè çàïóμване със са¥ди. жко се налага използването на ˜езе˜вни …асти се

убедете, …е ще бъдат монти˜ани единствено о˜игинални ˜езе˜вни маμèííè

…àñòè.

ПРЕДУПРЕЖДЕНИЕ: ˆезе˜вните …асти т˜бва да бъдат същите

êàòî ñìåíваните и да се монти˜ат в същата позици както о˜игиналните такива,

по˜ади опасност от възникване на по¥а˜.

Системата на въздуμíè филтъ˜ използва филтъ˜ от нагънат филтъ˜ен

мате˜иал с п˜едфилтъ˜ по опци. fi˜едфилтъ˜ът мо¥е да бъде п˜омиван и

ползван повто˜но.

Плосък въздушен филтър

1. ˆазхлабете скобата (D), êîто задъ˜¥а капака (A). ◊è¥òå ·èãó˜à 11.

2. ›тво˜ете капака и свалете п˜едфилтъ˜а (C)ифилтъ˜а(B).

3. За да по…истите наслоâàíèта, леко по…уквайте филтъ˜а въ˜ху твъ˜да

повъ˜хност. жко филтъ˜ът е п˜екоме˜но замъ˜сен, заменете го с нов.

4. fi˜омийте п˜едфилтъ˜а във воден ˜азтво˜ на по…истващ п˜епа˜ат. ›ставете

го доб˜е да се изсуμинавъздух.Íå смазвайте п˜едфилтъ˜а.

5. flîíòè˜àéòå ñóõè п˜едфилтъ˜ с опо˜ни ìó ˜úá (G) към долната ст˜ана на

гънките на филтъ˜а.

6. flонти˜айте филтъ˜а.

7. fiоставете зъб…етата на капака (E)âμлиците (F).

8. Затво˜ете капака и го зак˜епете със скобата.

Как да сменитемаслото в зъбния редуктор — Фигура

жко двигателт ви е обо˜удван със зъбен ˜едукто˜, обслу¥вайте го както

следва.

1. Свалете п˜обката за наливане на масло (B) и п˜обката за п˜ове˜ка на нивото

(C).

2. Свалете п˜обката за изто…ване на маслото (A, ·игу˜а 12) и го изто…ете в

подходщ за целта съд receptacle.

3. fiоставете и затегнете п˜обката за изто…ване на маслото

4. За да напълните отново с масло, внимателно налейте маслото за п˜едавки в

отво˜а за наливане (нап˜авете сп˜авка в ˜аздел Технически данни).

fi˜одъл¥авайте да наливате, докато маслото п˜оте…е извън отво˜а за

п˜ове˜ка на нивото му.

5. fiоставете и затегнете п˜обката за п˜ове˜ка на нивото на маслото.

6. fiоставете и затегнете п˜обката за наливане на масло.

Важно: fi˜обката за наливане на масло има вентилационен отво˜ (D)èò˜áâà

да бъде поставена отго˜е на капака на ˜едукто˜а, както е показано.

12

Как да почиствате/сменяте филтъра за

горивото — Фигура

13

Как да се сменя маслото — Фигура

ВНИМАНИЕ: ›т˜аботилото масло е опасен отпадъ…ен п˜одукт и т˜áâà äà ñå

склади˜а по подходщ на…ин. ‹е го изхвъ˜лйте с домакинските отпадъци.

fi˜ове˜ете съвместно с общинските власти, за обслу¥ващ центъ˜ или з а

п˜едставител на инсталации за безопасно депони˜ане/˜ецикли˜ане на

от˜аботилото масло.

9 10

Източете отработилото масло

1. fi˜è èçêë˚…ен, но все още топъл двигател, отка…ете кабела на запалителната

ñâåù (A) и го д˜ъ¥те на ˜азстоние от свещта (·игу˜а 10).

2. Свалете п˜обката за изто…ване на маслото (B, ·игу˜а 9). ¤зто…ете маслото в

подходщ за целта съд.

Забележка: ◊ñка от показаните п˜обки за изто…ване на маслото (C)ìî¥åäà

бъде монти˜ана на двигател.

3. След като маслото е изто…ено, поставете и затегнете п˜обката.

Наливане на масло

• ˆазполо¥ете хо˜изонтално двигател.

• fiо…истете мстото около отво˜а за наливане на масло от вси…ки отломки.

• ‹ап˜авете сп˜авка в ˜аздел Технически данни относно вместимостта за

маслото.

1. Свалете нивопокаазател (D) è ãî èçáú˜μåòå ñ …èñò ïëàò.

2. ‹алейте внимателно масло в двигател п˜ез отво˜а за наливане (E).

‹апълнете до то…ката на п˜еливане.

3. fiоставете нивопоказател,íîíå ãî çàòгайте. Свалете го и п˜ове˜ете

нивото на маслото. ‚о т˜бва да достига до ма˜ки˜овката FULL (F)на

нивопоказател.

4. flонти˜айте и затегнете нивопоказател.

Как да се обслужва въздушния филтър — Фигура

11

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

• ‹икога не ста˜ти˜айте и не ˜аботете с двигател п˜и свален филтъ˜ен

комплект или въздуμен филтъ˜.

ВНИМАНИЕ: ‹е използвайте сгъстен въздух или ˜азтво˜ители, за да по…иствате

филтъ˜а. Сгъстенит въздух мо¥е да пов˜еди филтъ˜а, а ˜азтво˜ителите го

˜азтва˜ò.

16

ПРЕДУПРЕЖДЕНИЕ

Бензинът и неговите пари са изключително огнеопасни и

избухливи.

Пожар или взрив могат да причинят сериозни обгаряния или смърт.

• Д˜ъ¥те бензина дале… от иск˜и, отк˜ити пламъци, сигнални лампи, топлина

и д˜уги запалителни изто…ници.